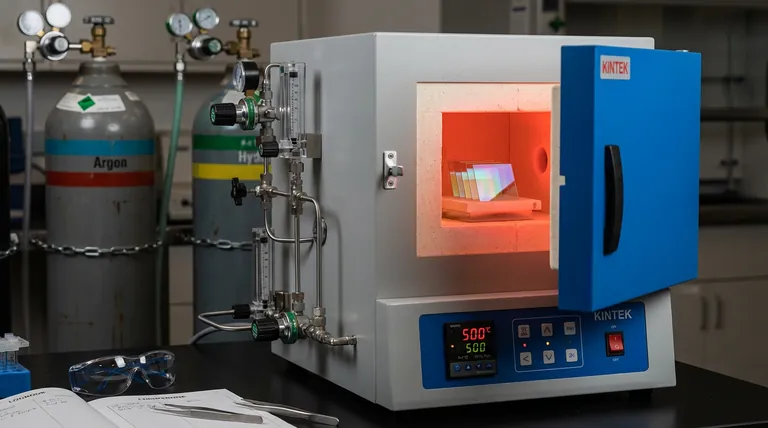

Atmosphere control is the defining factor in optimizing the electrical properties of Al-doped ZnO (AZO) thin films. By utilizing a programmable high-temperature annealing furnace to create a reducing atmosphere—specifically an argon-hydrogen mixture—you significantly enhance the material's electrical conductivity.

Core Takeaway The furnace improves performance by maintaining a low oxygen partial pressure during the final 500°C heat treatment. This specific environmental condition drives preferential crystal growth along the [002] direction and increases carrier concentration, resulting in superior electrical conductivity.

Mechanisms of Performance Enhancement

The Role of Reducing Atmospheres

To maximize performance, the furnace must be programmed to introduce a reducing atmosphere, such as an argon-hydrogen mixture (Ar + 1% H2).

This mixture creates a critically low oxygen partial pressure environment within the chamber. Unlike standard oxidation atmospheres, this reducing environment is the catalyst for the material changes described below.

Optimizing Crystal Orientation

The controlled atmosphere directly influences the structural evolution of the thin film.

Under these reducing conditions, the AZO film exhibits preferential crystal growth along the [002] direction. This structural alignment is essential for minimizing grain boundary scattering, which helps improve electron mobility.

Boosting Electrical Conductivity

The most tangible benefit of this atmospheric control is a significant increase in carrier concentration.

By limiting oxygen availability during the 500°C anneal, the furnace encourages the formation of oxygen vacancies or allows the aluminum dopants to activate more effectively. This increase in charge carriers directly translates to enhanced electrical conductivity in the final device.

Precision Control Capabilities

Accurate Gas Regulation

A high-quality atmosphere furnace utilizes high-precision gas flow meters and pressure regulating devices.

This ensures the concentration and flow rate of the Ar + H2 mixture remain stable throughout the process. Uniformity in the gas environment ensures that the conductive properties are consistent across the entire surface of the thin film.

Thermal Stability at 500°C

The programmable nature of the furnace allows for a precise final heat treatment at 500°C.

At this temperature, the thermal energy is sufficient to rearrange the crystal lattice without damaging the substrate, provided the atmosphere is correctly maintained.

Understanding the Trade-offs

The Risk of Skipping Pre-Treatment

While the high-temperature atmosphere furnace optimizes electrical properties, it cannot replace preliminary steps.

You must perform a preliminary heat treatment at 350°C (often in a tube resistance furnace) to evaporate organic solvents and prevent peeling or cracking. Skipping to the high-temperature step immediately can destroy the film's physical integrity before the electrical properties can be optimized.

Atmosphere Sensitivity

The choice of gas is binary in its effect on performance.

Using an oxidizing atmosphere (like pure oxygen) or low vacuum without hydrogen will result in different film properties. If your goal is high conductivity, failing to use a reducing atmosphere (Ar + H2) will render the annealing process ineffective for increasing carrier concentration.

Making the Right Choice for Your Goal

To achieve the best results with your AZO thin films, configure your furnace parameters based on the following priorities:

- If your primary focus is maximum electrical conductivity: Program the furnace for a final anneal at 500°C using an Ar + 1% H2 reducing atmosphere to maximize carrier concentration.

- If your primary focus is film structural integrity: Ensure you complete the preliminary 350°C heat treatment to remove solvents and prevent cracking before attempting the high-temperature atmospheric anneal.

Success depends on combining the structural stability of pre-treatment with the chemical optimization of a reducing atmosphere.

Summary Table:

| Parameter | Process Condition | Impact on AZO Film Performance |

|---|---|---|

| Atmosphere Type | Reducing (Ar + 1% H2) | Increases carrier concentration & conductivity |

| Temperature | 500°C (Final Anneal) | Provides thermal energy for lattice rearrangement |

| Crystal Orientation | [002] Direction | Minimizes grain boundary scattering |

| Pre-treatment | 350°C (Air/Tube Furnace) | Removes organic solvents to prevent cracking |

| Oxygen Pressure | Low Partial Pressure | Facilitates oxygen vacancy formation |

Elevate Your Material Research with KINTEK

Maximize the potential of your Al-doped ZnO (AZO) thin films with precision-engineered thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific atmosphere and temperature requirements. Whether you need stable reducing environments or precise 500°C thermal control, our lab high-temp furnaces provide the reliability your research demands.

Ready to optimize your thin film conductivity? Contact KINTEK today for a custom solution!

References

- Alberto Giribaldi, Paolo Mele. Enhancing Thermoelectric Performance: The Impact of Carbon Incorporation in Spin-Coated Al-Doped ZnO Thin Films. DOI: 10.3390/coatings15010107

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does the box type annealing atmosphere furnace improve material quality? Enhance Strength, Ductility, and Surface Integrity

- What are the technical advantages of a Zero-reforming Vertical Furnace? Revolutionize Green DRI Production Today

- What are the key applications of a controlled atmosphere furnace? Unlock Precise Material Processing

- Why is precise temperature control in a tube atmosphere furnace critical? Optimize Your Oxide Precursor Sintering

- What are the operational considerations for atmosphere furnaces? Master Precise Control for Safe, Efficient Results

- How does a laboratory electric furnace support the process of evaluating the light-off temperature of Pd/Al2O3 catalysts?

- What is the purpose of the 1000 °C pre-annealing treatment for copper foil? Optimize acm-BN Growth Success

- What is the purpose of inerting in heat treatment furnaces? Prevent Oxidation and Ensure Safety