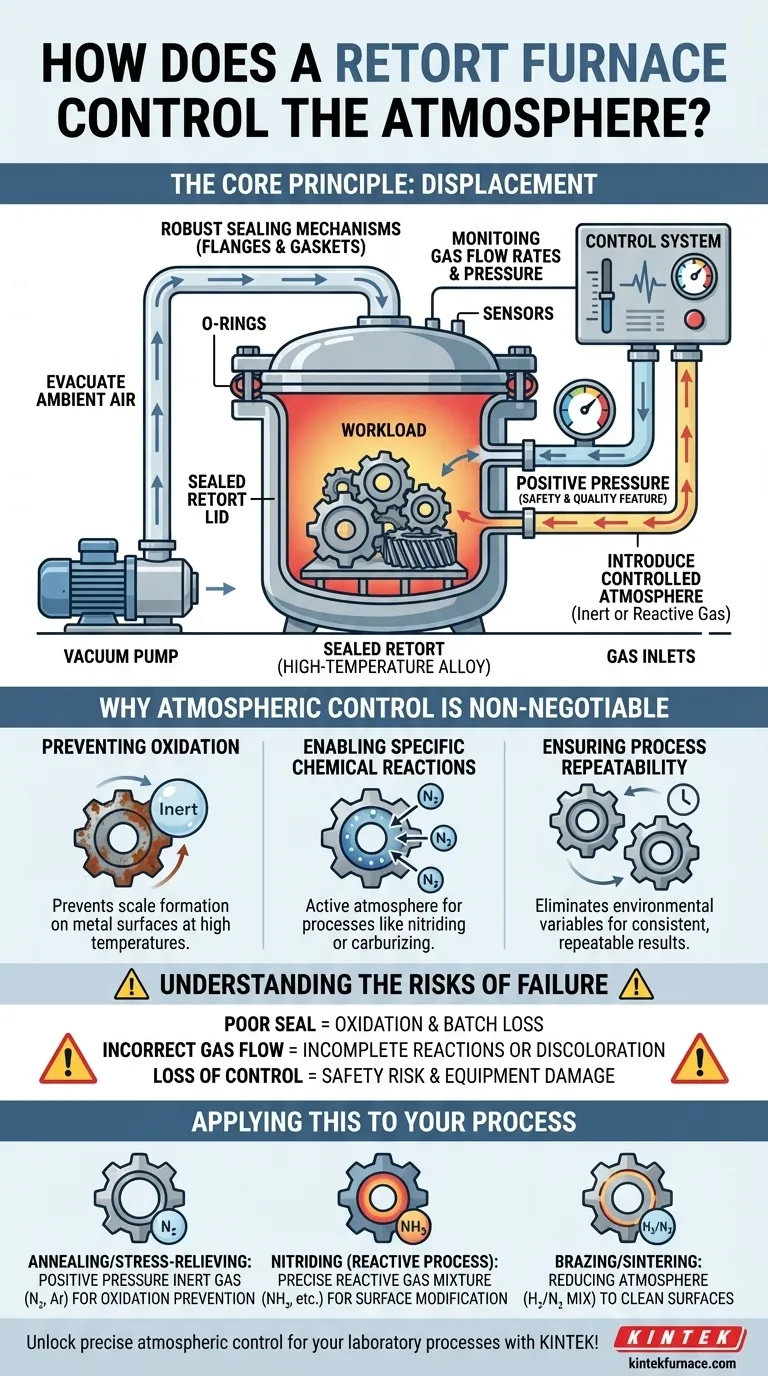

At its core, a retort furnace controls its atmosphere by creating a physically isolated, airtight chamber known as a retort. This sealed vessel allows for the complete removal of ambient air and its replacement with a precisely managed gas or a vacuum. This process of isolation and substitution is fundamental to preventing unwanted chemical reactions, such as oxidation, during high-temperature processing.

The essential principle is one of displacement. By first sealing the workload inside the retort, you can then purge the reactive air and introduce a specific, controlled environment—whether it's an inert gas, a reactive gas mixture, or a vacuum—that is required for a successful process.

The Anatomy of Atmospheric Control

Understanding how a retort furnace achieves such precise control requires looking at its key mechanical and system components. Each part plays a critical role in creating and maintaining the desired environment.

The Sealed Retort: The Core of Isolation

The central component is the retort itself, typically a cylindrical or box-shaped vessel made of high-temperature-resistant metal alloys. This retort acts as the sealed chamber where the material is placed.

To ensure it is airtight, the system relies on robust sealing mechanisms. These often include stainless steel flanges and high-temperature silicone rubber O-rings or other gaskets, which prevent both gas from leaking out and, more importantly, air from leaking in.

The Gas Management System: Purge and Fill

Atmospheric control is an active process managed by a dedicated gas system. This system has two primary functions.

First, it evacuates the ambient air from the sealed retort. This is often done with a vacuum pump, which removes the oxygen and nitrogen that would otherwise react with the parts at high temperatures.

Second, it introduces the desired atmosphere through gas inlets. This could be an inert gas like nitrogen or argon to prevent any reaction, or a specific reactive gas mixture (like hydrogen or ammonia) for processes such as nitriding or carburizing.

The Control System: Precision and Safety

The entire process is governed by an atmosphere control system. This system uses sensors to monitor pressure and gas composition within the retort.

It works in tandem with the temperature controller to manage gas flow rates, ensuring a slight positive pressure is maintained. This positive pressure is a key safety and quality feature, as it helps prevent any outside air from being drawn into the chamber if a microscopic leak were to exist.

Why Atmospheric Control is Non-Negotiable

Failing to properly control the furnace atmosphere isn't a minor issue; it can lead to complete process failure. The integrity of the final product depends entirely on maintaining the specified environment.

Preventing Oxidation and Contamination

The most common reason for atmospheric control is to prevent oxidation. At high temperatures, most metals will readily react with oxygen, forming a layer of scale on the surface that can ruin the part's finish, dimensions, and material properties.

Enabling Specific Chemical Reactions

For many heat-treatment processes, the atmosphere is not just protective but an active ingredient. Processes like carburizing (adding carbon) or nitriding (adding nitrogen) require specific gas compositions to achieve a desired change in the material's surface chemistry.

Ensuring Process Repeatability

A controlled atmosphere eliminates the variables of ambient humidity and air composition. This ensures that every part in a batch and every subsequent batch is processed under the exact same conditions, leading to highly consistent and repeatable results.

Understanding the Risks of Failure

An improperly controlled atmosphere is a direct path to rejected parts, wasted resources, and potential safety hazards.

The High Cost of a Poor Seal

The entire system's effectiveness hinges on the integrity of the retort's seal. Even a small leak can introduce enough oxygen to cause oxidation, compromising the quality of an entire batch and leading to significant financial and time loss.

The Impact of Incorrect Gas Flow

Simply filling the chamber with gas is not enough. An insufficient flow rate may fail to purge all contaminants or maintain the necessary positive pressure, allowing air to enter. This can cause discoloration, scaling, or incomplete chemical reactions on the material's surface.

Safety and Equipment Damage

In the worst-case scenarios, a loss of atmospheric control can be a safety risk. For example, introducing flammable gases like hydrogen into a chamber that is not properly purged of oxygen can create an explosive mixture. Furthermore, unwanted reactions can damage the furnace's internal components, including the retort itself.

Applying This to Your Process

The specific atmospheric control strategy you use depends entirely on your process goal.

- If your primary focus is simple annealing or stress-relieving: Your goal is to ensure a positive pressure of a high-purity inert gas, like nitrogen or argon, to prevent any surface oxidation during the thermal cycle.

- If your primary focus is a reactive process like nitriding: You must precisely control gas composition, flow rates, and temperature, as the atmosphere itself is an active ingredient in modifying the part's surface.

- If your primary focus is brazing or sintering: You need a reducing atmosphere, often a hydrogen/nitrogen mix, to clean surfaces and promote metallurgical bonding while preventing oxidation.

Mastering atmospheric control transforms your retort furnace from a simple oven into a precise materials processing tool.

Summary Table:

| Component/Function | Key Details |

|---|---|

| Sealed Retort | Airtight chamber made of high-temperature alloys with sealing mechanisms (e.g., O-rings) to isolate the workload. |

| Gas Management System | Evacuates ambient air and introduces controlled gases (e.g., inert or reactive) via inlets and vacuum pumps. |

| Control System | Monitors pressure and gas composition, maintains positive pressure for safety and consistency. |

| Primary Benefits | Prevents oxidation, enables specific reactions (e.g., carburizing), ensures repeatability and safety. |

Unlock precise atmospheric control for your laboratory processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Contact us today to enhance your heat treatment outcomes and ensure consistent, high-quality results!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance