At their core, continuous annealing furnaces are defined by features engineered for high-volume, uninterrupted production. Key characteristics include heavy-duty construction, energy-efficient insulation using a combination of fiber and brick, and advanced systems for precise, real-time temperature and atmosphere control. These furnaces are designed for minimal maintenance and are optimized to process materials like wire, rod, strip, and tubes consistently and safely.

The primary advantage of a continuous annealing furnace isn't just one feature, but how all its components work in concert. They are designed as an integrated system to deliver maximum production efficiency, repeatable quality, and lower operating costs for high-volume manufacturing.

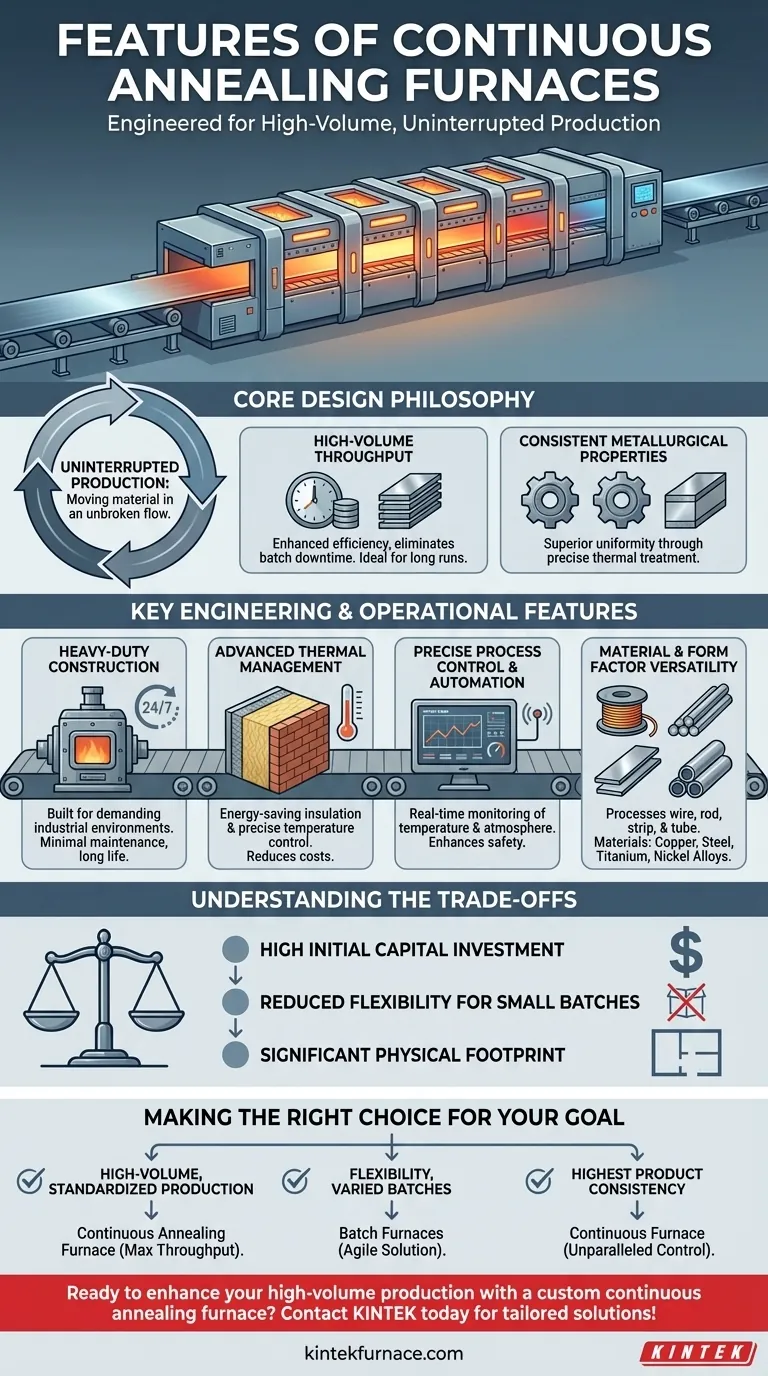

The Core Design Philosophy: Uninterrupted Production

Continuous annealing furnaces are fundamentally different from batch furnaces. Their design is centered on moving material through various heating and cooling zones in an unbroken flow, which dictates their primary characteristics and benefits.

High-Volume Throughput

The most significant advantage is enhanced production efficiency. By continuously processing material, these furnaces eliminate the downtime associated with loading and unloading individual batches.

This design makes them exceptionally well-suited for high-volume manufacturing environments where long runs of standardized products are common.

Consistent Metallurgical Properties

Material moves through precisely controlled temperature zones at a constant speed. This ensures that every section of the product receives the exact same thermal treatment.

The result is superior uniformity and consistency in the final mechanical and metallurgical properties, which is difficult to achieve in batch processing.

Key Engineering and Operational Features

The overall design philosophy is supported by specific engineering choices that define the furnace's performance, cost-effectiveness, and safety.

Heavy-Duty Construction

These furnaces are built for 24/7 operation in demanding industrial environments. Their robust, heavy-duty construction ensures a long service life and high reliability.

This durable design also leads to minimal maintenance requirements, maximizing uptime and reducing long-term operational costs.

Advanced Thermal Management

A key feature is an energy-saving insulation system, often combining lightweight ceramic fiber with durable insulating brick. This hybrid approach minimizes thermal loss, directly reducing energy consumption and operating costs.

This efficient insulation works alongside precise temperature control systems that maintain stable and accurate temperatures within each zone of the furnace.

Precise Process Control and Automation

Modern continuous furnaces utilize advanced control systems to monitor and regulate critical parameters like temperature and atmosphere in real-time.

These systems, particularly in continuous vacuum furnaces, greatly enhance operational safety. They can automatically detect and respond to any process anomalies, ensuring the protection of both the equipment and the product.

Material and Form Factor Versatility

While optimized for long runs, these furnaces are versatile. They are engineered to process a wide range of product forms, including wire, rod, strand, strip, and tube products.

They can effectively anneal numerous metals, from copper and stainless steel to more specialized materials like titanium, nickel alloys, and refractory metals.

Understanding the Trade-offs

While powerful, continuous annealing furnaces are not the universal solution. Their specialized design comes with important considerations.

High Initial Capital Investment

The complexity, size, and advanced automation of a continuous line mean the initial capital cost is significantly higher than that of a batch furnace system.

Reduced Flexibility for Small Batches

These systems are optimized for long, continuous runs of a single product specification. They are not efficient for high-mix, low-volume production, as changing the setup for a different product can be time-consuming.

Significant Physical Footprint

A continuous annealing line is a large piece of equipment that requires a substantial amount of dedicated floor space within a facility.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on your specific production needs and business objectives.

- If your primary focus is high-volume, standardized production: A continuous annealing furnace is the superior choice for maximizing throughput and minimizing per-unit cost.

- If your primary focus is flexibility for varied, small-to-medium batches: A series of batch furnaces will likely provide a more agile and cost-effective solution.

- If your primary focus is achieving the highest possible product consistency: The automated and stable process of a continuous furnace offers unparalleled control over metallurgical outcomes.

Ultimately, understanding these core features and trade-offs empowers you to align your equipment investment with your operational strategy.

Summary Table:

| Feature | Description |

|---|---|

| High-Volume Throughput | Enables uninterrupted production for long runs, maximizing efficiency and reducing downtime. |

| Consistent Metallurgical Properties | Provides uniform heating and cooling for repeatable quality in mechanical properties. |

| Heavy-Duty Construction | Built for 24/7 operation with minimal maintenance, ensuring reliability and long service life. |

| Advanced Thermal Management | Uses energy-saving insulation and precise temperature control to reduce energy costs. |

| Precise Process Control | Features real-time monitoring and automation for safety and accurate atmosphere regulation. |

| Material Versatility | Processes various forms like wire, rod, strip, and tubes, and metals including copper and stainless steel. |

| Trade-offs | High initial investment, reduced flexibility for small batches, and large physical footprint. |

Ready to enhance your high-volume production with a custom continuous annealing furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how our tailored solutions can boost your efficiency and reduce operating costs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing