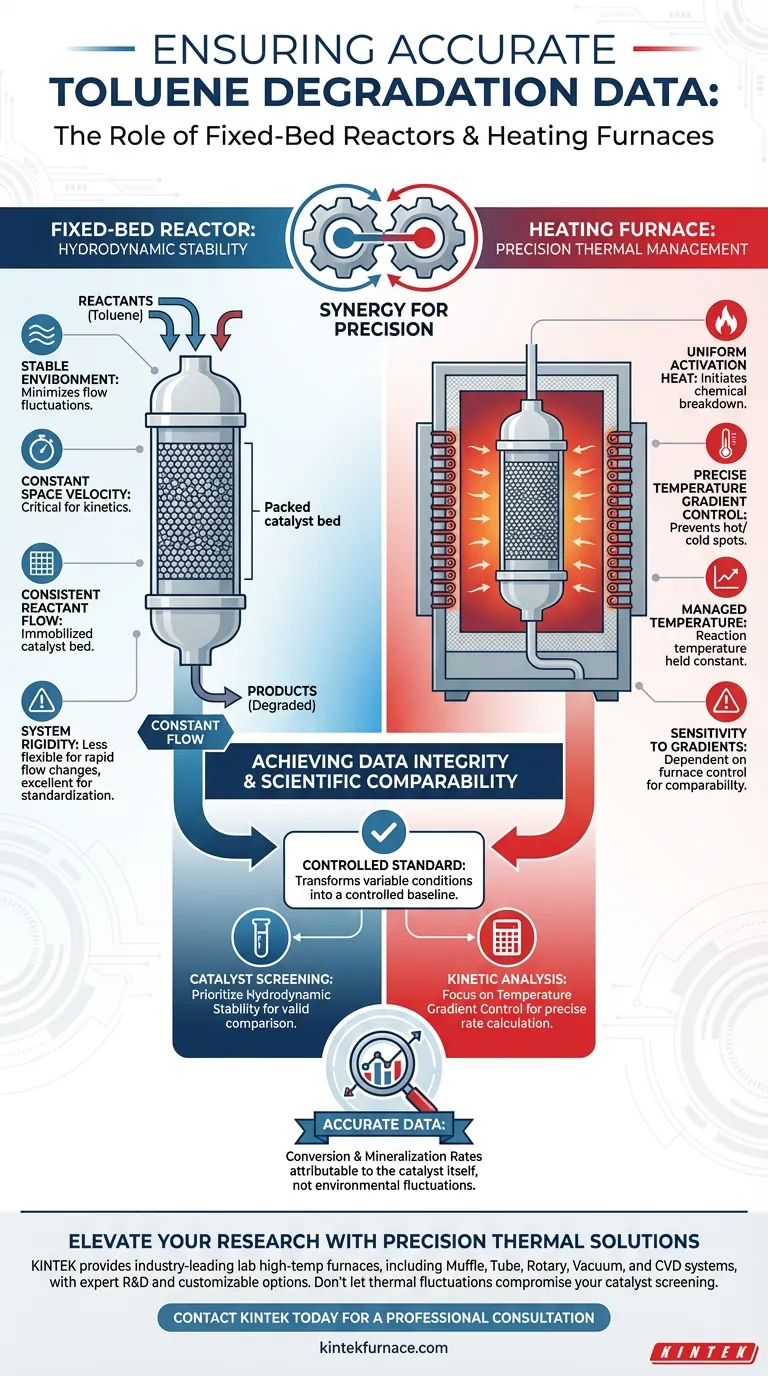

Accurate toluene degradation data depends on the precise synchronization of flow and heat. A fixed-bed reactor secures the hydrodynamic environment, while a heating furnace delivers necessary activation energy through rigorous temperature gradient control. This combination creates a baseline where critical parameters—specifically space velocity, temperature, and reactant concentration—remain constant throughout the experiment.

The synergy between the reactor and furnace transforms variable experimental conditions into a controlled standard. This ensures that any observed changes in conversion or mineralization rates are attributable to the catalyst itself, not fluctuations in the test environment.

Establishing Environmental Stability

The Role of the Fixed-Bed Reactor

The primary function of the fixed-bed reactor in this context is to provide a stable hydrodynamic environment. By immobilizing the catalyst bed, the reactor ensures that the flow of reactants remains consistent physically.

Controlling Hydrodynamics

Fluctuations in how gas flows over a catalyst can introduce massive errors in data. The fixed-bed design minimizes these disturbances. This stability allows researchers to maintain a constant space velocity, which is critical for calculating reaction kinetics accurately.

Precision Thermal Management

Delivering Activation Heat

Toluene degradation requires significant energy to initiate the chemical breakdown. The heating furnace provides this necessary activation heat. Without a reliable external heat source, the reaction would either not occur or proceed at rates too slow to measure effectively.

Managing Temperature Gradients

It is not enough to simply heat the reactor; the heat must be applied uniformly. The furnace ensures precise temperature gradient control. This prevents "hot spots" or "cold zones" within the reactor, which could otherwise skew the data by altering the reaction rate in specific sections of the catalyst bed.

Achieving Data Integrity

Standardizing Key Parameters

For data to be valid, the variables must be isolated. The combined setup ensures that reaction temperature and reactant concentration are held constant alongside space velocity. This isolation is the bedrock of experimental accuracy.

Ensuring Scientific Comparability

When parameters are stabilized, the data generated regarding conversion and mineralization rates becomes scientifically comparable. This allows researchers to confidently compare the performance of various catalysts, knowing the differences are real and not artifacts of the equipment.

Understanding the Trade-offs

Sensitivity to Gradient Deviations

While this setup offers high precision, it is heavily dependent on the furnace's ability to maintain the temperature gradient. Even minor failures in gradient control can reintroduce variables that compromise the comparability of the data.

System Rigidity

A fixed-bed reactor is designed for stability, but this can also limit flexibility. The "fixed" nature of the hydrodynamic environment makes it excellent for standardizing space velocity, but it may be less adaptable for experiments requiring rapid, dynamic changes in flow patterns compared to fluidized beds.

Making the Right Choice for Your Experiment

To maximize the value of your toluene degradation data, align your equipment usage with your specific analytical goals:

- If your primary focus is Catalyst Screening: Prioritize hydrodynamic stability to ensure that space velocity is identical across all tests, making catalyst comparison valid.

- If your primary focus is Kinetic Analysis: Focus on the furnace's temperature gradient control to ensure activation heat is uniform, allowing for precise calculation of reaction rates.

By strictly controlling the physical and thermal environment, you move from simple observation to rigorous scientific validation.

Summary Table:

| Feature | Role in Experiment | Impact on Data Accuracy |

|---|---|---|

| Fixed-Bed Reactor | Hydrodynamic Stability | Ensures constant space velocity and consistent reactant flow. |

| Heating Furnace | Thermal Management | Provides uniform activation heat and eliminates temperature gradients. |

| Controlled Parameters | Environmental Standardization | Isolates variables to ensure conversion rates are catalyst-dependent. |

| Data Output | Scientific Comparability | Enables valid kinetic analysis and performance screening. |

Elevate Your Research with Precision Thermal Solutions

Achieving accurate reaction data requires equipment that eliminates variables. KINTEK provides industry-leading lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—engineered to deliver the rigorous temperature gradient control your toluene degradation experiments demand.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet your unique reactor specifications and hydrodynamic requirements. Don't let thermal fluctuations compromise your catalyst screening.

Contact KINTEK Today for a Professional Consultation

Visual Guide

References

- Xiaojian Wang, Hao Huang. Synergistic oxidation of toluene through bimetal/cordierite monolithic catalysts with ozone. DOI: 10.1038/s41598-024-58026-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ Muffle Oven Furnace for Laboratory

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why Calcination of Carbon-Supported Nickel Catalysts Needs Inert Gas? Protect Your Support Structure

- What role does atmosphere control play in ruthenium loading for catalyst synthesis? Master Precision Kinetics

- What are the limitations of low vacuum atmosphere furnaces? Understand Trade-offs for Cost-Effective Heat Treatment

- What are the key applications of a controlled atmosphere furnace? Unlock Precise Material Processing

- Why compare air and nitrogen atmospheres in CZTS post-annealing? Isolate Oxygen's Impact for Higher Efficiency

- Why is a continuous belt furnace with a controlled atmosphere required for sintering powder metallurgy steel?

- What role does an atmosphere furnace play in industrial-scale production? Unlock Precision in High-Temperature Processing

- What is the primary structural difference between a muffle furnace and an atmosphere furnace? Control Gas for Better Results