The most critical safety features in modern dental lab furnaces are automated systems designed to prevent catastrophic failure. These include automatic shut-offs that activate when temperature or pressure exceeds safe limits, integrated alarms to alert operators of any malfunction, and specialized protections against issues like gas leaks or component breakage.

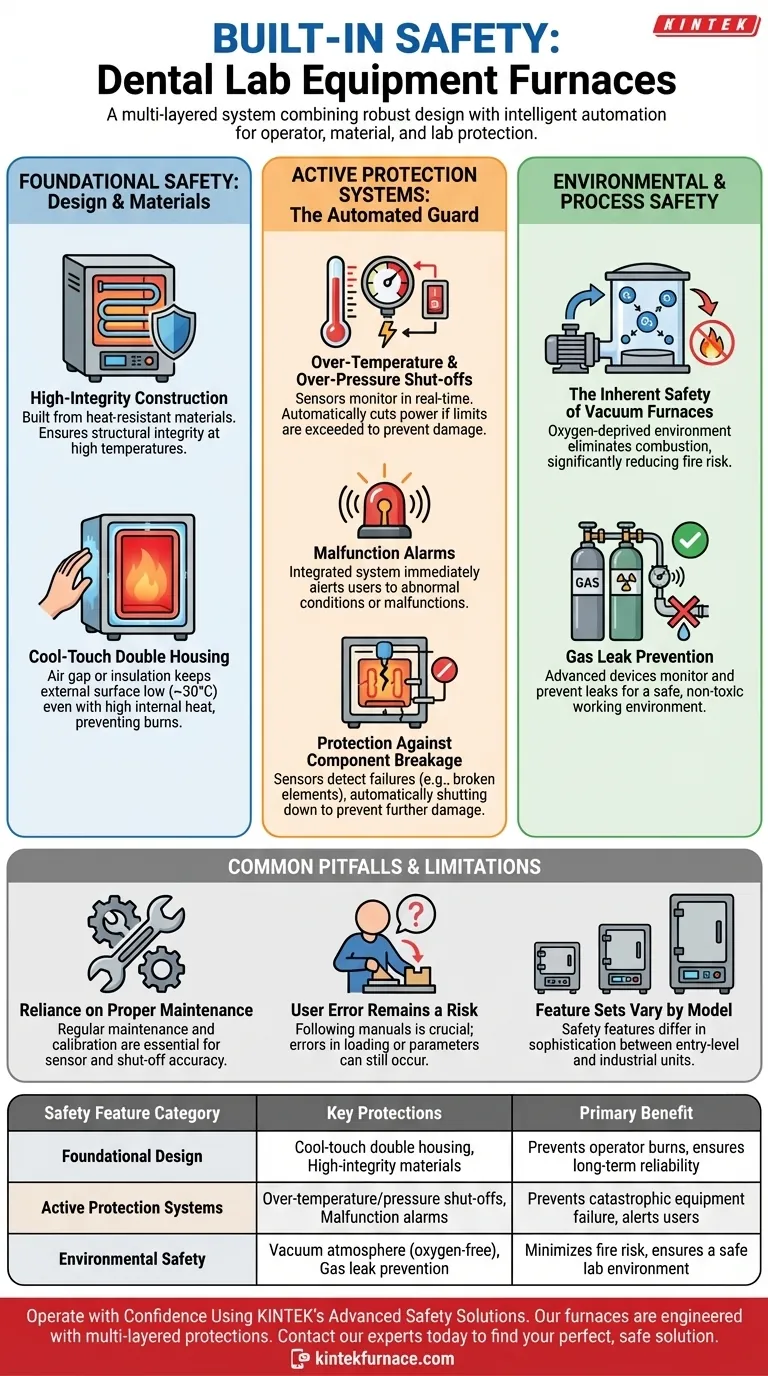

The safety of a dental lab furnace is not a single feature, but a layered system. It combines robust physical construction (passive safety) with intelligent, automated monitoring systems (active safety) to protect the user, the materials, and the lab environment.

Foundational Safety: Design and Materials

The first line of defense in furnace safety is its physical construction. The materials and design are engineered to withstand extreme conditions and contain energy effectively.

High-Integrity Construction

Modern furnaces are built from high-quality, heat-resistant materials. This ensures the furnace body and internal tubes maintain their structural integrity at very high temperatures, providing long-term reliability and stability.

Cool-Touch Double Housing

A key design feature is the use of a double housing. This creates an air gap or insulation layer that keeps the external surface temperature remarkably low, often around 30°C, even when the internal temperature is 800°C or higher. This drastically reduces the risk of accidental burns for operators.

Active Protection Systems: The Automated Guard

While physical design contains the heat, active systems monitor the furnace's operation in real time to prevent conditions from becoming dangerous in the first place.

Over-Temperature and Over-Pressure Shut-offs

This is the most fundamental active safety feature. Sensors constantly monitor the internal temperature and pressure. If these readings exceed pre-set safety limits, the system automatically cuts power to the heating elements, preventing overheating that could damage the furnace or the dental materials.

Malfunction Alarms

An integrated alarm system immediately alerts the user to any abnormal condition or equipment malfunction. This audible or visual cue ensures that potential problems are addressed before they can escalate.

Protection Against Component Breakage

Some advanced furnaces include sensors that can detect mechanical failures, such as a cracked heating element or tube. In the event of a breakage, the equipment can automatically shut down to prevent further damage.

Environmental and Process Safety

Beyond protecting the furnace itself, certain features are designed to protect the surrounding lab and the integrity of the process.

The Inherent Safety of Vacuum Furnaces

Vacuum furnaces operate in an oxygen-deprived environment. By removing the oxygen, they eliminate a key component required for combustion, which significantly reduces the risk of fire. This controlled atmosphere is one of the most effective safety enhancements available.

Gas Leak Prevention

For furnaces that use specific gases in their processes, advanced safety devices are included to monitor and prevent gas leaks. This is critical for ensuring a safe and non-toxic working environment for all lab personnel.

Common Pitfalls and Limitations

Even the most advanced safety systems have limitations. Understanding these is crucial for maintaining a truly safe operation.

Reliance on Proper Maintenance

Safety features are only effective if they are functioning correctly. Regular maintenance and calibration are essential to ensure that sensors are accurate and automatic shut-offs will trigger when needed.

User Error Remains a Risk

No safety system can completely eliminate the possibility of user error. Failing to follow the manufacturer's user manual, loading materials incorrectly, or setting improper parameters can still lead to undesirable outcomes.

Feature Sets Vary by Model

It is critical to remember that not all furnaces are created equal. The presence, sophistication, and reliability of these safety features can differ significantly between entry-level models and high-end industrial units.

Making the Right Choice for Your Goal

When evaluating a furnace, match its safety features to your lab's primary concerns.

- If your primary focus is operator protection: Prioritize models with cool-touch double housing and clear, comprehensive alarm systems.

- If your primary focus is preventing equipment damage: Ensure the furnace has precise and reliable over-temperature and over-pressure shut-off systems.

- If your primary focus is minimizing fire risk: A vacuum furnace offers the most inherently safe environment by removing oxygen from the process entirely.

Ultimately, a deep understanding of these safety systems empowers you to operate the equipment with confidence and create a secure laboratory environment.

Summary Table:

| Safety Feature Category | Key Protections | Primary Benefit |

|---|---|---|

| Foundational Design | Cool-touch double housing, High-integrity materials | Prevents operator burns, ensures long-term reliability |

| Active Protection Systems | Over-temperature/pressure shut-offs, Malfunction alarms | Prevents catastrophic equipment failure, alerts users |

| Environmental Safety | Vacuum atmosphere (oxygen-free), Gas leak prevention | Minimizes fire risk, ensures a safe lab environment |

Operate with Confidence Using KINTEK's Advanced Safety Solutions

Your dental lab's safety is paramount. KINTEK's high-temperature furnaces are engineered with a multi-layered safety system, integrating robust construction with intelligent, automated monitoring to protect your operators, your valuable materials, and your laboratory.

Our Muffle, Tube, and Vacuum Furnaces feature the critical protections detailed above—from cool-touch housings to precise automatic shut-offs. Leveraging our exceptional in-house R&D and manufacturing, we offer strong deep customization capabilities to precisely meet your unique safety and experimental requirements.

Ensure a secure lab environment. Contact our experts today to find the perfect, safe furnace solution for your dental laboratory.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations