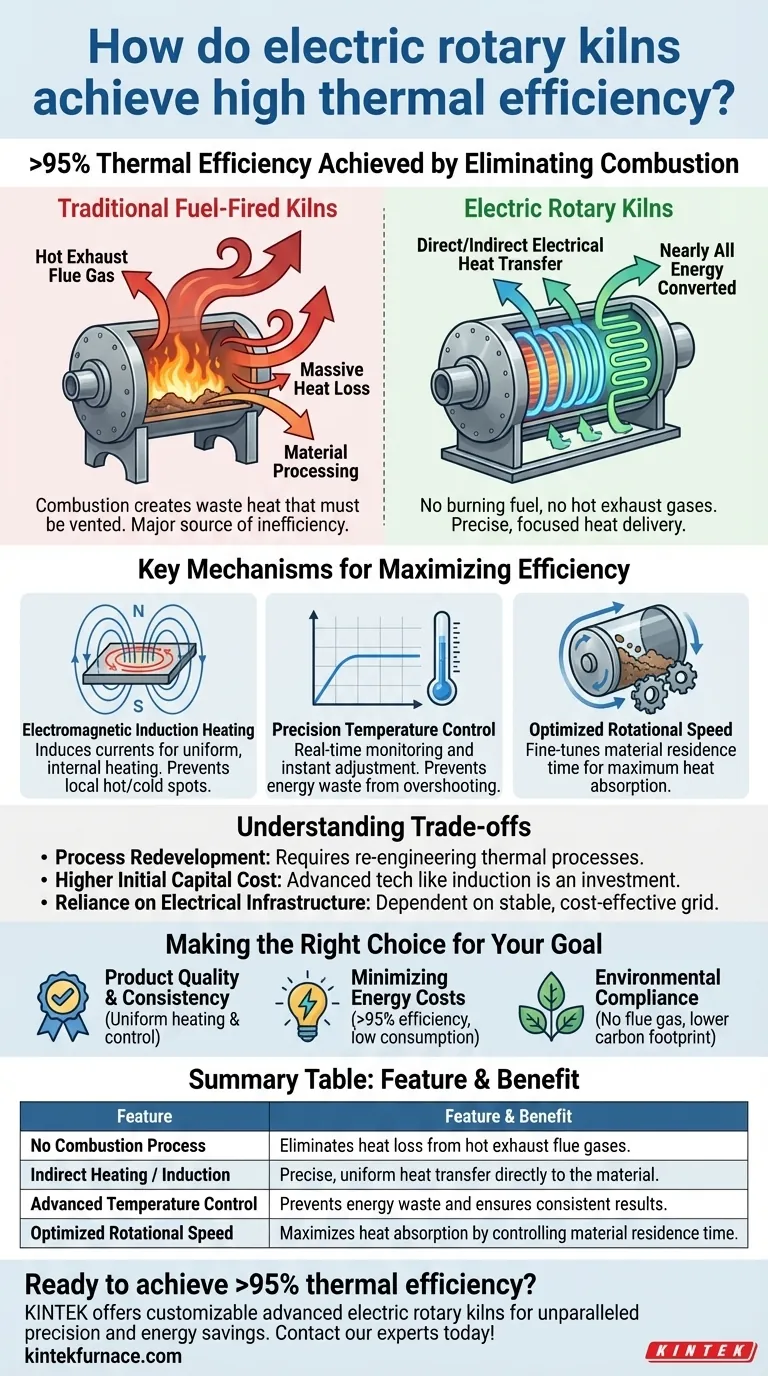

The short answer is that electric rotary kilns achieve thermal efficiency above 95% because they eliminate the single largest source of heat loss found in traditional kilns: combustion. Without burning fuel, there are no hot exhaust gases that must be vented, which means nearly all the electrical energy is converted directly into useful heat for processing the material.

The fundamental advantage of electric rotary kilns is their ability to deliver energy precisely where it's needed without the inherent waste of a combustion process. This shift from burning fuel to applying controlled electricity fundamentally redefines the efficiency ceiling for thermal processing.

The Core Principle: Eliminating Combustion Waste

Traditional fuel-fired kilns are fundamentally inefficient because a significant portion of the heat generated is immediately lost. Understanding why electric kilns are different starts with this key concept.

The Problem with Flue Gas

In any kiln powered by natural gas, oil, or coal, the fuel must be burned to create heat. The byproducts of this combustion—hot exhaust gases, often called flue gas—must be continuously removed from the kiln.

This stream of exhaust carries a massive amount of thermal energy out of the system. This is an unavoidable and primary source of heat loss that electric kilns simply do not have.

Direct vs. Indirect Heating

Electric heating allows for more efficient methods of heat transfer. Some systems replace a gas burner with an electric hot gas generator, but the most efficient designs re-imagine the process entirely.

Many electric kilns use an indirect heating method. Heating elements or electromagnetic induction coils are placed outside the rotating drum, transferring heat through the kiln wall to the material inside. This isolates the material from the heating source, ensuring clean processing and minimal energy loss to the surrounding environment.

Key Mechanisms for Maximizing Efficiency

Beyond just eliminating combustion, electric kilns leverage several design and operational features to achieve near-perfect thermal performance.

Electromagnetic Induction Heating

Advanced electric kilns use electromagnetic induction to generate heat. This technology uses magnetic fields to induce electrical currents directly within the material or the kiln's conductive shell, causing it to heat up from the inside out.

This method is exceptionally uniform and controllable, ensuring that energy is delivered precisely and evenly throughout the material load. It prevents the local overheating or underheating that plagues less advanced systems.

Precision Control of Temperature

Electric systems offer unparalleled control. Thermocouples monitor the material's temperature in real time, and the power to the heaters can be adjusted instantly.

This allows the kiln to maintain a precise temperature setpoint without overshooting, which wastes energy. The entire heating cycle can be programmed and executed flawlessly, ensuring consistent results and optimal energy use.

Optimized Rotational Speed

The rotation of the kiln drum is critical for heat transfer. It ensures the material tumbles and exposes all surfaces to the heat source.

Rotational speed directly controls the material's residence time. If the speed is too high, the material passes through too quickly to absorb the heat fully. If it's too slow, material can build up, creating insulating cold spots. Electric kilns allow for fine-tuning this speed to match the material and process, maximizing heat absorption.

Understanding the Trade-offs

While highly efficient, transitioning to electric rotary kilns involves important considerations.

Process Redevelopment

Converting a direct-fired gas kiln to an efficient indirect electric model is not a simple swap. It often requires a deep understanding of the thermal process to redevelop it for a different heating method. This can be a significant engineering challenge.

Higher Initial Capital Cost

Advanced systems, particularly those using electromagnetic induction, can have a higher upfront capital cost compared to traditional combustion-based kilns. This initial investment must be weighed against long-term energy savings and improved product quality.

Reliance on Electrical Infrastructure

The efficiency and cost-effectiveness of an electric kiln are directly tied to the stability and price of the electrical grid. Operations in areas with unreliable or expensive electricity may face challenges that combustion-based systems do not.

Making the Right Choice for Your Goal

The decision to use an electric rotary kiln should be based on your primary operational driver.

- If your primary focus is product quality and consistency: The uniform heating and precise temperature control of an electric kiln, especially an induction model, are unmatched.

- If your primary focus is minimizing energy costs: The thermal efficiency exceeding 95% dramatically reduces long-term energy consumption compared to any fuel-fired alternative.

- If your primary focus is environmental compliance: The elimination of flue gas simplifies emissions treatment and significantly lowers your carbon footprint.

By fundamentally changing how heat is generated and delivered, electric rotary kilns represent a leap forward in thermal processing efficiency.

Summary Table:

| Feature | Benefit |

|---|---|

| No Combustion Process | Eliminates heat loss from hot exhaust flue gases. |

| Indirect Heating / Induction | Precise, uniform heat transfer directly to the material. |

| Advanced Temperature Control | Prevents energy waste from overshooting and ensures consistent results. |

| Optimized Rotational Speed | Maximizes heat absorption by controlling material residence time. |

Ready to achieve >95% thermal efficiency in your thermal processing?

Backed by expert R&D and manufacturing, KINTEK offers advanced electric rotary kilns that deliver unparalleled precision and energy savings. Our systems are customizable to your unique material and process requirements, helping you reduce operational costs and improve product quality.

Contact our experts today to discuss how an electric rotary kiln can transform your operations!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are the main components in the construction of a rotary kiln? A Guide to the Core Systems