The primary advantages of a porcelain furnace are its ability to produce highly aesthetic, durable, and precisely fitted dental restorations with unparalleled consistency. By giving the dental technician complete control over the firing process, these devices are essential for transforming ceramic materials into restorations that mimic the function and appearance of natural teeth.

The true value of a porcelain furnace isn't just heating ceramic; it's the precise manipulation of temperature and atmosphere. This control is what allows a technician to unlock a material's full potential for both strength and aesthetics, directly impacting clinical success and patient satisfaction.

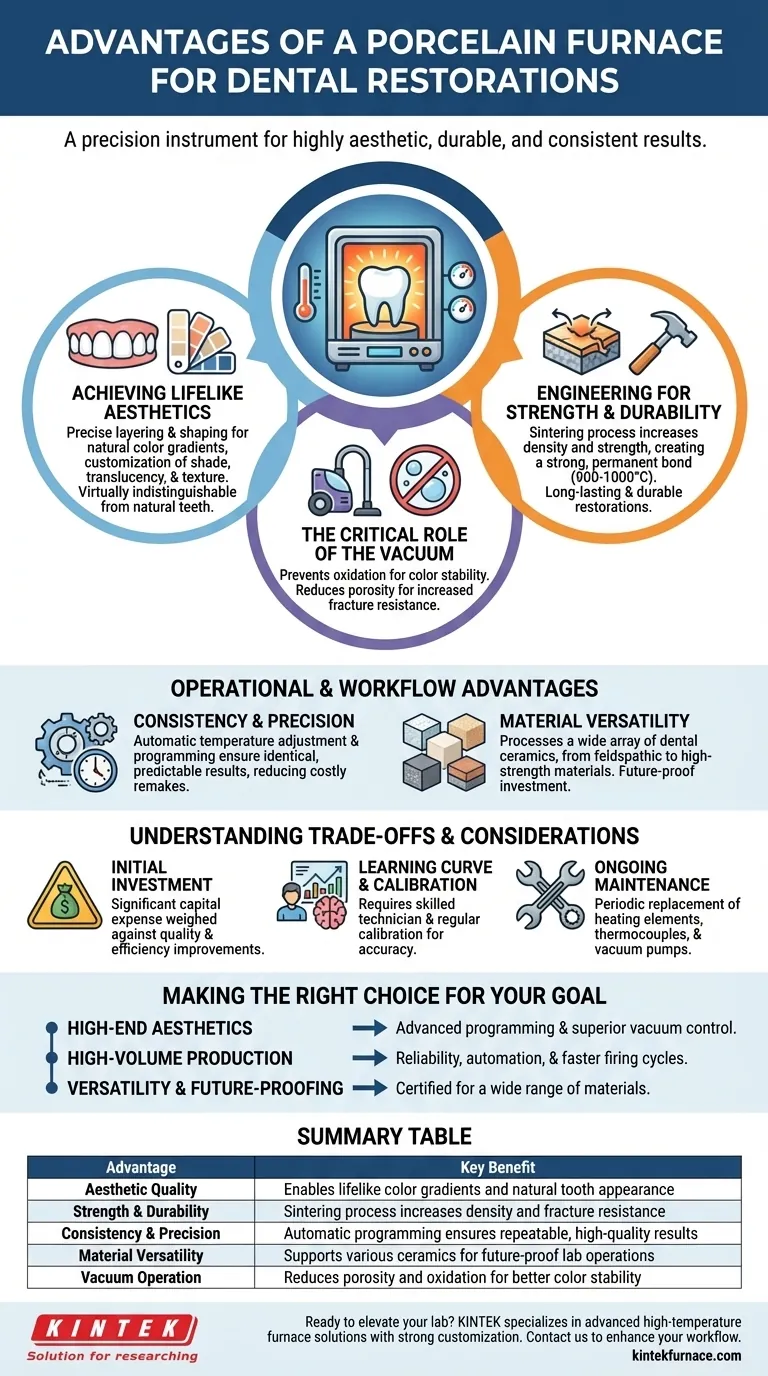

The Foundation of Control: How a Furnace Creates Superior Restorations

A porcelain furnace is not merely an oven. It is a precision instrument designed to execute complex firing programs that dictate the final properties of a dental ceramic.

Achieving Lifelike Aesthetics

A key advantage is the ability to create restorations that are virtually indistinguishable from natural teeth. A furnace enables the precise layering and shaping of ceramics to build up natural-looking color gradients and internal characterization.

Modern furnaces allow for the complete customization of shade, translucency, and surface texture. This ensures the final crown or veneer blends seamlessly with the patient's existing dentition.

Engineering for Strength and Durability

The furnace executes a process called sintering, where ceramic particles are heated until they fuse together. This significantly increases the material's density and strength, resulting in a long-lasting and durable restoration.

By precisely managing temperatures, often between 900-1000°C, the furnace creates a strong, permanent bond between the porcelain and its underlying substrate without causing cracks or internal stress.

The Critical Role of the Vacuum

Most advanced furnaces operate under a vacuum. Removing air from the firing chamber prevents oxidation, which can discolor the ceramic and compromise its appearance.

The vacuum environment also dramatically reduces porosity in the final restoration. A less porous ceramic is not only stronger and more fracture-resistant but also has improved color stability over time.

Operational and Workflow Advantages

Beyond the quality of the final product, porcelain furnaces offer significant benefits to the dental laboratory's workflow and efficiency.

Ensuring Consistency and Precision

Modern furnaces feature automatic temperature adjustment and sophisticated programming. This guarantees that every firing cycle is identical, leading to highly consistent and predictable results, which in turn reduces the need for costly remakes.

Features like a precision stepper motor drive can ensure noise-free operation, contributing to a better lab environment. An optical status display provides technicians with real-time feedback, allowing for immediate process monitoring.

Material Versatility

These furnaces are engineered to be versatile. They can process a wide array of dental ceramics, from traditional feldspathic porcelains to newer, high-strength materials, making them a future-proof investment for a growing lab.

Understanding the Trade-offs and Considerations

While the advantages are clear, a strategic decision requires an objective look at the associated commitments.

The Initial Investment

High-quality porcelain furnaces represent a significant capital expense. The cost must be weighed against the expected improvements in quality, efficiency, and the types of high-value restorations the lab can offer.

The Learning Curve and Calibration

Achieving optimal results is not automatic. It requires a skilled technician who understands the nuances of different ceramic systems and firing parameters.

Furthermore, furnaces require regular calibration to ensure temperature accuracy. An uncalibrated furnace will negate any potential for precision and consistency.

Ongoing Maintenance

A porcelain furnace has components that wear out over time. Heating elements, thermocouples, and vacuum pumps all require periodic maintenance or replacement, which represents an ongoing operational cost.

Making the Right Choice for Your Goal

The right furnace is a strategic asset that should align with your lab's primary objectives.

- If your primary focus is high-end aesthetic cases: Invest in a furnace with advanced programming options and superior vacuum control to master translucency and color.

- If your primary focus is high-volume production: Prioritize models known for their reliability, automation, and faster firing cycles to maximize throughput.

- If your primary focus is versatility and future-proofing: Select a furnace that is certified to process a wide range of materials, including those you plan to adopt in the future.

Ultimately, investing in the right porcelain furnace empowers a dental lab to move beyond simple fabrication and toward the consistent creation of exceptional restorations.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Aesthetic Quality | Enables lifelike color gradients and natural tooth appearance |

| Strength and Durability | Sintering process increases density and fracture resistance |

| Consistency and Precision | Automatic programming ensures repeatable, high-quality results |

| Material Versatility | Supports various ceramics for future-proof lab operations |

| Vacuum Operation | Reduces porosity and oxidation for better color stability |

Ready to elevate your dental lab's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for dental laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, and Vacuum & Atmosphere Furnaces, with strong deep customization to meet your unique needs for precise, aesthetic restorations. Contact us today to discuss how our furnaces can enhance your workflow and deliver superior patient outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations