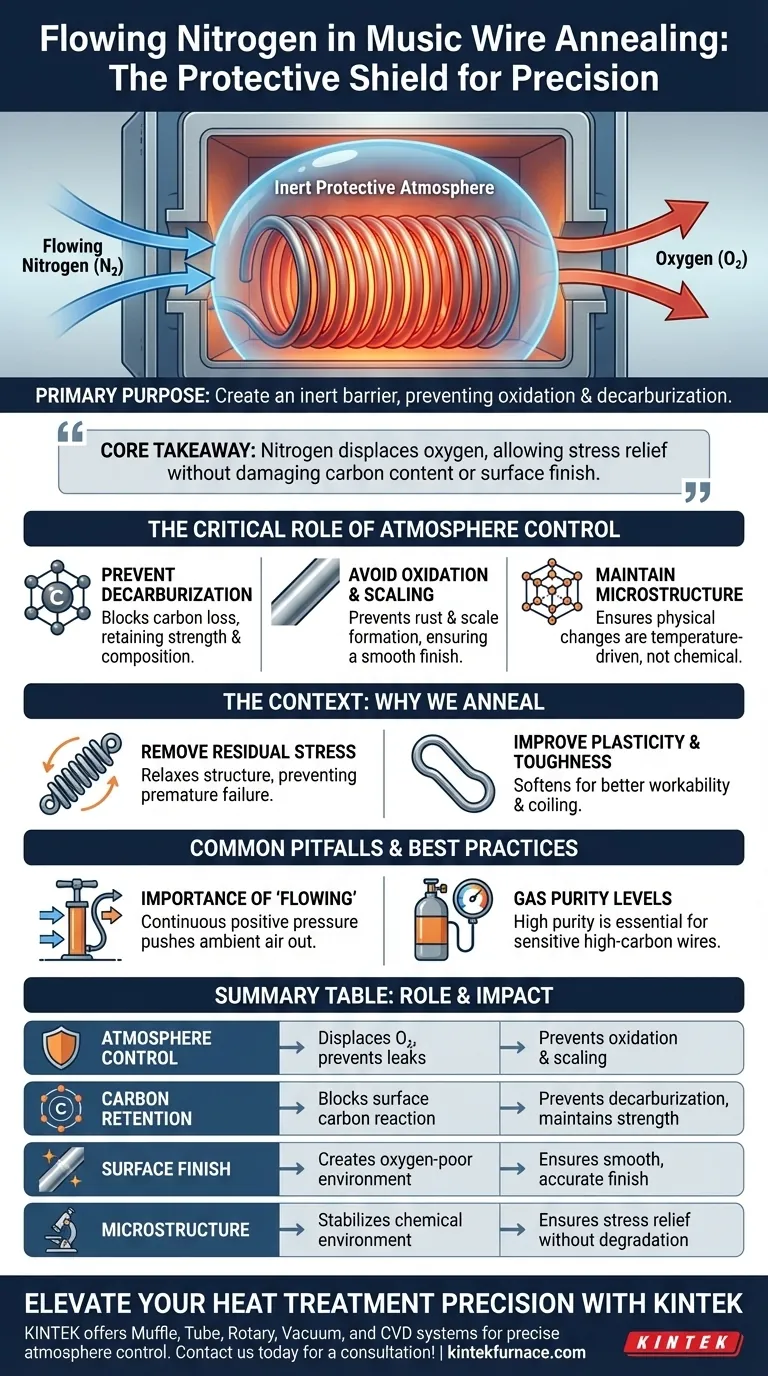

The primary purpose of using flowing nitrogen is to create an inert protective atmosphere around the music wire during high-temperature annealing. This gas barrier prevents the high-carbon steel from reacting with environmental oxygen, specifically shielding the material against oxidation and decarburization to maintain its structural and surface integrity.

Core Takeaway: Nitrogen acts as a shield during heat treatment. By displacing oxygen, it allows the annealing process to soften the wire and relieve stress without stripping away the carbon that gives the wire its strength or damaging the surface finish.

The Critical Role of Atmosphere Control

Preventing Decarburization

Music wire derives its exceptional strength and spring properties from its high carbon content. At elevated annealing temperatures, carbon atoms on the surface of the wire become volatile and interact with oxygen.

Without a protective gas, carbon is stripped from the steel (decarburization). Flowing nitrogen blocks this reaction, ensuring the wire retains the precise chemical composition required for its performance.

Avoiding Oxidation and Scaling

High temperatures accelerate the reaction between steel and oxygen. This results in the formation of scale (oxides) on the wire's exterior.

Nitrogen creates an oxygen-poor environment that prevents this corrosion. This preserves the wire's surface integrity, ensuring it remains smooth and dimensionally accurate.

Maintaining Microstructural Stability

The goal of annealing is to alter the internal structure of the metal beneficially. Uncontrolled chemical reactions at the surface can alter the underlying microstructure in unpredictable ways.

By maintaining an inert atmosphere, you ensure that the physical changes in the wire are driven solely by temperature and time, not by chemical degradation.

The Context: Why We Anneal Music Wire

Removing Residual Stress

As noted in broader metallurgical contexts, the mechanical processing of wire (such as drawing or winding) introduces internal tension. If left untreated, this residual stress can lead to premature failure.

Annealing relaxes the material structure. Nitrogen ensures this stress relief happens without compromising the material's surface.

Improving Plasticity and Toughness

Annealing is fundamentally a softening process. It reduces the wire's hardness slightly to improve its plasticity (ability to deform without breaking) and toughness.

This homogenization makes the wire more workable for subsequent manufacturing steps, such as coiling into springs.

Common Pitfalls and Trade-offs

The Importance of "Flowing" Gas

It is not enough to simply fill the furnace with nitrogen; the gas must be flowing. A static atmosphere allows oxygen to seep in through small leaks or furnace openings.

A continuous flow creates positive pressure inside the chamber. This actively pushes ambient air out, ensuring the protective barrier remains intact throughout the cycle.

Gas Purity Levels

Not all nitrogen supplies are equal. Standard industrial nitrogen may contain trace amounts of moisture or oxygen.

For extremely sensitive high-carbon wires, these impurities can still cause minor decarburization. You must verify that the purity of your nitrogen source matches the sensitivity of your material.

Making the Right Choice for Your Goal

To maximize the effectiveness of your heat treatment process, consider your specific objectives:

- If your primary focus is Surface Finish: Ensure a consistent, positive flow rate of nitrogen to prevent even minor oxidation or scaling.

- If your primary focus is Mechanical Strength: Prioritize high-purity nitrogen to strictly prevent decarburization, which weakens the outer layer of the wire.

Using flowing nitrogen transforms annealing from a destructive risk into a controlled, precision process.

Summary Table:

| Factor | Role of Flowing Nitrogen | Impact on Music Wire |

|---|---|---|

| Atmosphere Control | Displaces oxygen and prevents leaks | Prevents oxidation and surface scaling |

| Carbon Retention | Blocks carbon atoms from reacting at surface | Prevents decarburization to maintain strength |

| Surface Finish | Creates an inert, oxygen-poor environment | Ensures a smooth and dimensionally accurate finish |

| Microstructure | Stabilizes chemical environment during heating | Ensures stress relief without material degradation |

Elevate Your Heat Treatment Precision with KINTEK

Maximize the performance of your high-carbon steel and music wire with KINTEK’s advanced laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to provide the precise atmosphere control and positive pressure flow required to eliminate decarburization and oxidation. Whether you need a standard setup or a fully customizable system for unique lab needs, our high-temperature furnaces ensure your materials retain their structural and surface integrity.

Ready to optimize your annealing process? Contact KINTEK today for a consultation!

Visual Guide

References

- Xinru Jia, Jinhua Lu. Influence of Microstructure on Music Properties of SWP-B Music Steel Wire Under Different Annealing Treatments. DOI: 10.3390/ma18020440

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the technical advantages of using an electric furnace and clay graphite crucible for melting Al-Si-Cu-Mg alloys?

- How does atmosphere control affect homogenization annealing of low alloy steel? Achieve Precise Chemical Integrity

- What are the commonly used inert gases in atmosphere furnaces? Optimize Your Heat Treatment Process

- How is a controlled atmosphere furnace used in material research? Achieve Precise Material Synthesis and Heat Treatment

- Can atmosphere furnaces be customized for specific applications? Unlock Precision for Your Unique Processes

- How does the atmosphere differ between tube furnaces and box furnaces? Optimize Your Heat Treatment Process

- What protective function does furnace atmosphere provide? Essential for Preventing Oxidation and Decarburization

- What industries commonly use argon for heat treatment? Essential for Aerospace and High-Performance Alloys