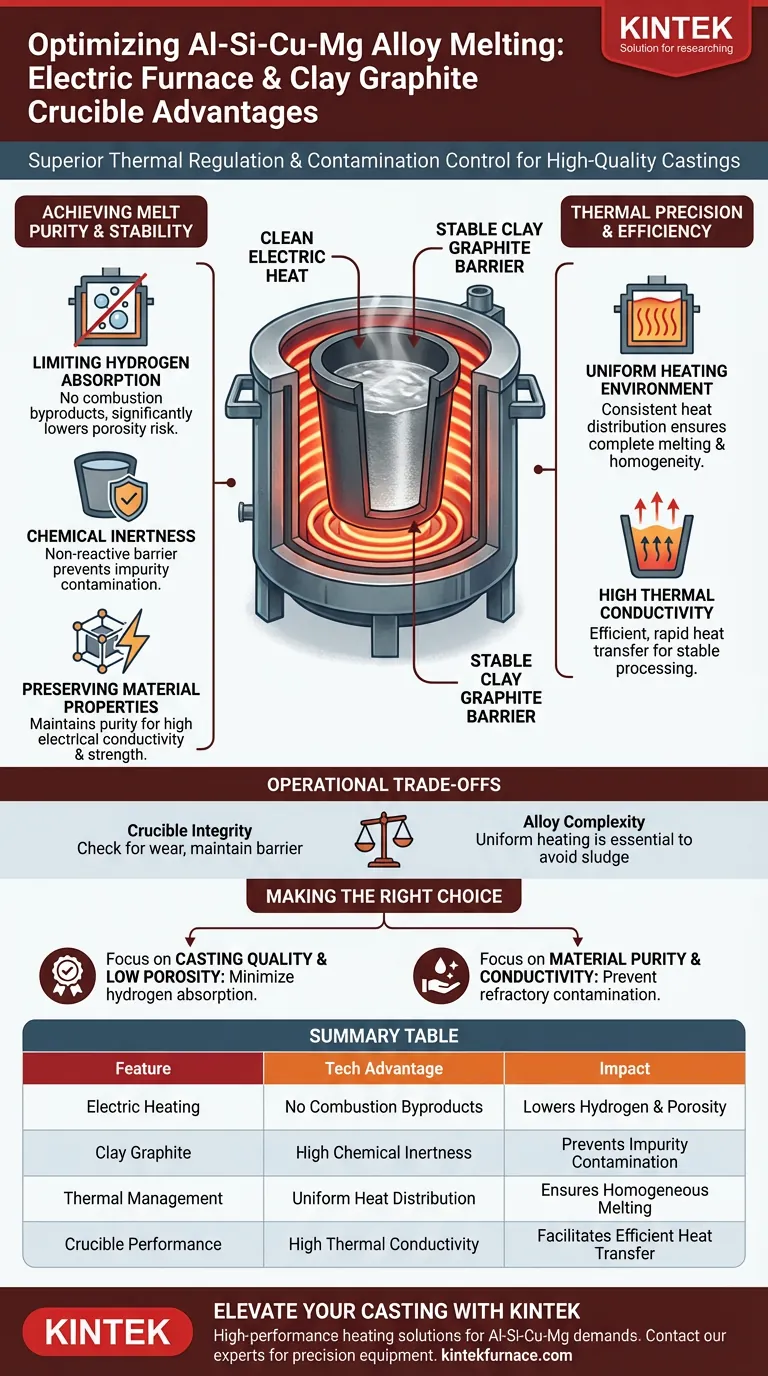

The combination of a precision-controlled industrial electric furnace and a clay graphite crucible offers superior thermal regulation and contamination control. For Al-Si-Cu-Mg alloys, this setup technically excels by establishing a uniform heating environment that ensures complete melting of all alloy components while drastically minimizing hydrogen absorption and chemical impurities.

Core Takeaway Achieving high-quality aluminum alloy castings requires isolating the melt from two primary enemies: inconsistent heat and chemical reactivity. By pairing the clean energy of electric heating with the chemical inertness of clay graphite, you create a stable environment that preserves the alloy’s purity and mechanical properties.

Achieving Melt Purity and Stability

Limiting Hydrogen Absorption

One of the most critical technical advantages of using an electric furnace is the reduction of gas uptake.

Unlike fuel-fired furnaces, electric furnaces do not generate combustion byproducts. This significantly lowers the risk of hydrogen absorption into the melt, which is a common cause of porosity and defects in solidified aluminum alloys.

Chemical Inertness

The clay graphite crucible acts as a non-reactive barrier between the heat source and the metal.

Because of its high chemical stability, the crucible effectively contains the molten aluminum without reacting with it. This prevents the introduction of foreign impurities that often result from crucible degradation in less stable refractory materials.

Preserving Material Properties

By preventing chemical reactions and impurity contamination, this setup protects the intrinsic properties of the Al-Si-Cu-Mg alloy.

Maintaining a pure melt is essential for ensuring the final material meets its performance specifications, such as electrical conductivity and mechanical strength.

Thermal Precision and Efficiency

Uniform Heating Environment

Al-Si-Cu-Mg alloys contain multiple elements with varying melting points, requiring precise thermal management.

The electric furnace provides a consistent, controlled heat distribution. This ensures the complete melting of all alloy components, preventing segregation and ensuring a homogeneous liquid structure.

High Thermal Conductivity

Clay graphite crucibles are selected not just for protection, but for performance.

They possess high thermal conductivity, which allows for efficient heat transfer from the furnace coils to the melt. This facilitates rapid, even heating while maintaining the high thermal stability required at melting temperatures (typically around 750°C).

Understanding the Operational Trade-offs

The Necessity of Precision

While this setup offers maximum quality, it relies heavily on the integrity of the equipment.

The benefits of chemical inertness are only maintained as long as the crucible surface remains intact. Operators must monitor the crucible for wear, as any degradation can compromise the barrier and lead to the very contamination the system is designed to avoid.

Complexity of Alloy Management

The uniform heating provided by this setup is a requirement, not just a luxury, for complex alloys like Al-Si-Cu-Mg.

Failing to achieve this uniformity leads to incomplete melting or "sludge" formation. Therefore, the technical advantage here is also a strict operational constraint: this specific equipment combination is often necessary to avoid the inherent processing difficulties of complex multi-component alloys.

Making the Right Choice for Your Goal

When selecting melting equipment for aluminum alloys, align your choice with your quality requirements.

- If your primary focus is Casting Quality and Low Porosity: Prioritize this electric furnace and graphite crucible setup to minimize hydrogen absorption and gas-related defects.

- If your primary focus is Material Purity and Conductivity: Rely on the chemical inertness of the clay graphite crucible to prevent refractory contamination that degrades electrical performance.

Ultimately, this specific equipment combination transforms the melting process from a variable-heavy risk into a controlled, high-purity baseline for superior alloy production.

Summary Table:

| Feature | Technical Advantage | Impact on Al-Si-Cu-Mg Alloy |

|---|---|---|

| Electric Heating | No combustion byproducts | Dramatically lowers hydrogen absorption and porosity |

| Clay Graphite Material | High chemical inertness | Prevents impurity contamination and preserves conductivity |

| Thermal Management | Uniform heat distribution | Ensures homogeneous melting of multi-element components |

| Crucible Performance | High thermal conductivity | Facilitates rapid, efficient, and stable heat transfer |

Elevate Your Alloy Casting Precision with KINTEK

Don’t let gas porosity or chemical impurities compromise your material performance. KINTEK provides high-performance heating solutions designed for the rigorous demands of Al-Si-Cu-Mg alloy production.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, CVD systems, and other lab high-temp furnaces, all customizable for your unique research or production needs. Our precision equipment ensures the thermal stability and melt purity required for superior mechanical and electrical properties.

Ready to optimize your melting process? Contact our technical experts today to find the perfect furnace and crucible configuration for your laboratory or industrial application.

Visual Guide

References

- Influence of Geometrical Design on Defect Formation of Commercial Al-Si-Cu-Mg Alloy Fabricated by High-Pressure Diecasting: Structural Observation and Simulation Validation. DOI: 10.3390/met15010042

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What related term is mentioned in connection with controlled atmosphere furnaces? Discover Sealed Quench for Superior Heat Treatment

- What are the thermal insulation properties of argon in furnace applications? Unlock Material Purity and Efficiency

- What function does a flow-gas furnace serve in iron ore reduction? Mastering Lab Gas Delivery and Thermal Sync

- What is the purpose of steam atmosphere in furnace applications? Enhance Metal Durability with Controlled Oxidation

- What critical protective roles does argon serve for AA7150-Al2O3 composites? Ensure Purity & Density

- How does a retort furnace control the atmosphere? Master Precise Heat Treatment for Superior Results

- How does a laboratory electric furnace support the process of evaluating the light-off temperature of Pd/Al2O3 catalysts?

- What are the features of continuous annealing furnaces? Boost High-Volume Production Efficiency