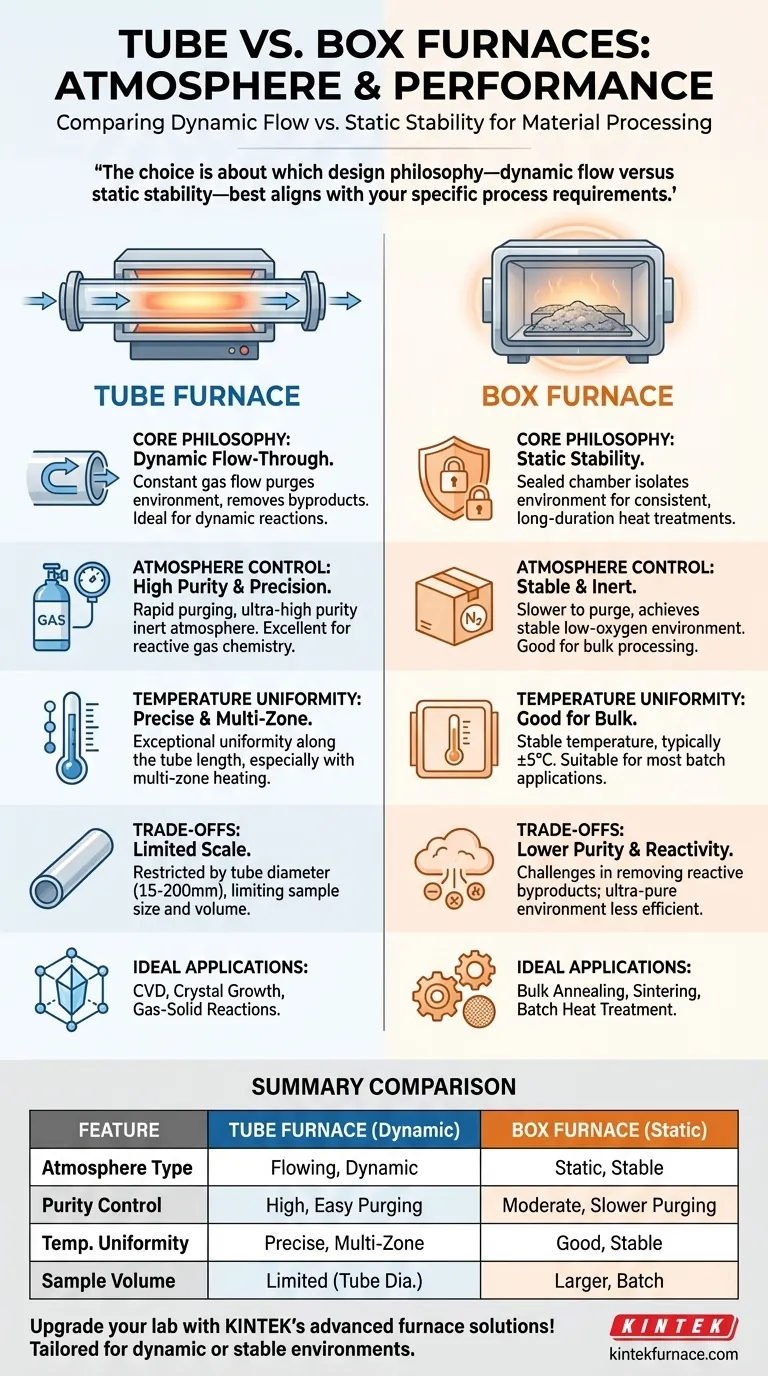

At their core, tube and box furnaces differ fundamentally in how they contain and manage their internal atmosphere. A tube furnace creates a controlled, often flowing atmosphere within a narrow, cylindrical tube, while a box furnace provides a more stable, static atmosphere within a larger, sealed chamber. This structural difference dictates their suitability for different material processing applications.

The choice between a tube and box furnace is not about which is superior, but which design philosophy—dynamic flow versus static stability—best aligns with your specific process requirements for atmospheric purity, temperature uniformity, and sample volume.

The Fundamental Design Difference

The physical construction of each furnace type is the primary driver of its atmospheric characteristics. They are built to solve different problems.

Tube Furnace: A Controlled Flow-Through System

Tube furnaces are designed around a long, cylindrical tube through which materials are heated. This tube can be oriented horizontally or vertically.

The small, contained volume of the tube makes it exceptionally well-suited for creating a specific atmosphere. Gases can be flowed through the tube, constantly purging the environment and carrying away any byproducts from the reaction.

Box Furnace: A Stable, Sealed Chamber

A box furnace, as its name implies, is a larger chamber designed to heat materials in batches. Once sealed, the internal environment is isolated from the outside.

The atmosphere inside is generally static. A specific gas (like nitrogen or argon) can be introduced to create an inert environment, but it is not typically circulated with the same dynamism as in a tube furnace.

Comparing Atmosphere Control and Purity

How you control the atmosphere is critical for processes like annealing, sintering, or growing crystals. The two furnace types offer different levels of precision.

Achieving an Inert Atmosphere

Tube furnaces excel at creating and maintaining a high-purity inert atmosphere. Their small diameter and constant gas flow make it easy to purge oxygen and other contaminants quickly and efficiently.

While box furnaces offer gas-sealed options, their larger internal volume requires more time and gas to achieve a comparable level of atmospheric purity. They are ideal for processes where a stable, low-oxygen environment is sufficient, but not necessarily one with ultra-high purity.

Atmosphere Circulation vs. Stability

The circulated atmosphere in a tube furnace is key for processes where the material surface must be consistently exposed to a specific gas. This is vital for chemical vapor deposition (CVD) or reactions that depend on gas-solid interaction.

The stable atmosphere of a box furnace is advantageous for bulk processing or for samples that could be disturbed by gas flow. It ensures a consistent environment for the duration of a long heat treatment cycle.

The Connection to Temperature Uniformity

Atmospheric control is intrinsically linked to temperature control. The way a furnace manages its atmosphere directly impacts how uniformly it can heat a sample.

Precision in Tube Furnaces

Tube furnaces generally offer more precise temperature control and faster heat-up times. Their compact nature and, in advanced models, the use of multiple heating zones (e.g., three-zone furnaces) allow for exceptional temperature uniformity along the length of the tube. This can be critical for growing uniform crystals or annealing long components.

Consistency in Box Furnaces

Box furnaces provide good temperature stability, often with an accuracy of around ±5°C. While less precise than a multi-zone tube furnace, this is perfectly suitable for many bulk applications. Some advanced atmosphere furnaces may include gas circulation fans specifically to improve temperature uniformity within the larger chamber.

Understanding the Trade-offs

Choosing the right furnace requires acknowledging the inherent limitations of each design.

Tube Furnace Limitations: Scale and Throughput

The primary trade-off for a tube furnace's precision is scale. The narrow diameter of the tube, typically ranging from 15 mm to 200 mm, limits the size and volume of the material you can process at one time.

Box Furnace Limitations: Purity and Reactivity

The main compromise with a box furnace is atmospheric purity and reactivity. The large, static volume can make it challenging to remove reactive gaseous byproducts generated during a process, and achieving an ultra-pure environment is less efficient than in a tube furnace.

Making the Right Choice for Your Process

Your final decision should be guided by the most critical variable in your experiment or production run.

- If your primary focus is high-purity processing or reactive gas chemistry: A tube furnace is the superior choice due to its excellent atmospheric purging and control.

- If your primary focus is batch processing of larger or multiple samples: A box furnace provides the necessary volume and stable environment for bulk heat treatment.

- If your primary focus is exceptional temperature uniformity over a specific length: A multi-zone tube furnace offers the most precise temperature gradient control available.

Ultimately, aligning the furnace's inherent atmospheric capabilities with your material's specific needs is the key to a successful outcome.

Summary Table:

| Feature | Tube Furnace | Box Furnace |

|---|---|---|

| Atmosphere Type | Flowing, dynamic | Static, stable |

| Purity Control | High, easy purging | Moderate, slower purging |

| Temperature Uniformity | Precise, multi-zone options | Good, stable for bulk |

| Sample Volume | Limited by tube diameter | Larger, batch processing |

| Ideal Applications | CVD, gas-solid reactions | Bulk annealing, sintering |

Upgrade your laboratory efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you require dynamic atmosphere control for high-purity processes or stable environments for bulk processing, KINTEK has the expertise to deliver. Contact us today to discuss how we can optimize your heat treatment workflows and achieve superior results!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control