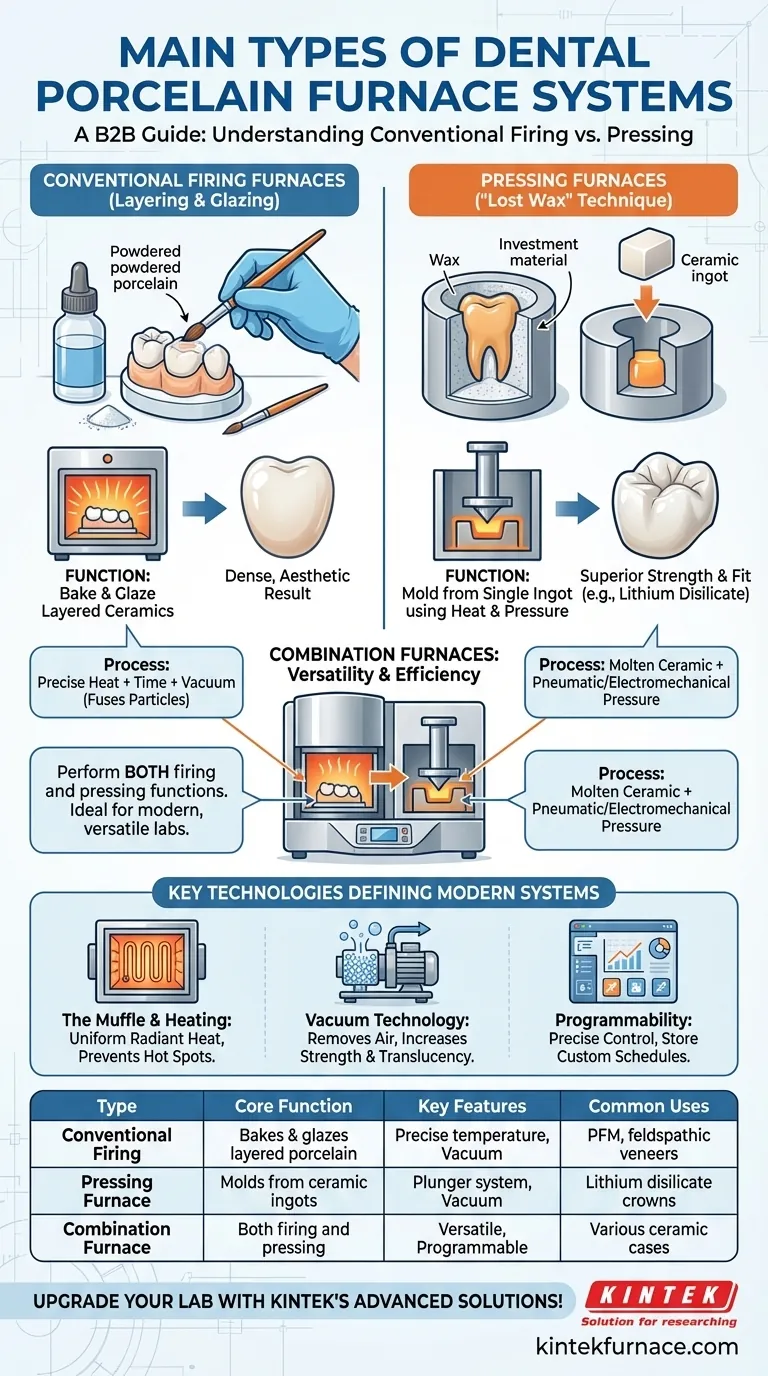

In simple terms, the two primary types of dental porcelain furnaces are distinguished by their core function: conventional firing furnaces and pressing furnaces. A conventional furnace is used to bake and glaze ceramics that have been layered by a technician, while a pressing furnace uses both heat and pressure to mold a restoration from a single ceramic ingot. Many modern units are combination furnaces capable of performing both functions.

The most critical distinction between dental furnace systems is not the heating element, but the process they perform. Your choice depends entirely on whether you need to simply fire layered porcelain or press molten ceramic into a mold—a decision driven by the materials you use.

Understanding the Core Function: Firing vs. Pressing

The classification of a dental furnace is best understood by the job it needs to do. While features like vacuum pumps and digital programming are now standard, the fundamental mechanical difference lies in the ability to press material.

Conventional Firing Furnaces (Layering and Glazing)

The traditional method of creating a porcelain restoration involves a technician meticulously building its shape and color using layers of porcelain powder mixed with a liquid.

The conventional firing furnace is the oven for this process. Its sole job is to heat the layered restoration according to a precise temperature and time schedule. This process, often performed in a vacuum, fuses the ceramic particles together to create a dense, strong, and aesthetic result. These furnaces are also used for the final glazing step to create a smooth, life-like surface.

Pressing Furnaces (The "Lost Wax" Technique for Ceramics)

Pressable ceramics, such as lithium disilicate, require a different approach that provides superior strength and fit. This process involves creating a wax model of the final restoration, which is then encased in an investment material to create a mold.

A pressing furnace handles the subsequent steps. After the wax is burned out of the mold, the furnace heats a solid ceramic ingot until it becomes molten. The furnace then uses an integrated pneumatic or electromechanical plunger to press the molten ceramic into the mold cavity. This combination of heat and pressure creates an incredibly dense and accurately fitting restoration.

The Rise of Combination Furnaces

To maximize versatility and efficiency, most leading manufacturers now produce combination furnaces. These units operate as high-quality conventional firing furnaces but also include a pressing mechanism. This allows a dental lab to perform both traditional layering techniques and modern pressing procedures with a single piece of equipment, making them the most common choice for new labs.

Key Technologies That Define a Modern Furnace

Beyond the core function, several key features are critical for achieving consistent, high-quality results. These are not types of furnaces, but essential components of any professional-grade system.

The Muffle and Heating Element

The heart of the furnace is the muffle, which is the heating chamber. Modern furnaces use a quartz-wrapped heating element that provides indirect, radiant heat. This design ensures extremely uniform heat distribution throughout the chamber, preventing hot spots and ensuring the entire restoration is fired evenly.

Vacuum Technology

Firing porcelain in a vacuum is essential. As the furnace heats up, a pump removes air from the muffle. This prevents oxygen from getting trapped between the ceramic particles, which would otherwise create bubbles and porosity. A restoration fired under vacuum is significantly stronger, denser, and more translucent.

Programmability and Precision Control

Modern furnaces are digitally controlled and fully programmable. This allows technicians to create and store custom firing schedules for the specific materials they use, as different ceramics (e.g., feldspathic vs. lithium disilicate) have unique temperature requirements. High-end furnaces maintain temperature accuracy within +/- 1°C, a level of precision that is non-negotiable for predictable outcomes.

Understanding the Trade-offs

Choosing the right furnace requires balancing capability with cost and workflow. Your decision is directly tied to the types of restorations your lab produces.

Cost vs. Versatility

A furnace designed only for conventional firing is the most basic and cost-effective option. A pressing furnace, due to its additional mechanical plunger system and more complex engineering, represents a higher initial investment. Combination furnaces, while the most expensive, offer the greatest long-term value and versatility.

Material Compatibility Is Mandatory

Your choice of furnace is dictated by your choice of materials. If your lab plans to work with pressable ceramics like leucite-reinforced glass or lithium disilicate (a market standard for high-strength crowns), then a pressing furnace is mandatory. You simply cannot process these materials in a conventional firing-only unit.

Calibration and Maintenance

A porcelain furnace is a precision instrument, not just an oven. Regular temperature calibration is critical. An inaccurate furnace can under-fire restorations, leaving them weak, or over-fire them, causing a poor fit, slumping, and incorrect shades. Consistent maintenance ensures consistent clinical results.

Making the Right Choice for Your Lab

Selecting the correct furnace system is a strategic decision. Base your choice on the services you offer today and your goals for the future.

- If your primary focus is traditional layered restorations (PFM or feldspathic veneers): A high-quality conventional firing furnace with precise programming and a reliable vacuum system is a sufficient and cost-effective solution.

- If your primary focus is high-strength, monolithic restorations (e.g., lithium disilicate crowns): A dedicated or combination pressing furnace is absolutely essential to your workflow.

- If you are equipping a versatile lab or planning for future growth: A combination firing and pressing furnace is the wisest investment, providing maximum flexibility to handle any ceramic case that comes your way.

Understanding these functional differences empowers you to invest in equipment that directly supports your lab's quality, efficiency, and profitability.

Summary Table:

| Type | Core Function | Key Features | Common Uses |

|---|---|---|---|

| Conventional Firing Furnace | Bakes and glazes layered porcelain | Precise temperature control, vacuum technology | Traditional layered restorations (e.g., PFM, feldspathic veneers) |

| Pressing Furnace | Molds restorations from ceramic ingots using heat and pressure | Pneumatic/electromechanical plunger, vacuum system | High-strength monolithic restorations (e.g., lithium disilicate crowns) |

| Combination Furnace | Performs both firing and pressing functions | Versatile, programmable, includes pressing mechanism | Labs requiring flexibility for various ceramic cases |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, enhancing efficiency and quality. Contact us today to discuss how our furnaces can support your lab's growth and profitability!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures