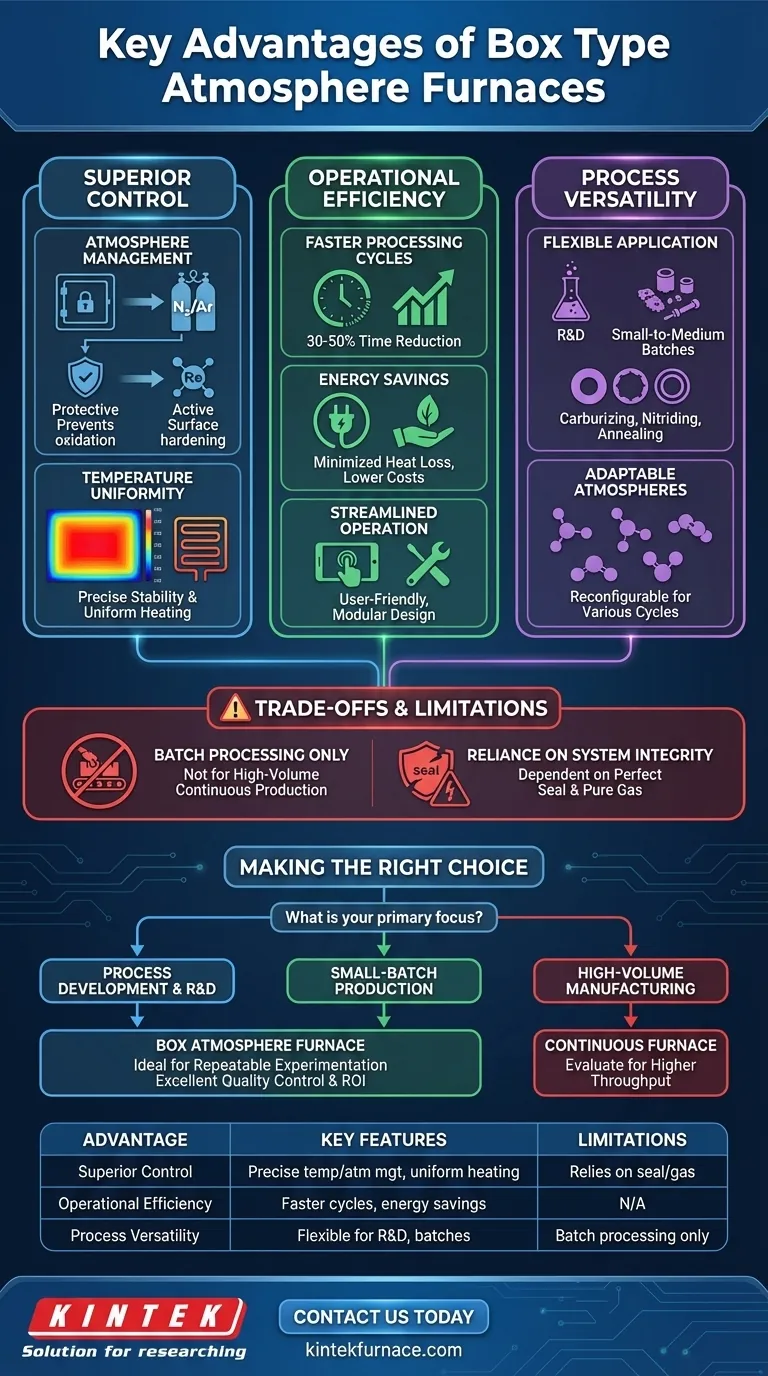

At its core, a box type atmosphere furnace provides three primary advantages over other heat treatment equipment: superior control, operational efficiency, and process versatility. It achieves this by creating a highly regulated environment where both the temperature and the gaseous atmosphere are precisely managed, ensuring repeatable, high-quality results for sensitive materials.

The true value of a box atmosphere furnace is not just its list of features, but how they combine to deliver predictable outcomes. It excels in applications where protecting a part from oxidation or inducing a specific surface reaction is just as critical as the heating cycle itself.

The Foundation of Control: Atmosphere and Temperature

The defining characteristic of this furnace type is its ability to manipulate the environment inside the chamber. This control is the key to unlocking specific material properties and ensuring component integrity.

Why Atmosphere Control is Critical

The atmosphere inside a furnace can play one of two crucial roles. It can be protective, using inert gases like nitrogen or argon to shield parts from the harmful effects of oxygen at high temperatures, preventing oxidation and decarburization.

Alternatively, the atmosphere can be active, acting as a carrier for elements that chemically react with the part's surface. This is fundamental for processes like carburizing or nitriding, which are designed to harden the material's surface.

Achieving a Stable Environment

These furnaces rely on an excellent seal to isolate the internal chamber from the outside air. Once sealed, a specific atmosphere can be introduced and maintained.

This is often achieved by purging the chamber with a protective gas, such as nitrogen or argon, creating a controlled environment that is essential for processing reactive or sensitive metals.

The Importance of Temperature Uniformity

Box atmosphere furnaces use electric heating elements—such as resistance wires or silicon carbon rods—to generate heat. This method, combined with high-quality insulation, allows for rapid heating and exceptional temperature stability.

Good temperature uniformity across the entire chamber ensures that every part in the batch, regardless of its position, experiences the exact same thermal cycle. This consistency is vital for achieving uniform material properties and reliable performance.

Driving Efficiency and Throughput

Beyond precision, the design of a modern box atmosphere furnace is focused on optimizing the entire heat treatment workflow, from energy consumption to maintenance.

Faster Processing Cycles

Compared to older or more traditional furnace designs, the combination of efficient heating and precise control can dramatically shorten processing times. For annealing processes, this can reduce the required furnace time by 30% to 50%.

Faster heating and cooling cycles directly translate to higher throughput for batch-based production, allowing more work to be completed in less time.

Energy Savings Through Precision

Efficient insulation minimizes heat loss to the surrounding environment. When paired with a control system that prevents temperature overshooting, the furnace consumes significantly less energy.

This precision ensures that energy is used only to heat the product, not wasted, leading to lower operational costs and a more environmentally friendly footprint.

Streamlined Operation and Maintenance

Modern furnaces feature user-friendly interfaces that simplify the process of setting parameters and monitoring the heat treatment cycle. This reduces the potential for operator error and improves process repeatability.

Furthermore, many are built with a modular design. This allows for key components to be quickly disassembled, replaced, or serviced, which minimizes downtime and improves the overall reliability of the equipment.

Understanding the Trade-offs and Limitations

No single piece of equipment is perfect for every task. Understanding where a box atmosphere furnace excels—and where it doesn't—is key to making an informed decision.

The Ideal Use Case: Flexibility Over Volume

The "box" design inherently means it is a batch-processing tool. It is perfectly suited for research and development, process validation, or the production of small-to-medium batches of high-value components.

Its strength lies in its flexibility to be reconfigured for different thermal cycles and atmospheres from one batch to the next.

Throughput vs. Continuous Production

This furnace is not designed for high-volume, continuous manufacturing. In scenarios where thousands of identical parts must be processed per hour, a continuous or conveyor-style furnace would be a far more efficient choice. The batch nature of a box furnace would become a production bottleneck.

Reliance on System Integrity

The primary advantage of atmosphere control is also its main vulnerability. The entire process is dependent on a perfect furnace seal and a pure, reliable gas supply. Any leak or contamination in the gas will compromise the atmosphere and negate the benefits, potentially ruining the entire batch.

Making the Right Choice for Your Application

Selecting the correct furnace requires aligning the equipment's core strengths with your specific goals.

- If your primary focus is process development and material research: The unparalleled control over temperature and atmosphere makes a box furnace the ideal tool for repeatable and documented experimentation.

- If your primary focus is small-batch production of high-value parts: The combination of quality control, process flexibility, and operational efficiency provides an excellent return on investment.

- If your primary focus is high-volume, low-mix manufacturing: You should evaluate continuous furnace types, as a batch-style box furnace will likely limit your overall throughput.

Ultimately, choosing the right tool begins with a clear understanding of its fundamental design advantages and how they serve your specific technical and business needs.

Summary Table:

| Advantage | Key Features |

|---|---|

| Superior Control | Precise temperature and atmosphere management, excellent sealing, uniform heating |

| Operational Efficiency | Faster processing cycles (30-50% time reduction), energy savings, user-friendly interfaces |

| Process Versatility | Flexible for R&D, small-to-medium batches, protective or active atmospheres |

| Limitations | Batch processing only, not for high-volume continuous production, relies on seal and gas purity |

Ready to enhance your lab's heat treatment capabilities? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our box type atmosphere furnaces can deliver superior control, efficiency, and versatility for your sensitive material processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage