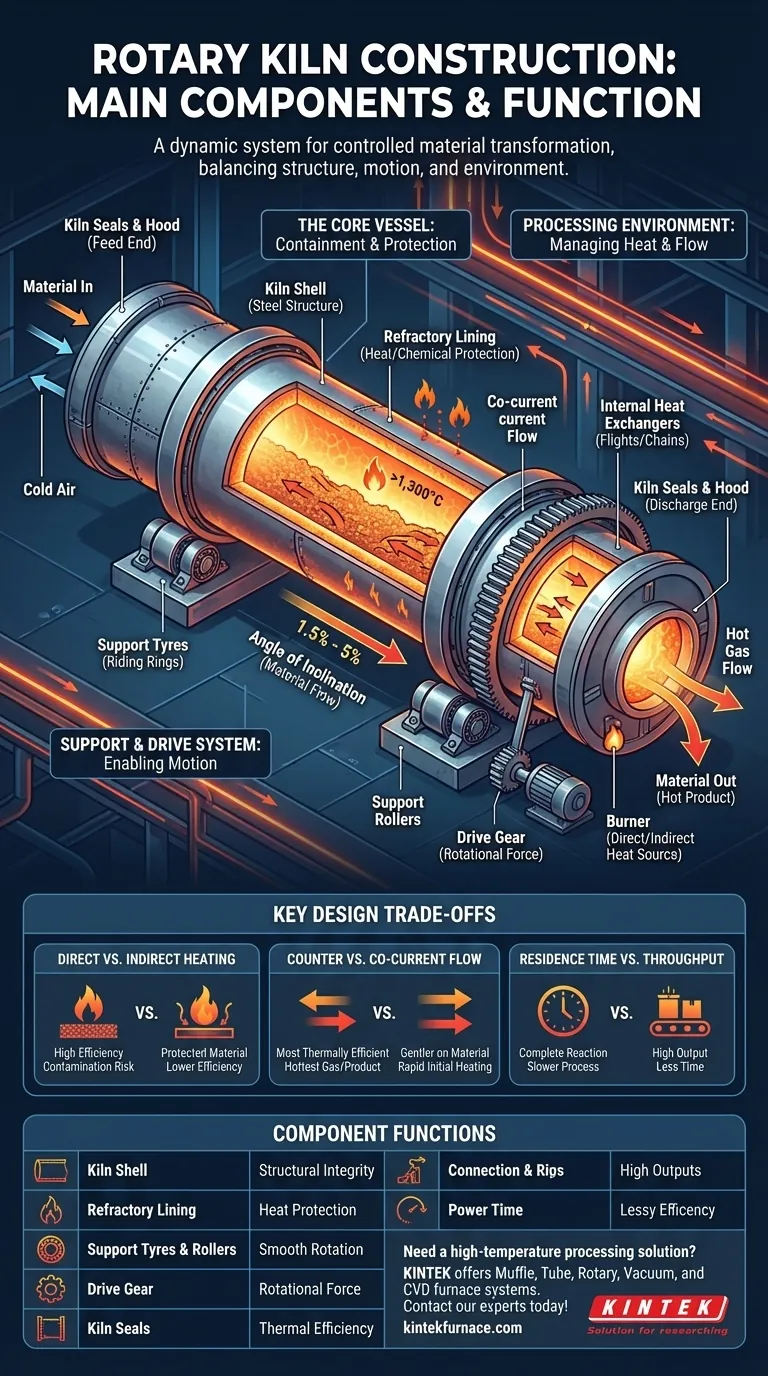

At its core, a rotary kiln is constructed from a few primary components designed to work in concert. These include the main rotating cylinder or shell, a protective internal refractory lining, a support system of tyres and rollers that allows it to turn, and a drive gear to provide the rotational force. The entire assembly is set at a slight angle to guide material through the heating process.

A rotary kiln is not merely a heated, rotating tube. It is a dynamic system where the structural components, support mechanism, and heating elements are all precisely engineered to control the movement, residence time, and temperature of materials undergoing a physical or chemical transformation.

The Core Vessel: Containment and Protection

The main body of the kiln is a massive cylindrical structure responsible for containing the entire process. Its design balances structural integrity with thermal and chemical resistance.

The Kiln Shell

The kiln shell is the outer backbone of the entire structure. It is a large, hollow cylinder fabricated from welded mild steel plates, often between 15 and 30 mm thick.

The shell provides the fundamental structural integrity needed to span the support rollers and withstand the immense mechanical stresses of rotation and thermal expansion.

The Refractory Lining

Inside the steel shell is the refractory lining, a critical layer of heat- and chemical-resistant material. This lining serves two primary purposes.

First, it protects the steel shell from the extreme internal temperatures—which can exceed 1,300°C (2,372°F)—preventing it from warping or failing. Second, it minimizes heat loss, retaining thermal energy within the kiln to improve overall efficiency.

The Support and Drive System: Enabling Motion

The ability to rotate smoothly and consistently is fundamental to the kiln's operation. This is managed by a robust system of supports and a powerful drive mechanism.

Support Tyres and Rollers

Heavy steel rings known as support tyres (or riding rings) are attached to the outside of the kiln shell. These tyres rest on sets of support rollers.

This arrangement carries the entire weight of the kiln and allows the massive cylinder to rotate with minimal friction, ensuring smooth and stable operation.

The Drive Gear

The rotational force, or torque, is delivered by the drive gear. This is typically a large ring gear that encircles and is fixed to the kiln shell, which is turned by a smaller pinion gear connected to a motor.

Modern kilns often use variable-speed drives to precisely control the rotational speed, which is a key parameter for managing how long the material stays inside the kiln.

The Angle of Inclination

The entire kiln assembly is mounted at a slight downward angle of inclination, typically between 1.5% and 5%.

This tilt is not a passive feature; it is a critical design element. Combined with the kiln's rotation, this angle dictates the speed at which solid materials travel from the feed end to the discharge end.

The Processing Environment: Managing Heat and Material Flow

The ultimate purpose of the kiln is to create a controlled environment for processing materials. This involves a heat source, sealing mechanisms, and sometimes internal components to enhance efficiency.

Heating Systems and Flow

Heat can be applied directly, where hot gases pass through the kiln in contact with the material, or indirectly, where the shell is heated from the outside.

The flow of these hot gases can be co-current (in the same direction as the material) or counter-current (in the opposite direction), a choice that significantly impacts thermal efficiency.

Kiln Seals and Hood

Seals are installed at both the feed and discharge ends of the kiln. Their purpose is to prevent cold air from leaking into the system and hot gases from escaping, which is vital for maintaining temperature control and thermal efficiency.

A kiln hood at the discharge end often houses the burner (in direct-fired systems) and manages the transition of the hot product to the next stage of processing.

Internal Heat Exchangers

To improve thermal efficiency, some kilns are fitted with internal heat exchangers. These can be simple "lifting flights" that shower material through the hot gas stream, or more complex chain systems.

These components increase the contact between the material and the heating medium, ensuring a more uniform and efficient transfer of heat.

Key Design Trade-offs

The selection and configuration of these components are driven by the specific process requirements, leading to critical design trade-offs.

Direct vs. Indirect Heating

Direct heating is more thermally efficient because the heat source is in direct contact with the material. However, this can contaminate sensitive products with combustion byproducts.

Indirect heating protects the material from contamination but is less efficient and generally limited to lower-temperature applications.

Counter-Current vs. Co-Current Flow

Counter-current flow, where material and hot gas move in opposite directions, is the most thermally efficient configuration. The hottest gases encounter the most processed material, maximizing heat transfer.

Co-current flow, where they move in the same direction, is gentler on heat-sensitive materials. It exposes the cold, wet feed to the hottest gases first, providing rapid initial heating without overheating the final product.

Residence Time vs. Throughput

The residence time—how long the material spends in the kiln—is controlled by the angle of inclination and rotational speed. A lower angle and slower rotation increase residence time, allowing for more complete reactions.

However, this reduces throughput, or the amount of material processed per hour. The final design must balance the need for a complete reaction with the economic demand for high output.

How Components Align with Processing Goals

Your choice of kiln configuration depends entirely on the material you are processing and your primary objective.

- If your primary focus is maximum thermal efficiency: You will prioritize a direct-fired, counter-current system with a robust refractory lining and internal heat exchangers to minimize energy loss.

- If your primary focus is processing a heat-sensitive or delicate material: You will likely require a co-current or indirect heating system to avoid thermal shock or contamination.

- If your primary focus is achieving a very specific chemical reaction: You will need precise control over residence time through a variable-speed drive and an optimized angle of inclination.

Understanding how each component contributes to the whole allows you to select or design a rotary kiln that is perfectly suited to its intended task.

Summary Table:

| Component | Primary Function |

|---|---|

| Kiln Shell | Main structural cylinder providing integrity. |

| Refractory Lining | Protects shell from extreme heat and minimizes energy loss. |

| Support Tyres & Rollers | Supports the kiln's weight and enables smooth rotation. |

| Drive Gear | Provides the rotational force for the kiln. |

| Kiln Seals | Prevent air leakage and maintain thermal efficiency. |

Need a high-temperature processing solution tailored to your specific material and throughput goals?

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for unique needs. Our team can help you select or design the ideal system to maximize your thermal efficiency and processing outcomes.

Contact our experts today to discuss your application!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency