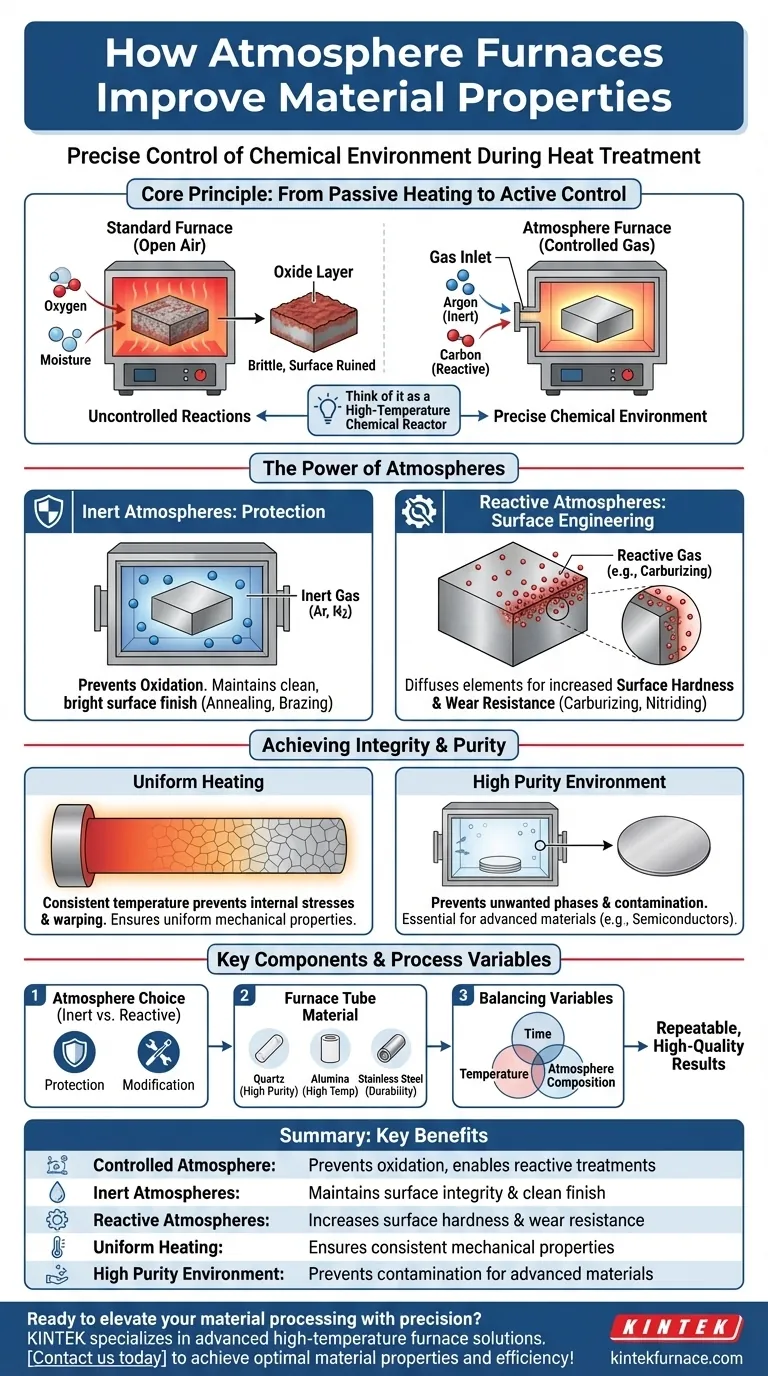

An atmosphere furnace improves material properties by giving you precise control over the chemical environment during heat treatment. Unlike a standard furnace that heats in open air, an atmosphere furnace allows you to replace the air with a specific gas or gas mixture. This precise control prevents unwanted chemical reactions like oxidation and enables targeted reactions that can fundamentally change a material's structure and performance.

Think of an atmosphere furnace not just as an oven, but as a high-temperature chemical reactor. By controlling the atmosphere, you are no longer a passive observer of heat's effects; you are an active director of the material's final properties.

The Core Principle: Moving Beyond Heating in Air

Heating a material in ambient air introduces oxygen and moisture, which can be highly reactive at elevated temperatures. An atmosphere furnace gives you the power to remove these variables and dictate the environment.

Why Heating in Air is a Problem

At high temperatures, most metals will readily react with oxygen in the air. This process, known as oxidation, forms a brittle, often undesirable, oxide layer on the material's surface.

This can ruin the surface finish, compromise dimensional accuracy, and create a weak outer layer that can flake off or lead to premature failure.

The Role of Inert Atmospheres

The most common use of an atmosphere furnace is to create a protective, or inert, environment. This is done by purging the air from the furnace chamber and replacing it with a non-reactive gas like argon or nitrogen.

By eliminating oxygen, you can heat a material without causing oxidation. This is critical for processes like annealing or brazing, where maintaining a clean, bright surface finish is essential for the final product's quality and performance.

Using Reactive Atmospheres for Surface Engineering

An atmosphere furnace can also introduce reactive gases to intentionally alter the surface chemistry of a material. This is a powerful technique for enhancing specific properties.

For example, introducing carbon-rich gases (carburizing) or nitrogen-rich gases (nitriding) can diffuse carbon or nitrogen into the surface of steel parts. This dramatically increases surface hardness and wear resistance while keeping the core of the material tough and ductile.

Achieving Structural Integrity and Purity

Beyond surface chemistry, the controlled environment of an atmosphere furnace is crucial for developing a material's internal structure and ensuring its overall quality.

The Importance of Uniform Heating

Atmosphere furnaces are designed to provide highly uniform heating. Consistent temperature throughout the part prevents internal stresses, warping, or the formation of an inconsistent microstructure.

This uniformity ensures that the entire component achieves the desired mechanical properties, such as consistent hardness, strength, and ductility, from edge to core.

Preventing Unwanted Phases and Contaminants

For advanced materials, such as those used in batteries or semiconductors, even trace amounts of contamination can be catastrophic. The sealed, controlled environment prevents airborne contaminants from reaching the material.

This control also ensures the material develops the correct crystallinity and purity. It prevents the formation of unwanted chemical phases, resulting in a material that performs exactly as designed.

Understanding the Trade-offs and Key Components

Successfully using an atmosphere furnace requires understanding how its components and settings interact to produce a final result. The choices you make directly impact the outcome.

Choosing the Right Atmosphere

The choice between an inert or reactive atmosphere is the most fundamental decision. Inert gases protect the material, while reactive gases are used to intentionally modify it. The wrong choice can either fail to produce the desired change or damage the material.

The Impact of the Furnace Tube Material

The tube or chamber that contains the material and atmosphere plays a critical role.

- Quartz tubes are used for the highest-purity applications, as quartz is very non-reactive, but it has temperature limitations.

- Alumina (a ceramic) offers excellent chemical resistance and thermal stability at very high temperatures.

- Stainless steel tubes provide durability and are often used for reducing or reactive atmospheres that might damage other materials.

Balancing Process Variables

Achieving the desired properties is a balancing act between three main variables: temperature, time, and atmosphere composition. These factors are interdependent, and precise control over all three is the key to repeatable, high-quality results.

Making the Right Choice for Your Goal

To apply this knowledge, align your furnace setup and process with your specific objective.

- If your primary focus is surface integrity and a clean finish: Use an inert gas atmosphere like argon or nitrogen to prevent oxidation during processes like annealing or brazing.

- If your primary focus is enhancing mechanical properties like hardness: Use a reactive atmosphere, such as in carburizing or nitriding, to engineer the material's surface chemistry.

- If your primary focus is high-purity material synthesis: Use high-purity inert gases and an appropriate non-reactive furnace tube, like quartz or alumina, to prevent contamination.

By moving from simple heating to controlled chemical processing, an atmosphere furnace empowers you to create materials with superior performance and reliability.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Controlled Atmosphere | Prevents oxidation, enables reactive treatments |

| Inert Atmospheres | Maintains surface integrity and clean finish |

| Reactive Atmospheres | Increases surface hardness and wear resistance |

| Uniform Heating | Ensures consistent mechanical properties |

| High Purity Environment | Prevents contamination for advanced materials |

Ready to elevate your material processing with precision? KINTEK specializes in advanced high-temperature furnace solutions, including Atmosphere Furnaces, designed for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements. Our product line features Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, ensuring superior performance and reliability. Contact us today to discuss how we can help you achieve optimal material properties and efficiency in your lab!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.