At its core, a zirconia sintering furnace provides the critical final step in fabricating modern dental restorations. These specialized ovens are not merely for heating; they are precision instruments designed to transform a fragile, milled zirconia framework into a final product with exceptional strength, predictable aesthetics, and clinical reliability. The primary advantages lie in their ability to ensure uniform sintering through precise temperature control, which directly enhances restoration quality and lab productivity.

The crucial advantage of a zirconia sintering furnace is its ability to create a highly controlled, extreme-temperature environment. This precision is what unlocks the full clinical potential of zirconia, ensuring the material achieves its maximum strength and desired translucency while streamlining the laboratory's workflow.

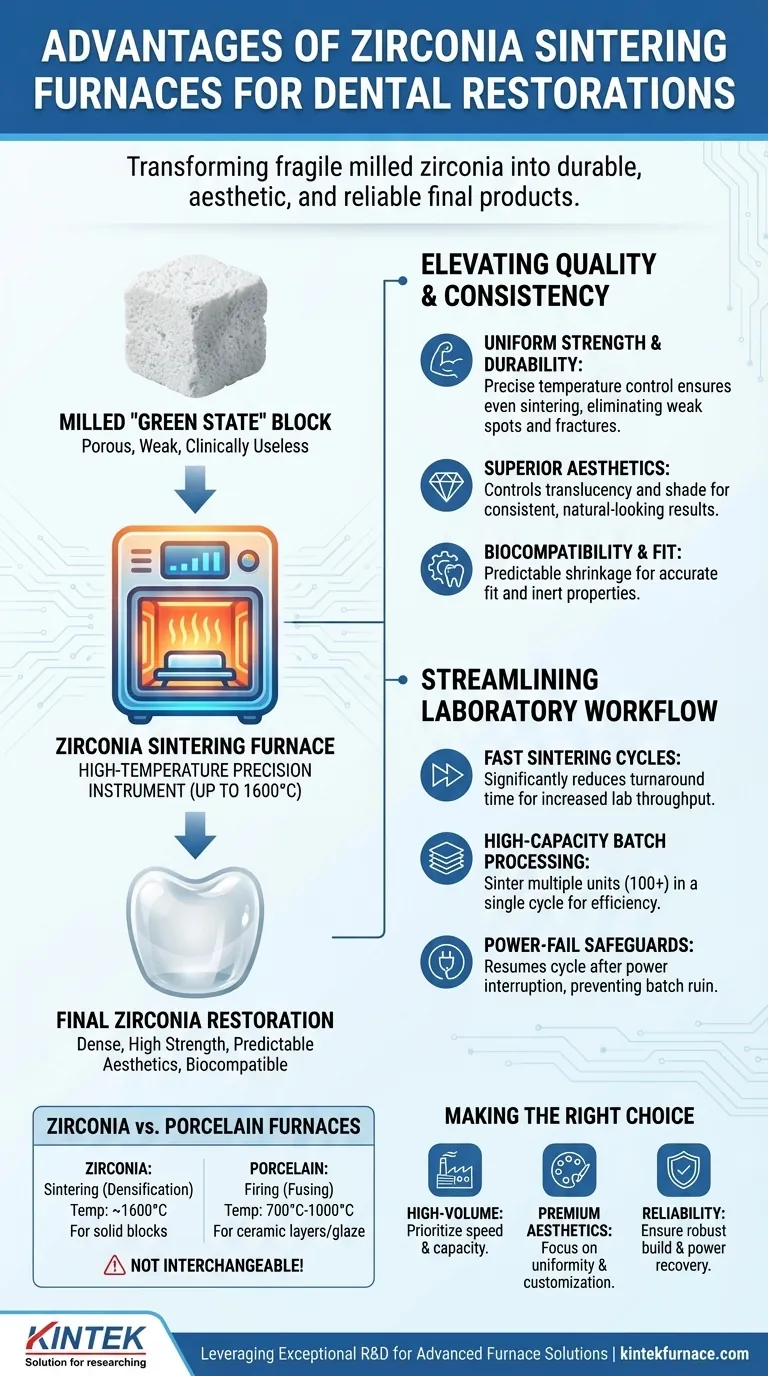

The Foundation: From Milled Block to Final Restoration

A zirconia sintering furnace is responsible for the densification process that gives a restoration its final properties. Without it, the milled material remains in a porous, chalk-like "green state" and is clinically useless.

What is Sintering?

Sintering is a thermal process that fuses the zirconia particles together, eliminating the porosity of the milled block. This process shrinks the restoration to its final, dense dimensions, giving it immense strength.

Why Zirconia Requires a Specialized Furnace

Zirconia demands a very specific and challenging environment to sinter correctly. It requires extremely high temperatures, often up to 1600°C, and prolonged holding times to achieve full densification and biocompatibility. A dedicated zirconia furnace is built to reliably reach and maintain these conditions.

Elevating Restoration Quality and Consistency

The ultimate goal of any dental lab is to produce consistent, high-quality restorations. A modern sintering furnace is central to achieving this by removing process variables.

Achieving Uniform Strength and Durability

The most critical function of the furnace is its precise and uniform temperature control. Even small temperature deviations can create internal stresses or incomplete sintering, leading to weak spots and potential fractures. Advanced heating elements ensure the entire restoration sinters evenly, resulting in predictable, robust strength.

Unlocking Superior Aesthetics

Sintering doesn't just affect strength; it's also crucial for aesthetics. The temperature and duration of the sintering cycle directly influence the material's final translucency and shade. Precise control allows technicians to consistently produce restorations that meet the high aesthetic demands of patients.

Ensuring Biocompatibility and Fit

Proper sintering transforms the zirconia into a dense, inert ceramic, ensuring it is fully biocompatible for use in the mouth. This controlled shrinkage is also highly predictable, resulting in restorations that fit the preparation accurately with minimal adjustment.

Streamlining Laboratory Workflow and Productivity

Beyond quality, a furnace must support an efficient and profitable workflow. Modern features are designed specifically to increase throughput and reduce costly downtime.

The Impact of Fast Sintering Cycles

Many contemporary furnaces offer fast sintering programs that can significantly reduce the hours-long process. This dramatically shortens the turnaround time for crowns and bridges, allowing labs to complete more cases per day.

High-Capacity and Batch Processing

Efficiency is gained through volume. Furnaces designed with large chambers and the ability to stack multiple crucibles allow technicians to sinter many units—sometimes over 100 at once—in a single cycle.

Enhancing Reliability with Power-Fail Safeguards

A power outage during a long sintering cycle can ruin an entire batch of restorations, costing significant time and money. The power interruption recovery feature is a critical safeguard, allowing the furnace to resume the cycle exactly where it left off once power is restored.

Understanding the Key Distinction: Zirconia vs. Porcelain Furnaces

It is crucial to understand that these are not interchangeable tools. While both are furnaces used in a dental lab, their purpose, technology, and temperature capabilities are fundamentally different.

Different Materials, Different Processes

Zirconia furnaces are designed for sintering—the high-heat densification of a solid block. Porcelain furnaces are designed for firing—fusing layers of ceramic powder or applying a final glaze at much lower temperatures.

Temperature and Cycle Requirements

Zirconia requires sustained temperatures that can approach 1600°C. Porcelain furnaces, by contrast, typically operate in the 700°C to 1000°C range. Using the wrong furnace would result in complete failure of the restoration.

Investment and Specialization

A zirconia sintering furnace is a specialized investment dedicated to a specific high-performance material. Its construction and heating elements are engineered to withstand extreme thermal demands over the long term, making it a durable and reliable cornerstone of the modern digital dental workflow.

Making the Right Choice for Your Lab

Selecting a furnace should be guided by the specific goals and workflow of your laboratory.

- If your primary focus is high-volume production: Prioritize furnaces with high capacity, crucible stacking capabilities, and proven fast-sintering programs.

- If your primary focus is premium aesthetic restorations: Look for furnaces with exceptional temperature uniformity and highly customizable programs to precisely control translucency.

- If your primary focus is reliability and minimizing downtime: Features like robust heating elements and power interruption recovery are non-negotiable investments.

Choosing the right sintering furnace is a direct investment in the quality, consistency, and efficiency of every zirconia restoration you produce.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precise Temperature Control | Ensures uniform sintering for maximum strength and durability |

| Enhanced Aesthetics | Allows consistent translucency and shade control |

| Biocompatibility and Fit | Achieves accurate fit and inert properties for safety |

| Fast Sintering Cycles | Reduces turnaround time, increasing lab productivity |

| High-Capacity Processing | Enables batch sintering of multiple units for efficiency |

| Power Interruption Recovery | Safeguards against cycle failures, minimizing downtime |

Ready to elevate your dental lab's performance with precision sintering solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you focus on high-volume production, premium aesthetics, or reliability, our furnaces deliver enhanced strength, consistency, and efficiency for your zirconia restorations. Contact us today to discuss how we can tailor a solution for your needs!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations