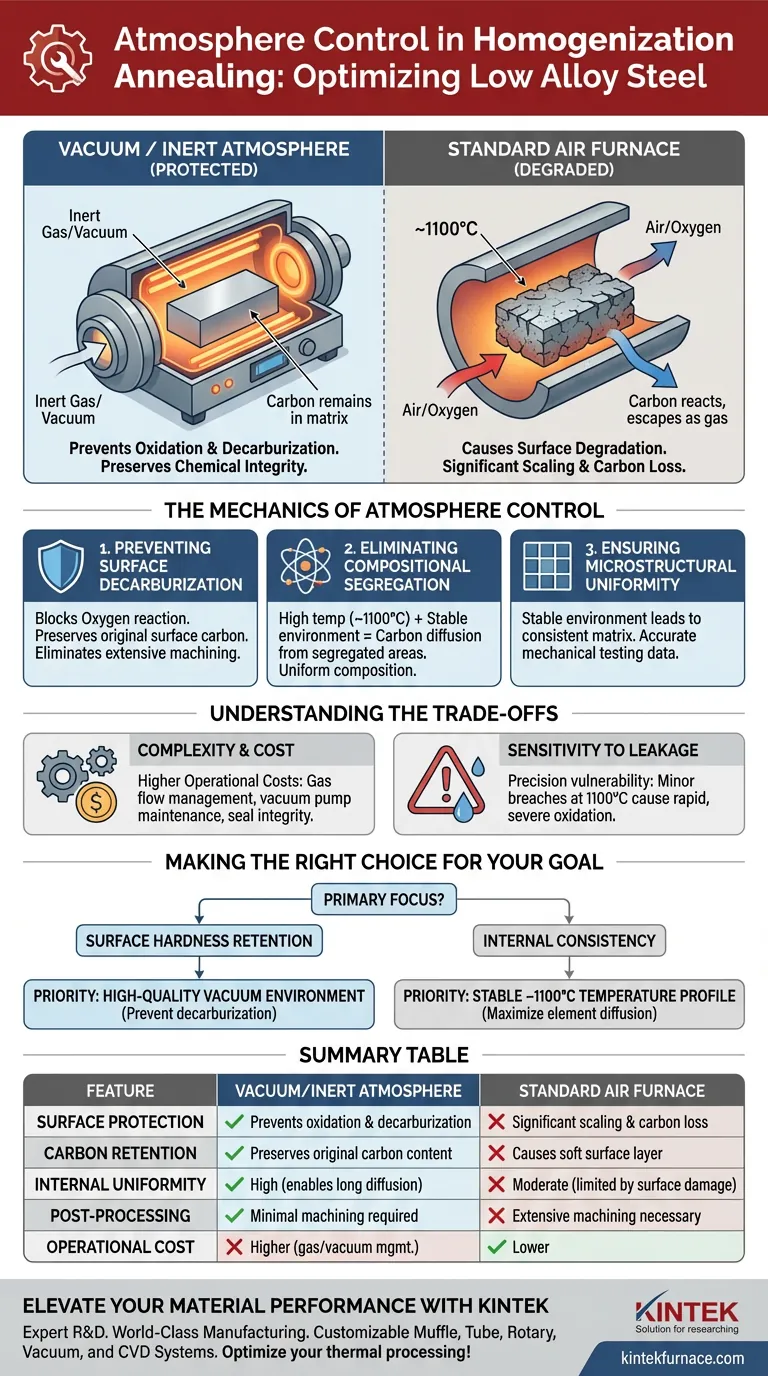

Atmosphere control determines the chemical integrity of low alloy steel during the homogenization annealing process. By utilizing a vacuum or inert environment within a tube or muffle furnace, you actively prevent surface oxidation and decarburization. This protection allows the material to undergo necessary microstructural changes without suffering the surface degradation typical of air-processed metals.

By maintaining a vacuum or inert atmosphere at temperatures around 1100°C, these furnaces ensure that carbon remains within the steel matrix rather than reacting with oxygen, resulting in a compositionally uniform material.

The Mechanics of Atmosphere Control

Preventing Surface Decarburization

In standard air furnaces, high temperatures cause carbon atoms on the steel's surface to react with oxygen, escaping as gas. This leaves a "decarburized" layer with poor mechanical properties.

Vacuum and inert atmospheres effectively block this reaction. They preserve the steel's original carbon content right up to the surface, eliminating the need for extensive post-process machining to remove damaged layers.

Eliminating Compositional Segregation

Low alloy steels often suffer from segregation, where carbon and other elements clump together rather than spreading evenly.

Under a controlled atmosphere, you can safely hold the steel at high temperatures (approx. 1100°C) for extended periods. This thermal environment provides the necessary activation energy for carbon atoms to diffuse from segregated areas back into the main matrix.

Ensuring Microstructural Uniformity

The ultimate goal of homogenization is consistency. By removing the variable of oxidation, the furnace creates a stable environment where diffusion is the dominant physical process.

This results in a uniform microstructure throughout the cross-section of the material. A consistent matrix ensures that subsequent mechanical testing yields accurate data regarding the steel's true properties, rather than its defects.

Understanding the Trade-offs

Process Complexity and Cost

While air annealing is simple, operating under vacuum or inert gas adds significant variables. You must manage gas flow rates, vacuum pump maintenance, and seal integrity, which increases operational costs.

Sensitivity to Leakage

The precision of this process is also its vulnerability. At 1100°C, even a minor breach in the vacuum seal or a contaminant in the inert gas supply can lead to rapid, severe oxidation, potentially ruining the entire batch.

Making the Right Choice for Your Goal

- If your primary focus is surface hardness retention: Prioritize a high-quality vacuum environment to prevent the loss of surface carbon (decarburization).

- If your primary focus is internal consistency: Ensure the furnace can maintain a stable 1100°C temperature profile to maximize the diffusion of segregated elements.

Atmosphere control transforms annealing from a simple heating process into a precision chemical preservation strategy, ensuring your low alloy steel performs exactly as designed.

Summary Table:

| Feature | Vacuum/Inert Atmosphere | Standard Air Furnace |

|---|---|---|

| Surface Protection | Prevents oxidation & decarburization | Significant scaling & carbon loss |

| Carbon Retention | Preserves original carbon content | Causes soft surface layer |

| Internal Uniformity | High (enables long diffusion times) | Moderate (limited by surface damage) |

| Post-Processing | Minimal machining required | Extensive machining necessary |

| Operational Cost | Higher (gas/vacuum management) | Lower |

Elevate Your Material Performance with KINTEK

Don't let oxidation compromise your alloy research or manufacturing. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our high-temperature lab furnaces are fully customizable to meet your specific homogenization and annealing requirements, ensuring your low alloy steels achieve perfect microstructural uniformity every time.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Guillaume Ah‐Lung, Johan Jacquemin. Effects of Melting/Casting and Thermal Treatment Surrounding Gas Phase Composition on the Properties of a Low-Alloyed Steel. DOI: 10.3390/met14121317

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why must a high-purity argon protective atmosphere be maintained during mechanical alloying? Ensure Peak Material Purity

- What are the main types of nitrogen-based furnace atmospheres? Optimize Your Heat Treatment Process

- How do atmosphere control systems contribute to furnace operation? Unlock Precision and Quality in Material Processing

- How do atmosphere furnaces improve material properties? Achieve Superior Material Performance with Precision Control

- What is the pressure range of an atmosphere box furnace under high-pressure conditions? Discover Custom Solutions for Your Lab

- How does a programmable high-temperature annealing furnace improve AZO thin films? Master Your Atmosphere Control

- How does the nitrogen-protected environment benefit biomass carbonization? Unlock High-Yield Pyrolysis Secrets

- What are the key advantages of a box type atmosphere furnace? Superior Control, Efficiency, and Versatility for Heat Treatment