In short, a uniform atmosphere is critical in carburizing because it ensures every surface of the workpiece absorbs carbon evenly. This uniformity is the only way to guarantee a consistent case hardness and depth, preventing soft spots, brittleness, and premature component failure.

The core issue is predictability. Carburizing is a precise engineering process, not an art. An inconsistent atmosphere introduces variables that undermine the entire goal, leading to unreliable parts and costly rework. Uniformity is the foundation of quality control in heat treatment.

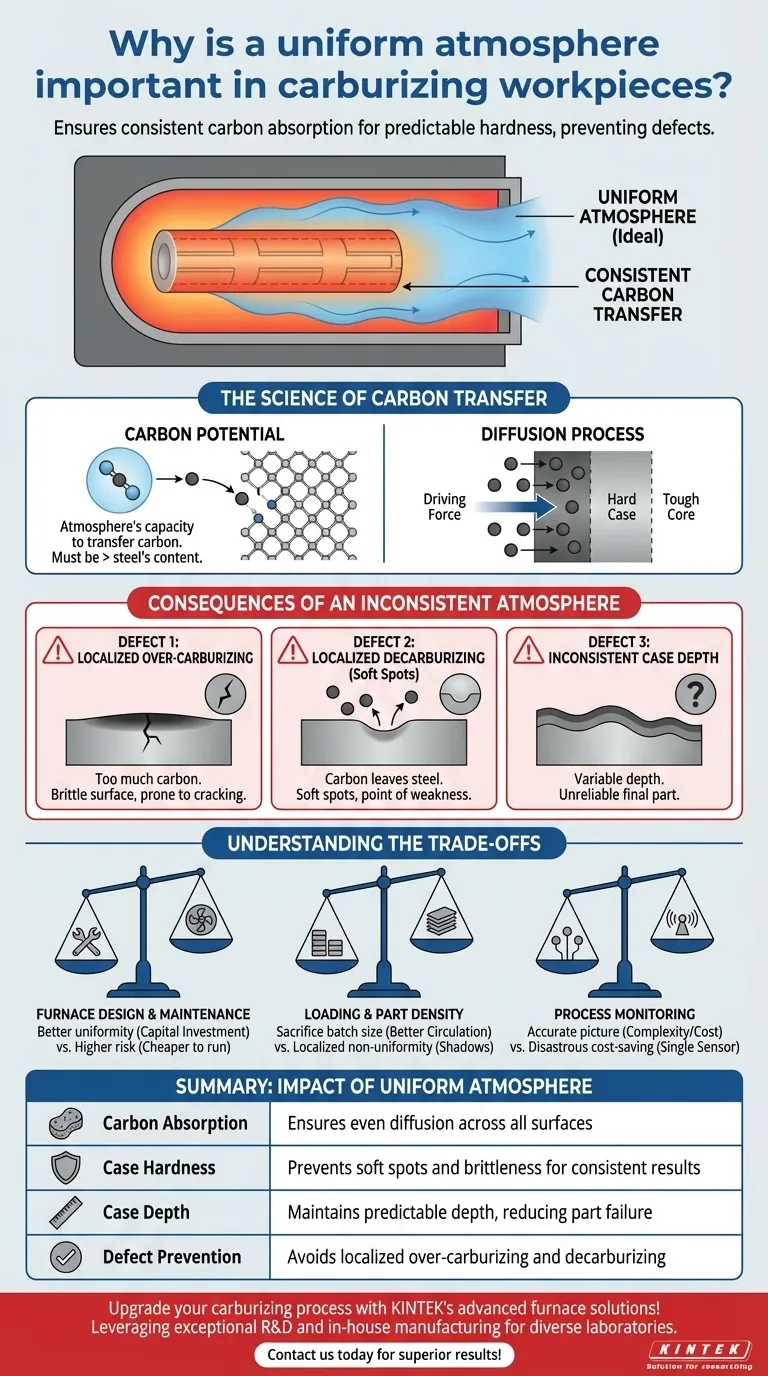

The Science of Carbon Transfer

Carburizing is a diffusion process designed to create a hard, wear-resistant surface (the "case") on a component while maintaining a softer, tougher interior (the "core").

The Role of Carbon Potential

The furnace atmosphere contains carbon-rich gases. The carbon potential of this atmosphere is its capacity to transfer carbon atoms to the surface of the steel.

For the process to work, the atmosphere's carbon potential must be higher than the carbon content of the steel. This difference drives carbon atoms to diffuse into the part's surface.

How Atmosphere Becomes Non-Uniform

An ideal, uniform atmosphere has the same carbon potential at every point within the furnace. In reality, factors like poor gas circulation, furnace leaks, or improper gas composition can create localized zones with different carbon potentials.

The Consequences of an Inconsistent Atmosphere

When the atmosphere is not uniform, different areas of the workpiece are exposed to different conditions, leading to critical defects.

Defect 1: Localized Over-Carburizing

If one area of the furnace has an excessively high carbon potential, that section of the workpiece will absorb too much carbon. This creates an overly hard, brittle surface prone to cracking under stress.

Defect 2: Localized Decarburizing (Soft Spots)

Conversely, if a section of the atmosphere has a lower carbon potential than the steel itself, the diffusion process reverses. Carbon atoms will actually leave the steel and enter the atmosphere.

This creates "soft spots" on the surface, which completely defeats the purpose of carburizing and creates a point of weakness.

Defect 3: Inconsistent Case Depth

The result of these inconsistencies is a case depth that varies across the component. The final part will not have the predictable, homogenous hardened layer required for its design specifications, making it unreliable in its final application.

Understanding the Trade-offs

Achieving a perfectly uniform atmosphere is a primary goal, but it involves balancing cost, time, and equipment capabilities.

Furnace Design and Maintenance

Modern furnaces with powerful circulation fans and tight seals provide better uniformity but represent a higher capital investment. Older or poorly maintained furnaces are cheaper to run but carry a much higher risk of producing non-conforming parts.

Loading and Part Density

Packing a furnace too tightly can create "shadows" that block gas flow, leading to localized non-uniformity. Sacrificing batch size for better gas circulation is a common trade-off to ensure higher quality and fewer rejections.

Process Monitoring

Relying on a single sensor to measure the entire furnace atmosphere is a cost-saving measure that can be disastrous. Using multiple sensors provides a more accurate picture but increases complexity and cost.

How to Apply This to Your Process

Your approach to atmospheric control should align directly with your operational goals.

- If your primary focus is maximum part quality and reliability: You must invest in robust furnace monitoring with multiple sensors and a rigorous maintenance schedule to ensure gas-tightness and circulation.

- If your primary focus is process efficiency and minimizing scrap: Standardizing furnace loading patterns and validating gas flow is essential to prevent the high cost of rework or rejected batches.

- If your primary focus is root cause analysis of failures: An inconsistent atmosphere should be one of your first suspects when investigating issues like cracking, distortion, or inconsistent hardness readings.

Ultimately, controlling the atmosphere is the most critical variable for controlling the outcome of your carburizing process.

Summary Table:

| Aspect | Impact of Uniform Atmosphere |

|---|---|

| Carbon Absorption | Ensures even carbon diffusion across all surfaces |

| Case Hardness | Prevents soft spots and brittleness for consistent results |

| Case Depth | Maintains predictable depth, reducing part failure |

| Defect Prevention | Avoids localized over-carburizing and decarburizing |

Upgrade your carburizing process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing quality control and reducing defects. Contact us today to discuss how we can optimize your heat treatment for superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing