At their core, silicon carbide (SiC) heating elements enhance the heat treatment of alloys by providing exceptional temperature uniformity, high-temperature capability, and a chemically stable operating environment. This combination ensures that every part of an alloy component undergoes the precise thermal cycle required to achieve its target mechanical properties, such as hardness and corrosion resistance, with a high degree of consistency and repeatability.

The challenge in heat treatment isn't just reaching a high temperature; it's achieving the exact temperature uniformly across a component to control its microscopic structure. Silicon carbide elements provide the precise and stable thermal control necessary to master this metallurgical transformation.

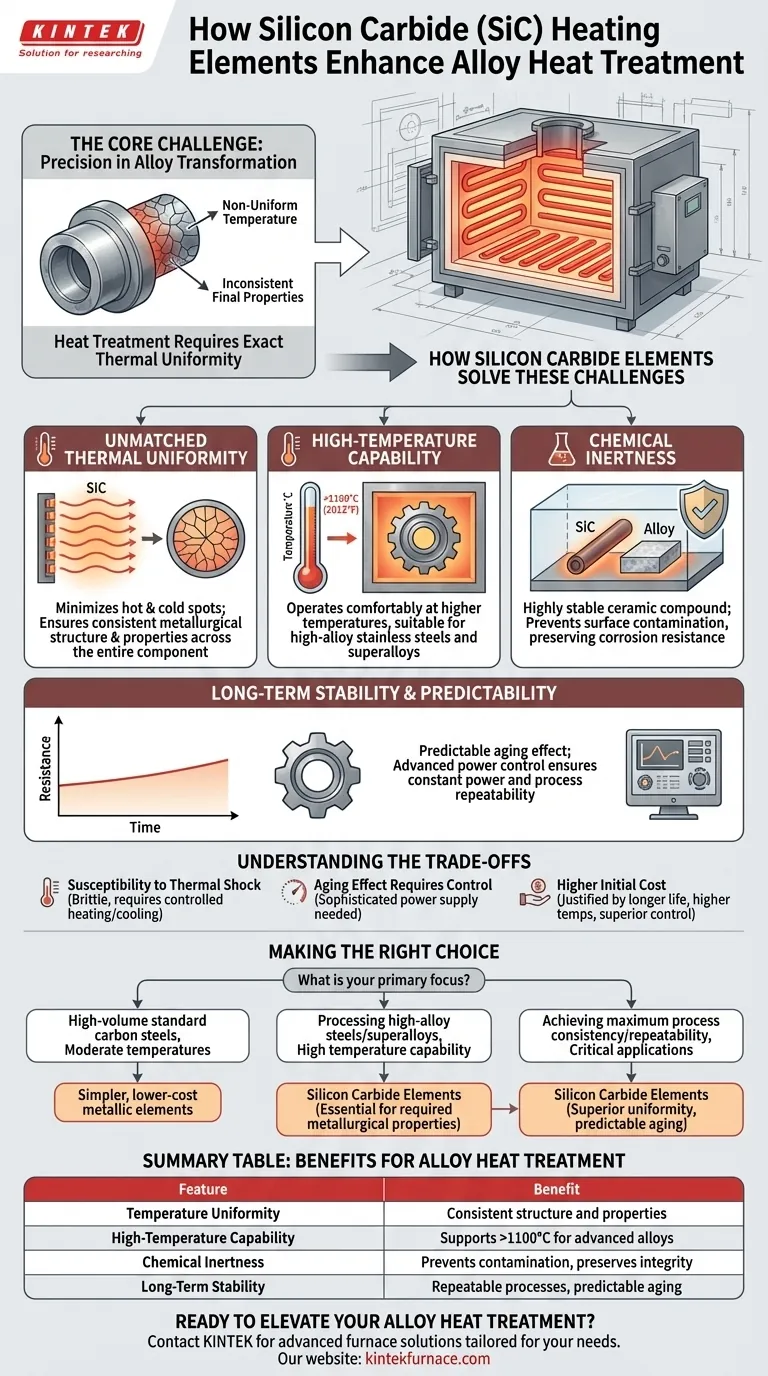

The Core Challenge: Precision in Alloy Transformation

Heat treatment is a process of controlled heating and cooling to alter the physical and chemical properties of a material. For metal alloys, this process is fundamentally about controlling phase transformations and grain structure.

Why Temperature Uniformity is Non-Negotiable

Alloys like steel transform from one crystalline structure to another (e.g., ferrite to austenite) at very specific temperatures. If a furnace has hot and cold spots, different parts of the same component will transform at different rates or to different extents.

This non-uniformity leads directly to inconsistent final properties. One area might be perfectly hardened, while another remains too soft, creating internal stresses and a critical point of failure.

The Problem of Process Environment

The atmosphere within a furnace can be reactive, especially at high temperatures. Elements that outgas or react with the protective atmosphere can contaminate the surface of the alloy, compromising its integrity and corrosion resistance.

How Silicon Carbide Elements Solve These Challenges

Silicon carbide's material properties make it uniquely suited to overcome the core challenges of high-performance heat treatment. It moves beyond simple heating to become a tool for process control.

Unmatched Thermal Uniformity

SiC elements radiate heat very evenly across their entire surface. This creates a highly uniform thermal environment within the furnace chamber, minimizing hot and cold spots.

This uniformity ensures the entire alloy workpiece, regardless of its size or geometry, experiences the same thermal conditions. The result is a consistent and predictable metallurgical structure across the entire part.

High-Temperature Capability

Many advanced alloys, including high-alloy stainless steels and superalloys, require heat treatment temperatures above 1100°C (2012°F), which can push the limits of traditional metallic heating elements.

Silicon carbide elements operate comfortably at these higher temperatures, allowing for the proper treatment of a wider range of high-performance materials without risk of element failure.

Chemical Inertness

SiC is a highly stable ceramic compound. It does not readily react with common furnace atmospheres or the materials being processed.

This inertness prevents contamination of the alloy surface, preserving its chemical composition and ensuring that properties like corrosion resistance are not compromised by the heating process itself.

Long-Term Stability and Predictability

While the electrical resistance of SiC elements increases slowly over their operational life—a phenomenon known as aging—this process is well-understood and highly predictable.

Advanced power control systems can automatically compensate for this change, ensuring that the power output and furnace temperature remain constant from one cycle to the next. This delivers the process repeatability essential for quality control in critical applications.

Understanding the Trade-offs

While highly effective, SiC elements are not a universal solution. Acknowledging their specific operational requirements is key to successful implementation.

Susceptibility to Thermal Shock

As a ceramic material, SiC is more brittle than metallic elements. Rapid, uncontrolled temperature changes can cause mechanical stress and lead to fractures. A controlled heat-up and cool-down rate is essential.

The Aging Effect Requires Control

The predictable increase in resistance requires a power supply, typically using a Silicon-Controlled Rectifier (SCR), that can adjust the voltage to maintain constant power. This is a more sophisticated control requirement compared to simple metallic elements.

Higher Initial Cost

The initial investment for SiC elements and their associated power control systems is typically higher than for standard metallic element systems. This cost is justified by their longer lifespan in demanding applications, higher temperature capabilities, and superior process control.

Making the Right Choice for Your Heat Treatment Process

Selecting the correct heating element is a foundational decision that directly impacts product quality, process efficiency, and operational cost.

- If your primary focus is high-volume production of standard carbon steels: Simpler, lower-cost metallic elements may be sufficient if your process temperatures are moderate and uniformity requirements are less stringent.

- If your primary focus is processing high-alloy steels or superalloys: The high-temperature capability and chemical inertness of silicon carbide are essential for achieving the required metallurgical properties.

- If your primary focus is achieving maximum process consistency and repeatability: The superior thermal uniformity and predictable aging of SiC elements provide the process control needed for critical components in industries like aerospace or medical.

Ultimately, choosing the right heating technology is the first step toward achieving absolute control over your metallurgical outcomes.

Summary Table:

| Feature | Benefit for Alloy Heat Treatment |

|---|---|

| Temperature Uniformity | Ensures consistent metallurgical structure and properties across the alloy |

| High-Temperature Capability | Supports heat treatment above 1100°C for advanced alloys like superalloys |

| Chemical Inertness | Prevents contamination, preserving alloy integrity and corrosion resistance |

| Long-Term Stability | Enables repeatable processes with predictable aging and power control |

Ready to elevate your alloy heat treatment with precision and reliability?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories and industrial applications. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs.

Whether you're processing high-alloy steels or superalloys, our silicon carbide heating elements ensure superior temperature control, uniformity, and chemical stability for consistent results.

Contact us today to discuss how we can optimize your heat treatment processes and deliver the performance your projects demand!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element