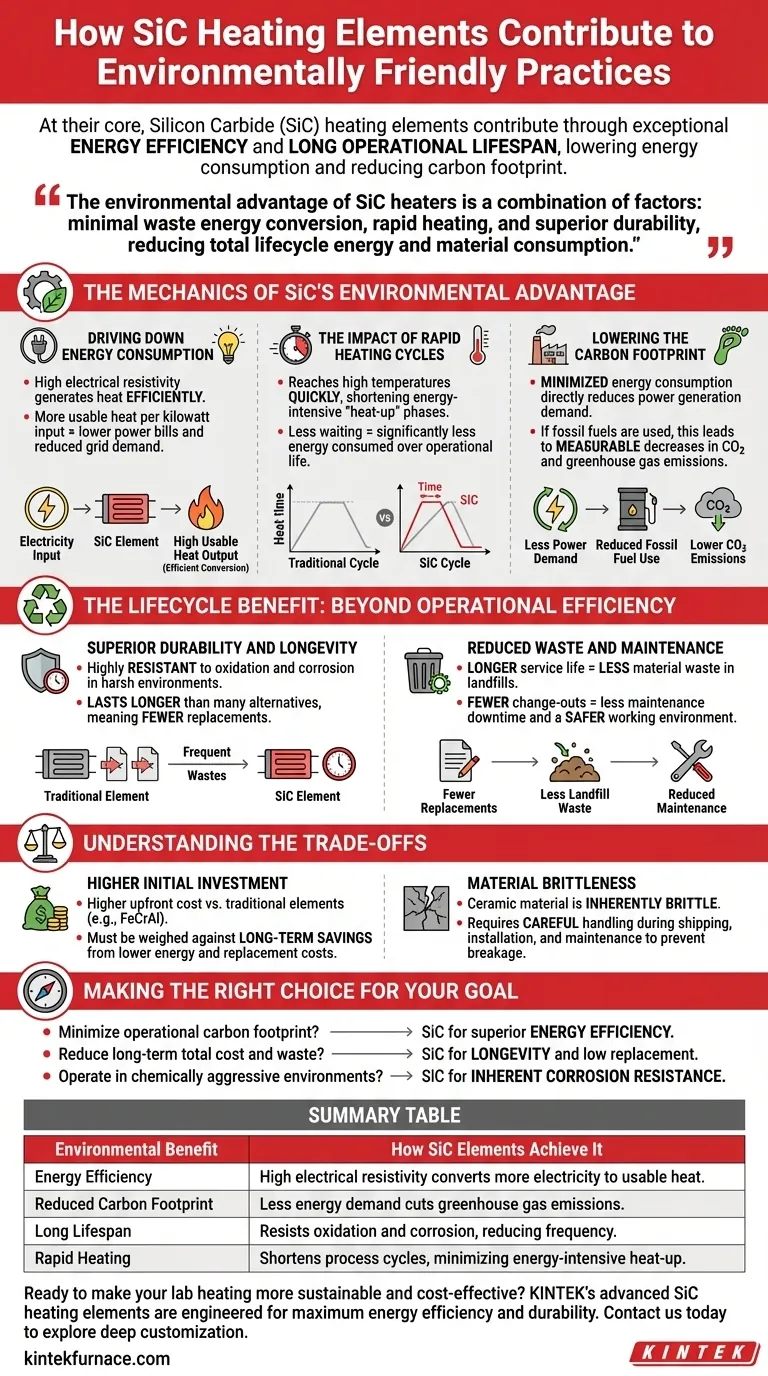

At their core, Silicon Carbide (SiC) heating elements contribute to environmentally friendly practices through their exceptional energy efficiency, which directly lowers energy consumption and reduces the carbon footprint of industrial heating processes. Their long operational lifespan further minimizes environmental impact by reducing waste and the need for frequent replacements.

The environmental advantage of SiC heaters is not a single feature, but a combination of factors. It stems from their ability to convert electricity to heat with minimal waste, their rapid heating capability, and their superior durability, which collectively reduce both energy and material consumption over the element's entire lifecycle.

The Mechanics of SiC's Environmental Advantage

To understand the environmental benefits, we must look at how these elements function. The advantages are rooted in their material properties and how they perform within a heating system.

Driving Down Energy Consumption

Silicon Carbide is a semiconductor material with high electrical resistivity. When electricity passes through it, it generates heat 매우 efficiently, minimizing the amount of energy lost in the process.

This high efficiency means that for every kilowatt of energy you put in, you get more usable heat out compared to less efficient, older technologies. This directly translates to lower power bills and reduced demand on the electrical grid.

The Impact of Rapid Heating Cycles

SiC elements can reach very high operating temperatures quickly. This rapid thermal response 건물 process cycle times and, crucially, shortens the energy-intensive "heat-up" phase of any operation.

Furnaces and kilns that spend less time waiting to reach their target temperature consume significantly less energy over მათი operational life, enhancing overall industrial sustainability.

Lowering the Carbon Footprint

The primary way any electrically powered device lowers its carbon footprint is by using less electricity. By minimizing energy consumption through efficiency and fast heating, SiC elements directly reduce the demand for power generation.

When that power is generated from fossil fuels, this reduction obstáculos in a direct and measurable decrease in carbon dioxide (CO2) and other greenhouse gas emissions.

The Lifecycle Benefit: Beyond Operational Efficiency

A component's environmental impact प्रोटीनt just about its performance when running. It also includes its manufacturing, lifespan, and disposal. Here, SiC elements also provide a significant advantage.

Superior Durability and Longevity

SiC is highly resistant to oxidation and chemical corrosion, even in harsh, high-temperature environments. This robustness allows SiC elements to last 엔진 than many alternatives.

A longer service life means fewer replacements are needed over time. This reduces the environmental impact associated with manufacturing new elements, including raw material extraction, energije consumption, and shipping.

Reduced Waste and Maintenance

Because they last longer, SiC elements contribute less матеріалу waste to landfills. The need for fewer change-outs also translates to less maintenance downtime and a safer working environment.

Understanding the Trade-offs

No technology is a perfect solution for every scenario. To make an informed decision, you must be aware of the practical considerations.

Higher Initial Investment

SiC heating elements typically have a higher upfront procurement cost compared to traditional metallic elements like Kanthal (FeCrAl). This initial expense must be weighed against the long-term savings from lower energy consumption and reduced replacement frequency.

Material Brittleness

Silicon Carbide is a ceramic material and is inherently more brittle than metallic alloys. This característica requires more careful handling during shipping, installation, and maintenance to prevent fractures or breakage.

Making the Right Choice for Your Goal

Your final decision should be based on a clear understanding of your primary objective.

- If your primary focus is minimizing operational carbon footprint: The superior energy efficiency of SiC elements makes them the clear choice for reducing day-to-day energy consumption.

- If your primary focus is reducing long-term total cost and waste: The longevity and low replacement rate of SiC elements often justify their higher initial cost over the full life of the equipment.

- If you are operating in a chemically aggressive or high-oxidation environment: The inherent corrosion resistance of SiC provides a distinct advantage for both operational reliability and environmental sustainability.

By evaluating these factors, you can confidently select a heating solution that aligns with both your performance requirements and your sustainability goals.

Summary Table:

| Environmental Benefit | How SiC Elements Achieve It |

|---|---|

| Energy Efficiency | High electrical resistivity converts more electricity to usable heat, lowering consumption. |

| Reduced Carbon Footprint | Less energy demand cuts greenhouse gas emissions from power generation. |

| Long Lifespan | Resists oxidation and corrosion, reducing replacement frequency and material waste. |

| Rapid Heating | Shortens process cycles, minimizing energy-intensive heat-up phases. |

Ready to make your lab heating more sustainable and cost-effective? KINTEK’s advanced SiC heating elements are engineered for maximum energy efficiency and durability, directly reducing your operational costs and environmental impact. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance solutions tailored to your unique needs. Contact us today to explore how our deep customization capabilities can enhance your sustainability goals!

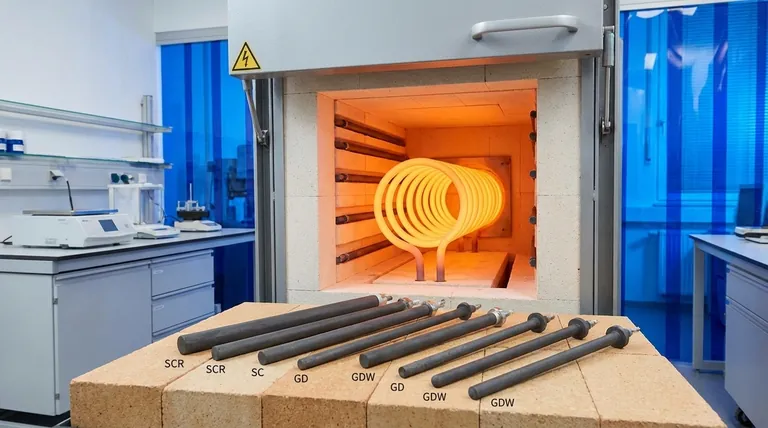

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism