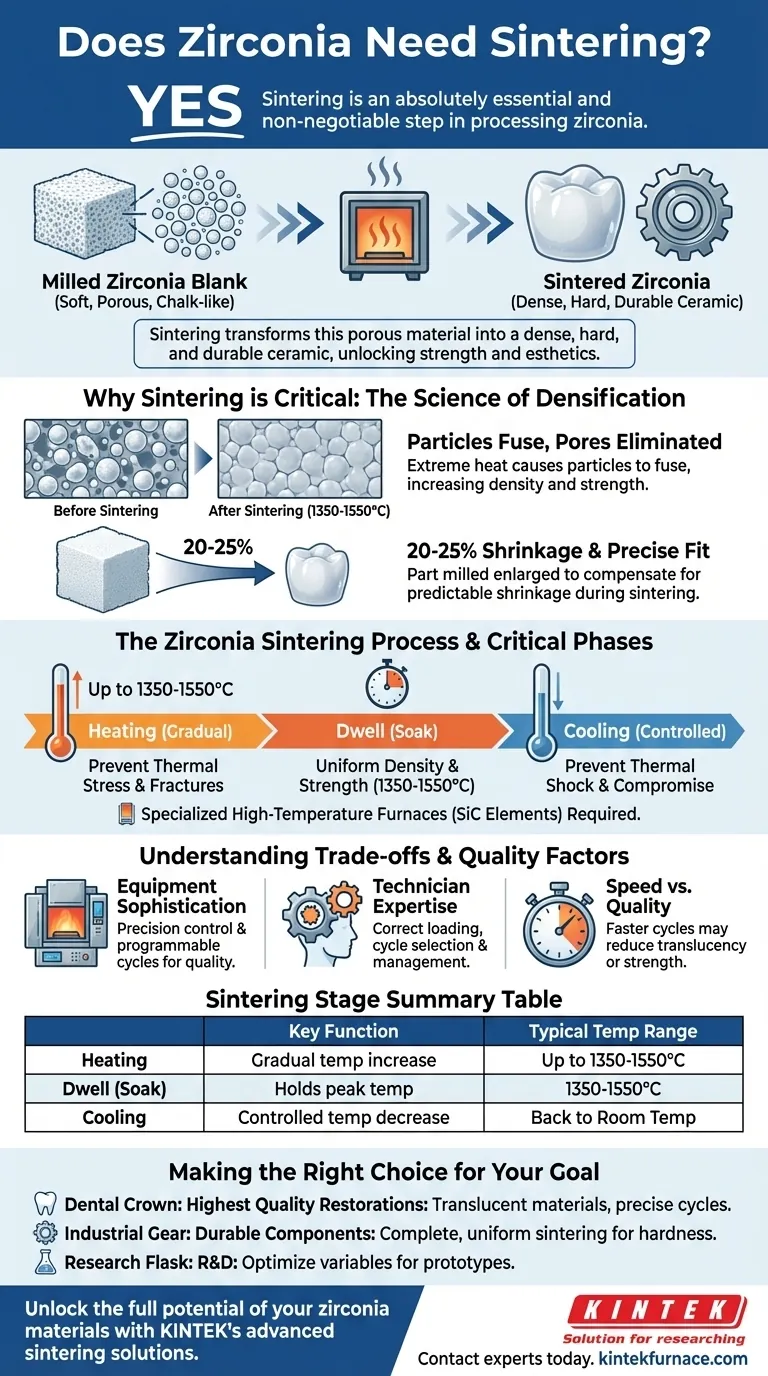

Yes, sintering is an absolutely essential and non-negotiable step in processing zirconia. After being milled from a blank, zirconia exists in a soft, chalk-like state that is easy to shape but lacks the necessary properties for its final application. The sintering process uses extreme heat to transform this porous material into a dense, hard, and durable ceramic, unlocking the strength and esthetics zirconia is known for.

Sintering is not merely a finishing step; it is the fundamental metallurgical transformation that gives zirconia its strength, durability, and esthetic properties. Without it, a milled zirconia part is unusable for any high-performance application, from dental crowns to industrial components.

What is Sintering and Why is it Critical?

Sintering is a high-temperature process that fundamentally changes the physical structure of zirconia. Understanding this transformation is key to appreciating why it cannot be skipped.

From a Porous State to a Solid Structure

Before sintering, a milled zirconia restoration consists of fine ceramic particles that have been pressed together. While it holds its shape, it is porous, weak, and opaque.

The sintering process heats the material to a temperature just below its melting point, typically between 1350°C and 1550°C (2462°F and 2822°F).

The Science of Densification

At these extreme temperatures, the individual zirconia particles fuse together at their contact points. This process, known as densification, eliminates the pores between the particles.

As the material becomes denser, it becomes significantly stronger and more fracture-resistant. This is the source of zirconia's exceptional mechanical properties.

The Impact on Shrinkage and Fit

A critical consequence of densification is predictable shrinkage. A zirconia part will shrink by approximately 20-25% during the sintering cycle.

To achieve the correct final dimensions, the part must be milled in an enlarged state. This requires sophisticated design software and precise calibration between the scanner, software, and furnace to ensure an accurate fit.

The Zirconia Sintering Process

The sintering process is more than just heating and cooling; it is a precisely controlled cycle where each stage is vital for the quality of the final product.

Specialized High-Temperature Furnaces

Sintering zirconia requires a special furnace capable of reaching and maintaining very high temperatures with extreme accuracy. Standard dental porcelain furnaces cannot reach these temperatures.

These furnaces often use robust silicon carbide (SiC) heating elements, which are durable and chemically compatible with the zirconia sintering environment.

The Three Critical Phases

- Heating: The furnace temperature is raised gradually according to a specific program. Heating too quickly can introduce thermal stress and cause fractures.

- Dwell (or Soak): The furnace holds the material at the peak target temperature for a set period. This "soaking" phase ensures the entire restoration reaches a uniform density.

- Cooling: The temperature is brought down in a controlled manner. Just like rapid heating, rapid cooling can cause thermal shock and compromise the integrity of the zirconia.

Understanding the Trade-offs and Quality Factors

Achieving a perfect outcome with zirconia is not automatic. It depends on a combination of technology, materials, and technical skill.

Equipment Sophistication Matters

The quality and consistency of the final restoration are directly linked to the quality of the sintering furnace. Advanced furnaces offer more precise temperature control and programmable cycles tailored to different types of zirconia.

Technician Expertise is Crucial

A skilled technician understands how to correctly load the furnace, select the appropriate sintering cycle for the specific material, and manage the process to avoid common pitfalls. Their expertise is a critical factor in producing high-quality, customized outcomes.

Speed vs. Quality Cycles

Many modern furnaces offer "speed" sintering cycles that can dramatically reduce processing time. While highly efficient, these faster cycles can sometimes result in lower translucency or slightly reduced strength compared to longer, conventional cycles. The choice involves a trade-off between turnaround time and maximum esthetic potential.

Making the Right Choice for Your Goal

The sintering process must be aligned with the intended application of the zirconia part. Your approach should be dictated by your primary objective.

- If your primary focus is producing the highest quality dental restorations: Invest in a reliable, high-temperature sintering furnace and ensure technicians are expertly trained on the specific cycles required for modern translucent zirconia materials.

- If your primary focus is manufacturing durable jewelry or industrial components: Recognize that a complete and uniform sintering cycle is the key to unlocking the hardness and wear-resistance that makes zirconia a superior material.

- If your primary focus is material research and development: Treat the sintering cycle—temperature, dwell time, and cooling rate—as a critical variable for optimizing the final mechanical and optical properties of your zirconia prototypes.

Ultimately, mastering the sintering process is fundamental to leveraging the full potential of zirconia and achieving consistently exceptional results.

Summary Table:

| Sintering Stage | Key Function | Typical Temperature Range |

|---|---|---|

| Heating | Gradual temperature increase to prevent thermal stress and fractures. | Up to 1350-1550°C |

| Dwell (Soak) | Holds peak temperature to ensure uniform density and strength. | 1350-1550°C |

| Cooling | Controlled temperature decrease to prevent thermal shock. | Back to room temperature |

Unlock the full potential of your zirconia materials with KINTEK's advanced sintering solutions.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique sintering requirements—whether for high-translucency dental restorations or ultra-durable industrial components.

Contact our experts today to discuss how our furnaces can ensure consistent, high-quality results for your zirconia applications.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What safety features are built into dental lab equipment furnaces? Ensure Operator and Equipment Protection

- What are the consequences of using incorrect temperature settings in a dental furnace? Avoid Costly Restoration Failures

- What are the two main types of dental porcelain furnace systems? Choose the Right One for Your Lab

- What are the two main types of porcelain furnaces? Choose the Right Furnace for Superior Dental Restorations

- Why is a vacuum heat treatment furnace essential for lithium disilicate? Achieve Superior Dental Strength

- What are the benefits of using a zirconia sintering furnace? Achieve Strong, Aesthetic Dental Restorations

- What are the advantages of using a porcelain furnace for dental restorations? Achieve Superior Aesthetics and Durability

- What advantages do zirconia sintering furnaces provide for dental restorations? Boost Strength, Aesthetics, and Lab Efficiency