The primary benefits of a zirconia sintering furnace are its ability to produce exceptionally strong, highly aesthetic, and biocompatible dental restorations with remarkable consistency. These furnaces achieve this by providing a precisely controlled high-temperature environment that transforms the pre-sintered zirconia material, a process essential for achieving the final desired clinical properties.

A zirconia sintering furnace is more than just an oven; it is a precision instrument at the heart of modern dental restoration. Its core function is to control the molecular transformation of zirconia, ensuring every restoration achieves maximum strength, ideal aesthetics, and predictable, repeatable outcomes.

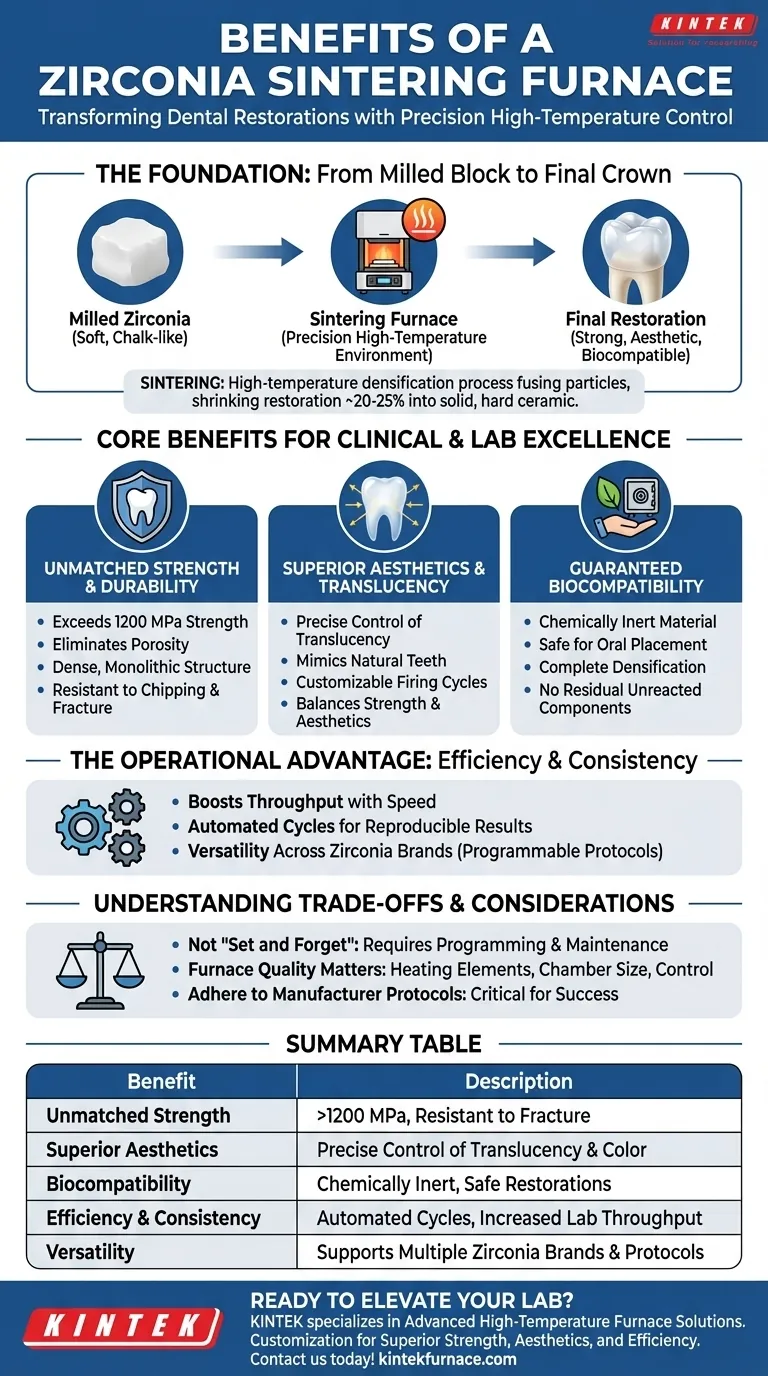

The Foundation: From Milled Block to Final Crown

To understand the benefits of a dedicated furnace, you must first understand the material it processes. Zirconia restorations begin as a soft, chalk-like block that is easy to mill. The sintering furnace provides the critical final step.

What is Sintering?

Sintering is a high-temperature process that causes the individual particles in the milled zirconia to bond and fuse together. This densification shrinks the restoration by about 20-25% and transforms it into a solid, incredibly hard ceramic.

The Role of Precision Temperature Control

The final strength, color, and translucency of a zirconia restoration are directly dictated by the temperature and duration of the sintering cycle. Advanced furnaces allow for precise, multi-stage programming to control these variables, ensuring the material's properties are fully and correctly developed.

Core Benefits for Clinical and Lab Excellence

A specialized furnace is not a luxury but a necessity for leveraging the full potential of zirconia. The benefits are seen in the final product and the efficiency of the workflow.

Unmatched Strength and Durability

Proper sintering is what gives zirconia its legendary strength, often exceeding 1200 MPa. This process eliminates porosity and creates a dense, monolithic structure that is highly resistant to chipping and fracture, ensuring long-lasting clinical performance.

Superior Aesthetics and Translucency

Modern zirconia materials offer a range of translucencies to mimic natural teeth. A quality furnace with customizable firing cycles allows technicians to precisely control the final aesthetic outcome, balancing strength with the desired level of translucency for anterior and posterior cases.

Guaranteed Biocompatibility

Once fully sintered, zirconia is a chemically inert and highly biocompatible material. The furnace ensures the material reaches a complete state of densification, eliminating any residual unreacted components and producing a restoration that is safe for long-term placement in the oral cavity.

The Operational Advantage: Efficiency and Consistency

Beyond the quality of the final product, a modern zirconia furnace provides significant operational benefits for a dental laboratory.

Boosting Throughput with Speed and Efficiency

Modern furnaces feature advanced heating elements and superior insulation. This allows for faster heating and cooling cycles, significantly reducing total processing time and enabling labs to increase their daily production capacity.

Eliminating Guesswork for Reproducible Results

By automating and precisely controlling the sintering cycle, the furnace removes process variability. This guarantees consistent and reproducible results for every unit, ensuring that each restoration meets the same high standard of quality.

Versatility Across Zirconia Brands

Different zirconia manufacturers have specific recommended sintering protocols. A programmable furnace offers the versatility to store multiple programs, allowing labs to easily switch between different materials without compromising the outcome of any.

Understanding the Trade-offs and Considerations

While the benefits are clear, achieving them requires a proper understanding of the equipment and process.

The Myth of "Set and Forget"

A high-quality furnace is a precision tool, not a simple appliance. It requires correct programming based on the specific zirconia being used, as well as routine calibration and maintenance to ensure long-term accuracy and reliable performance.

Not All Furnaces Are Created Equal

Furnaces differ in chamber size, maximum temperature, and the speed of their sintering cycles. A "speed" cycle that is poorly controlled can compromise aesthetics or even strength. The quality of the heating elements (typically silicon carbide or molybdenum disilicide) also dictates longevity and temperature stability.

The Importance of Manufacturer Protocols

Deviating from the zirconia manufacturer's validated sintering schedule is a significant risk. Doing so can lead to suboptimal strength, poor aesthetics, or internal stresses that result in premature failure. The furnace's role is to execute these protocols with the highest possible fidelity.

Making the Right Choice for Your Goal

The ideal furnace depends entirely on your laboratory's specific operational needs and clinical goals.

- If your primary focus is high-volume production: Choose a furnace with a large chamber capacity and validated rapid sintering cycles to maximize daily throughput.

- If your primary focus is high-end aesthetic restorations: Prioritize a furnace with highly programmable, multi-stage cycles that offer precise control over heating and cooling rates to fine-tune translucency.

- If your primary focus is reliability and consistency for a general practice: A robust furnace from a reputable brand with proven standard cycles will deliver excellent, predictable results and a strong return on investment.

Ultimately, investing in the right zirconia sintering furnace empowers you to control the final outcome, turning a simple milled shape into a high-performance clinical solution.

Summary Table:

| Benefit | Description |

|---|---|

| Unmatched Strength | Produces zirconia restorations with strength exceeding 1200 MPa, resistant to chipping and fracture. |

| Superior Aesthetics | Enables precise control of translucency and color for natural-looking anterior and posterior restorations. |

| Biocompatibility | Ensures chemically inert, safe restorations through complete densification. |

| Efficiency and Consistency | Automates sintering cycles for reproducible results and increased lab throughput. |

| Versatility | Supports multiple zirconia brands with programmable protocols for diverse material needs. |

Ready to elevate your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to precisely meet your unique sintering requirements, ensuring superior strength, aesthetics, and efficiency for your zirconia restorations. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab