A key related term for controlled atmosphere furnaces is the sealed quench furnace. This specific type of furnace integrates the quenching (rapid cooling) stage into the same controlled environment as the heating stage, ensuring the material's surface properties are maintained throughout the entire heat treatment cycle.

While many terms describe different types of controlled atmosphere furnaces, "sealed quench" is uniquely important because it defines a complete, integrated process. It highlights that successful heat treatment depends not just on controlled heating, but equally on controlled cooling within that same protective environment.

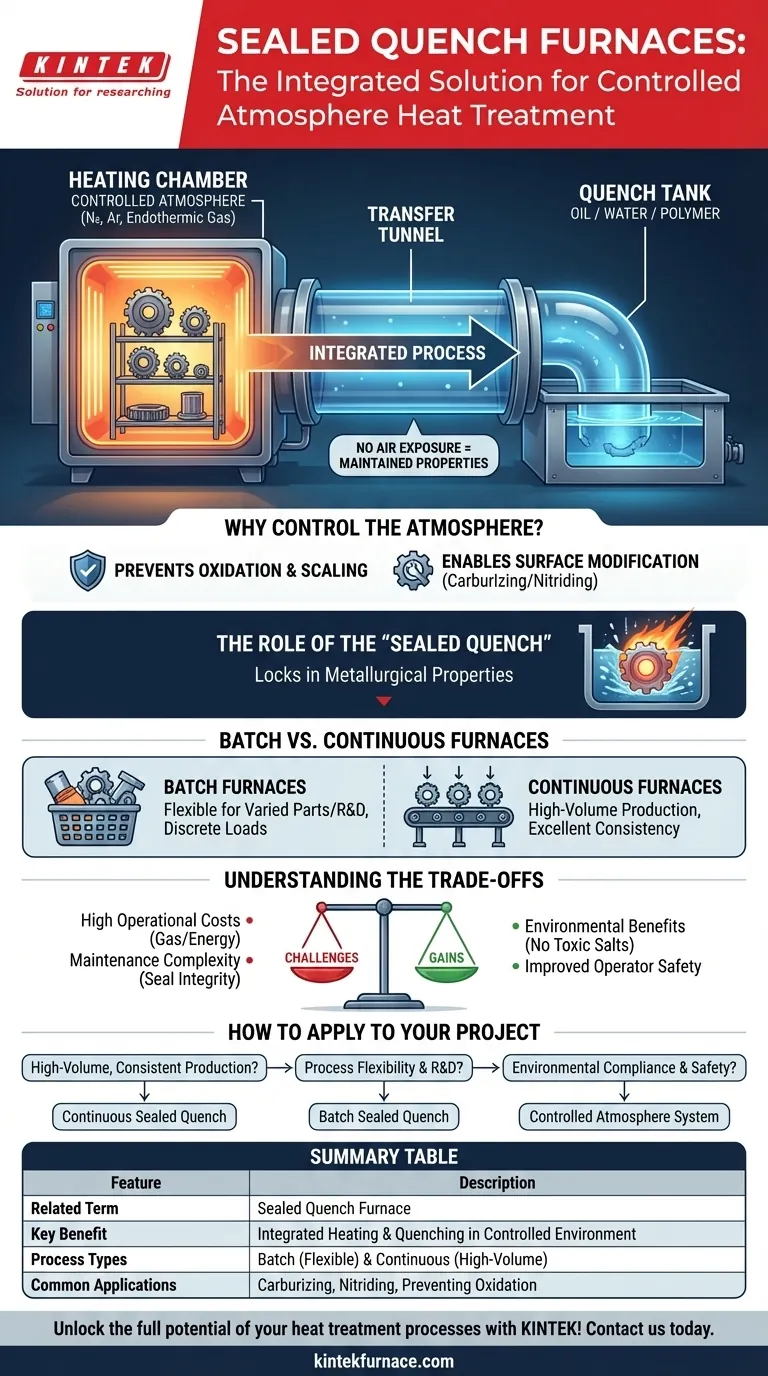

The Core Concept: An Integrated Treatment Environment

A controlled atmosphere furnace is designed to do more than simply heat a material. Its primary function is to precisely manage the chemical environment surrounding a part to achieve specific surface characteristics.

Why Control the Atmosphere?

The atmosphere inside the furnace is carefully regulated using specific gases (like nitrogen, argon, or endothermic gas) to prevent undesirable chemical reactions. This control prevents oxidation and scaling that would otherwise occur when heating metals to high temperatures in air.

Furthermore, it allows for processes like carburizing or nitriding, where the surface chemistry of a part is intentionally altered by introducing elements like carbon or nitrogen to increase surface hardness and wear resistance.

The Role of the "Sealed Quench"

The benefits gained during controlled heating can be lost in seconds if the hot part is exposed to open air before it has cooled. A sealed quench furnace solves this problem.

It is an integrated system where the workpiece moves from the high-temperature heating chamber directly into an adjoining quench tank—typically containing oil, water, or polymer—without ever leaving the protective atmosphere. This ensures the metallurgical properties achieved in the heating phase are locked in.

Batch vs. Continuous Furnaces

Controlled atmosphere furnaces are broadly divided into two operational types, both of which can incorporate a sealed quench design.

-

Batch Furnaces: These systems process discrete loads or "batches" of parts. They are highly flexible and ideal for a wide variety of part sizes, shapes, and process requirements, including job-shop environments.

-

Continuous Furnaces: Designed for high-volume production, these furnaces move parts through different temperature zones on a conveyor. They offer excellent consistency and efficiency for a dedicated process but lack the flexibility of batch furnaces.

Understanding the Trade-offs

While powerful, this technology requires a clear understanding of its operational demands and costs. The decision to use a controlled atmosphere system involves balancing significant advantages against notable challenges.

High Operational Costs

The primary cost drivers are the continuous consumption of specialized inert or reactive gases and the high energy required to maintain elevated process temperatures. These costs can be substantial, particularly in continuous, large-scale operations.

Maintenance Complexity

The term "sealed" is critical. The integrity of the furnace's seals, doors, and transfer mechanisms is paramount. Any leak can compromise the atmosphere, ruin the workpiece, and create potential safety hazards. This demands a rigorous and preventative maintenance schedule.

Significant Environmental and Safety Gains

Despite the costs, these furnaces offer major environmental benefits over older methods. They eliminate the need for toxic cyanide salts used in traditional case hardening, preventing land contamination and simplifying waste disposal for a much safer and cleaner operating environment.

How to Apply This to Your Project

Choosing the right furnace technology depends entirely on your specific manufacturing or research goals.

- If your primary focus is high-volume, consistent production: A continuous sealed quench furnace is the industry standard for processes like carburizing.

- If your primary focus is process flexibility for varied parts or R&D: A batch-type sealed quench furnace offers the versatility needed for smaller lots and developing new treatment cycles.

- If your primary focus is environmental compliance and operator safety: A controlled atmosphere system is a far superior choice over traditional salt bath or pack carburizing methods.

Ultimately, selecting the right furnace means evaluating your entire process flow to ensure both the heating and cooling phases meet your material's precise requirements.

Summary Table:

| Feature | Description |

|---|---|

| Related Term | Sealed Quench Furnace |

| Key Benefit | Integrated heating and quenching in a controlled environment |

| Process Types | Batch (flexible) and Continuous (high-volume) |

| Common Applications | Carburizing, nitriding, preventing oxidation |

| Operational Considerations | High gas/energy costs, maintenance for seal integrity |

Unlock the full potential of your heat treatment processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in R&D or high-volume production, our sealed quench and controlled atmosphere furnaces ensure superior performance, safety, and efficiency. Contact us today to discuss how we can enhance your laboratory's capabilities and achieve your material science goals!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling