To achieve the mechanical integrity required for industrial applications, sintering powder metallurgy steel demands a continuous belt furnace with a controlled atmosphere. This specific setup ensures a stable thermal environment—typically around 1125°C—while utilizing reducing gases like Hydrogen and Nitrogen to eliminate oxygen, preventing oxidation and allowing metal particles to fuse through molecular diffusion.

Core Takeaway: A continuous belt furnace provides the thermal stability and chemical protection necessary to transform porous powder compacts into dense, high-strength steel components by facilitating "sintering neck" formation without the interference of metal oxides.

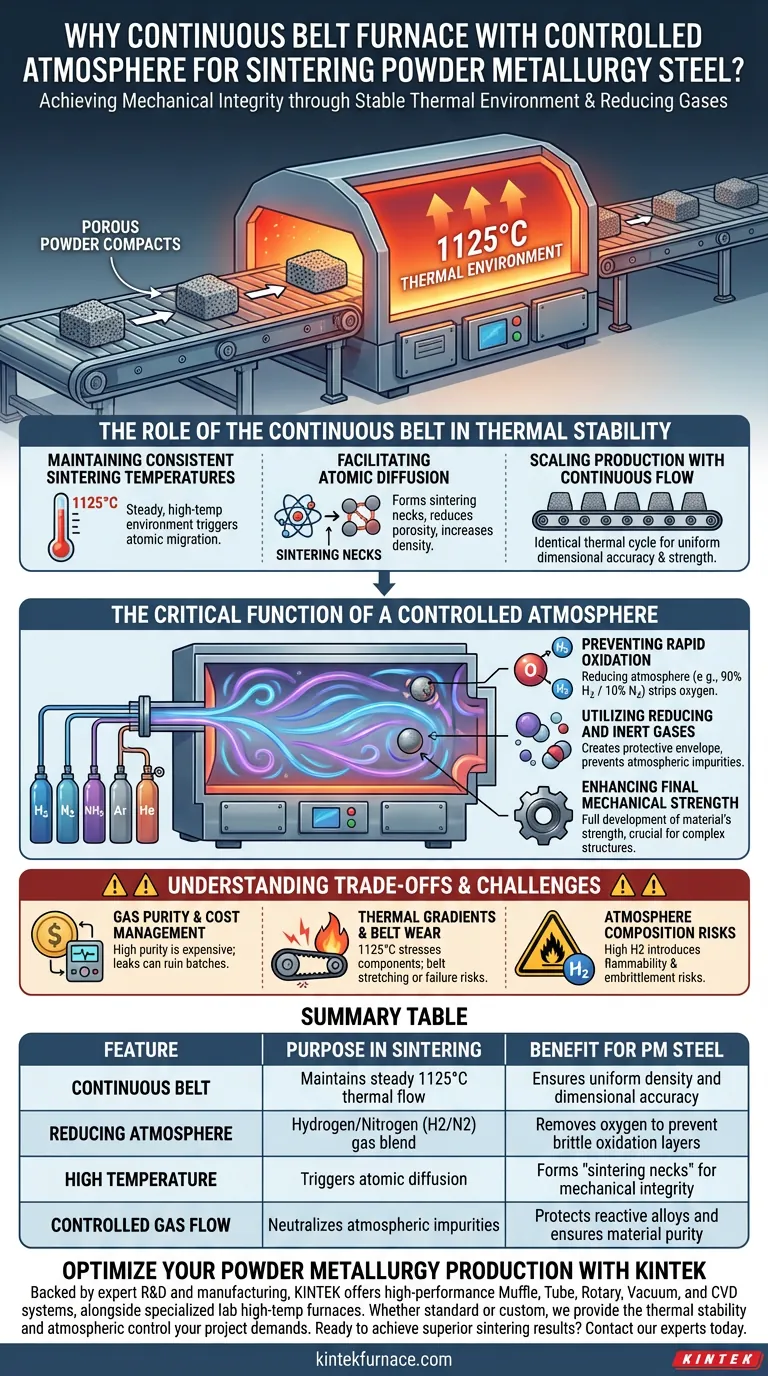

The Role of the Continuous Belt in Thermal Stability

Maintaining Consistent Sintering Temperatures

A continuous belt furnace is engineered to maintain a steady, high-temperature environment, often calibrated to 1125°C. This stability is vital because sintering relies on precise thermal energy to trigger the migration of atoms across particle boundaries.

Facilitating Atomic Diffusion

At these elevated temperatures, steel particles undergo a material transfer phenomenon known as diffusion. As atoms move, they form "sintering necks" between individual powder grains, which gradually reduces the part's porosity and increases its density.

Scaling Production with Continuous Flow

Unlike batch processes, a belt furnace allows for a steady flow of components through various heating zones. This ensures that every part experiences an identical thermal cycle, which is critical for maintaining dimensional accuracy and uniform mechanical strength across large production runs.

The Critical Function of a Controlled Atmosphere

Preventing Rapid Oxidation

High-temperature steel is extremely reactive to oxygen; without a controlled atmosphere, the metal would oxidize instantly, creating a brittle layer that prevents bonding. By using a reducing atmosphere—often a mix of 90% H2 and 10% N2—the furnace actively strips oxygen away from the metal surface.

Utilizing Reducing and Inert Gases

In addition to hydrogen-nitrogen blends, some processes utilize decomposed ammonia (NH3) or noble gases like Argon and Helium. These gases create a protective envelope that ensures the metallurgical bonding process remains uncontaminated by atmospheric impurities.

Enhancing Final Mechanical Strength

By eliminating oxygen and promoting a clean environment, the atmosphere allows for the full development of the material's final mechanical strength. This is especially important for complex structures, such as porous foams or high-stress automotive components, where internal bonding is the primary source of durability.

Understanding the Trade-offs and Challenges

Gas Purity and Cost Management

Maintaining a high-purity reducing atmosphere is expensive and requires sophisticated monitoring systems. Any leak or drop in gas quality can lead to surface decarburization or oxidation, potentially ruining an entire production batch.

Thermal Gradients and Belt Wear

Operating at 1125°C puts significant stress on the furnace's internal components and the belt itself. Constant thermal cycling or uneven loading can lead to belt stretching or mechanical failure, necessitating regular maintenance and precise calibration of the transport speed.

Atmosphere Composition Risks

Using high concentrations of Hydrogen (H2) introduces safety risks, including flammability and potential hydrogen embrittlement if not managed correctly. Engineers must balance the chemical reactivity of the atmosphere with the specific alloy requirements of the steel powder being processed.

Making the Right Choice for Your Goal

When selecting a sintering environment, your specific material requirements and production volume should dictate the furnace configuration and atmosphere choice.

- If your primary focus is high-volume consistency: A continuous belt furnace is the industry standard for ensuring every part reaches the required density through uniform thermal exposure.

- If your primary focus is preventing surface oxidation: Prioritize a reducing atmosphere using H2/N2 or decomposed ammonia to ensure clean particle-to-particle diffusion.

- If your primary focus is specialized or reactive alloys: Consider a controlled atmosphere using inert gases like Argon or even vacuum sintering to avoid unwanted chemical reactions at high temperatures.

By mastering the balance between thermal energy and chemical protection, you can reliably transform loose metal powders into high-performance steel components.

Summary Table:

| Feature | Purpose in Sintering | Benefit for PM Steel |

|---|---|---|

| Continuous Belt | Maintains steady 1125°C thermal flow | Ensures uniform density and dimensional accuracy |

| Reducing Atmosphere | Hydrogen/Nitrogen (H2/N2) gas blend | Removes oxygen to prevent brittle oxidation layers |

| High Temperature | Triggers atomic diffusion | Forms "sintering necks" for mechanical integrity |

| Controlled Gas Flow | Neutralizes atmospheric impurities | Protects reactive alloys and ensures material purity |

Optimize Your Powder Metallurgy Production with KINTEK

Don't let oxidation or inconsistent heating compromise your mechanical strength. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab high-temp furnaces. Whether you need standard belt furnace solutions or customizable systems for unique alloy requirements, we provide the thermal stability and atmospheric control your project demands.

Ready to achieve superior sintering results? Contact our experts today to discuss your custom furnace needs.

Visual Guide

References

- František Nový, Miloš Mičian. The Influence of Induction Hardening, Nitriding and Boronising on the Mechanical Properties of Conventional and Sintered Steels. DOI: 10.3390/coatings14121602

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of using flowing nitrogen during annealing? Protect Music Wire Integrity

- Why is a uniform atmosphere important in carburizing workpieces? Ensure Consistent Hardness and Prevent Failures

- How does a thermal oxidation furnace facilitate the phase transformation of metallic vanadium? Learn V2O5 Optimization

- What safety features are incorporated into experimental box type atmosphere furnaces? Essential Protections for Hazardous Gas and Heat

- How is a high-temperature resistance furnace used to evaluate TiN coatings? Ensure Reliability for Aerospace Parts

- What heating mechanisms are available for retort furnaces? Choose Electric or Gas for Optimal Performance

- What advantages does the box type annealing atmosphere furnace offer? Achieve Superior Heat Treatment Control

- What critical protective roles does argon serve for AA7150-Al2O3 composites? Ensure Purity & Density