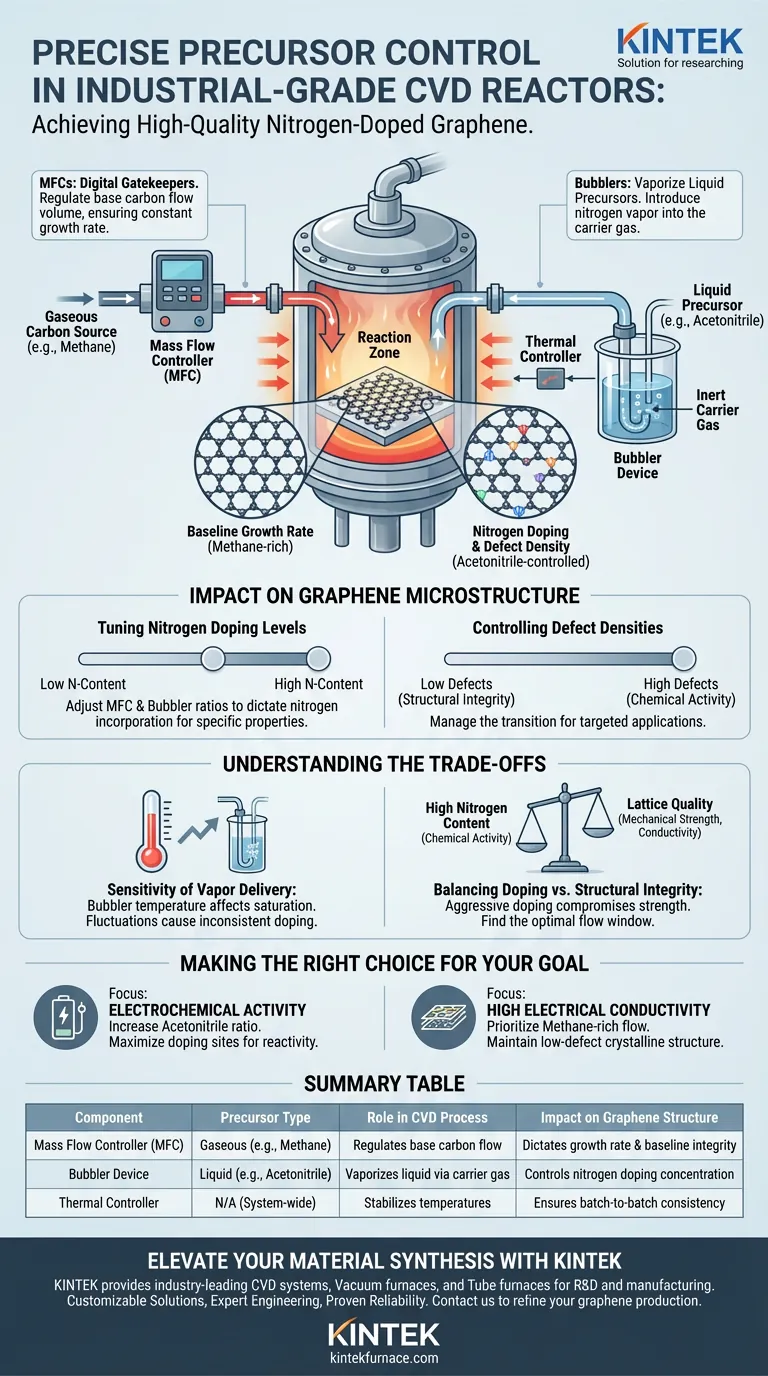

Industrial-grade vacuum CVD reactors achieve precise precursor control by integrating Mass Flow Controllers (MFCs) with specialized bubbler devices. These systems work in tandem to rigorously regulate the flow rates and specific ratios of gaseous carbon sources, such as methane, and liquid vapors, like acetonitrile, entering the reaction zone.

Precision in precursor flow is not just about delivery; it is the primary lever for engineering the material's atomic structure, allowing operators to fine-tune nitrogen doping concentrations and manage defect densities within the graphene lattice.

The Mechanics of Precursor Regulation

The Role of Mass Flow Controllers (MFCs)

MFCs serve as the digital gatekeepers of the Chemical Vapor Deposition process.

They provide real-time feedback and control over the volume of gas entering the chamber.

By strictly governing the flow of the primary carbon source, typically methane, MFCs ensure the baseline growth rate of the graphene remains constant.

Integrating Bubbler Devices for Liquid Precursors

To introduce nitrogen into the lattice, the system often utilizes acetonitrile, which exists as a liquid at room temperature.

Bubbler devices are employed to vaporize this liquid.

An inert carrier gas or the reactant gas itself bubbles through the liquid acetonitrile, carrying precise amounts of vapor into the reactor to mix with the methane.

Impact on Graphene Microstructure

Tuning Nitrogen Doping Levels

The ratio of acetonitrile vapor to methane gas is the critical variable.

By adjusting the MFC settings and bubbler parameters, operators can dictate exactly how much nitrogen is available for incorporation.

This allows for the creation of nitrogen-doped three-dimensional graphene with specific electrical and chemical properties tailored to the application.

Controlling Defect Densities

The introduction of heteroatoms like nitrogen inevitably creates defects in the perfect carbon lattice.

Precise flow control allows for the management of the transition between low-defect and high-defect structures.

This capability is essential, as different applications require different defect densities—some require high structural integrity, while others benefit from the chemical reactivity of defects.

Understanding the Trade-offs

The Sensitivity of Vapor Delivery

While bubblers enable the use of liquid precursors, they introduce complexity regarding saturation levels.

The amount of vapor picked up by the carrier gas is highly dependent on the temperature of the liquid in the bubbler.

If the bubbler temperature fluctuates, the doping ratio changes, potentially leading to inconsistent batch-to-batch results.

Balancing Doping vs. Structural Integrity

There is an inherent trade-off between high nitrogen content and lattice quality.

Aggressive doping (high acetonitrile flow) increases chemical activity but compromises the mechanical strength and conductivity of the graphene.

Operators must find the optimal flow window where the material retains its structural scaffold while achieving the desired doping level.

Making the Right Choice for Your Goal

To optimize your nitrogen-doped graphene synthesis, you must align your flow control strategy with your end-application requirements:

- If your primary focus is high electrical conductivity: Prioritize a methane-rich flow ratio to maintain a low-defect crystalline structure with minimal nitrogen disruption.

- If your primary focus is electrochemical activity (e.g., for batteries or sensors): Increase the acetonitrile vapor ratio to maximize nitrogen doping sites and deliberately induce catalytically active defects.

Mastering the interplay between MFC settings and bubbler dynamics is the key to transitioning from random growth to engineered material synthesis.

Summary Table:

| Component | Precursor Type | Role in CVD Process | Impact on Graphene Structure |

|---|---|---|---|

| Mass Flow Controller (MFC) | Gaseous (e.g., Methane) | Regulates base carbon flow volume | Dictates growth rate & baseline integrity |

| Bubbler Device | Liquid (e.g., Acetonitrile) | Vaporizes liquid via carrier gas | Controls nitrogen doping concentration |

| Thermal Controller | N/A (System-wide) | Stabilizes bubbler & zone temp | Ensures batch-to-batch doping consistency |

Elevate Your Material Synthesis with KINTEK

Precision in nitrogen-doped graphene synthesis requires more than just high-quality precursors—it demands a reactor engineered for absolute control. KINTEK provides industry-leading CVD systems, Vacuum furnaces, and Tube furnaces designed to meet the rigorous demands of advanced R&D and large-scale manufacturing.

Why choose KINTEK?

- Customizable Solutions: Tailor MFC configurations and bubbler integrations to your specific chemical vapor deposition needs.

- Expert Engineering: Benefit from our deep R&D expertise in high-temperature lab equipment.

- Proven Reliability: Achieve consistent doping ratios and structural integrity across every batch.

Ready to refine your graphene production? Contact us today to discuss your unique project requirements and see how our customizable furnace systems can transform your laboratory's capabilities.

Visual Guide

References

- Kavitha Mulackampilly Joseph, Vesselin Shanov. Modified 3D Graphene for Sensing and Electrochemical Capacitor Applications. DOI: 10.3390/nano14010108

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

People Also Ask

- What is the role of a horizontal oxidation furnace? Enhancing Silicon Micro-Tip Diffusion Barriers

- How do sapphire and silicon dioxide substrates differ in CVD growth of VSe2? Choose the Right Growth Surface

- What happens during the chemical reactions in CVD? Master Thin Film Deposition for Your Lab

- What are some common applications of Chemical Vapor Deposition? Unlock High-Performance Thin Films for Your Industry

- In what way are CVD systems applied to gas purification? Engineer Advanced Catalysts for Cleaner Synthesis Gas

- What are the advantages and disadvantages of physical Vapour deposition? A Guide to High-Performance Thin Films

- What are the disadvantages of CVD? Weighing High Costs, Complexity, and Constraints

- What are the advantages of using CVD for CNC machining? Boost Durability and Efficiency in Precision Parts