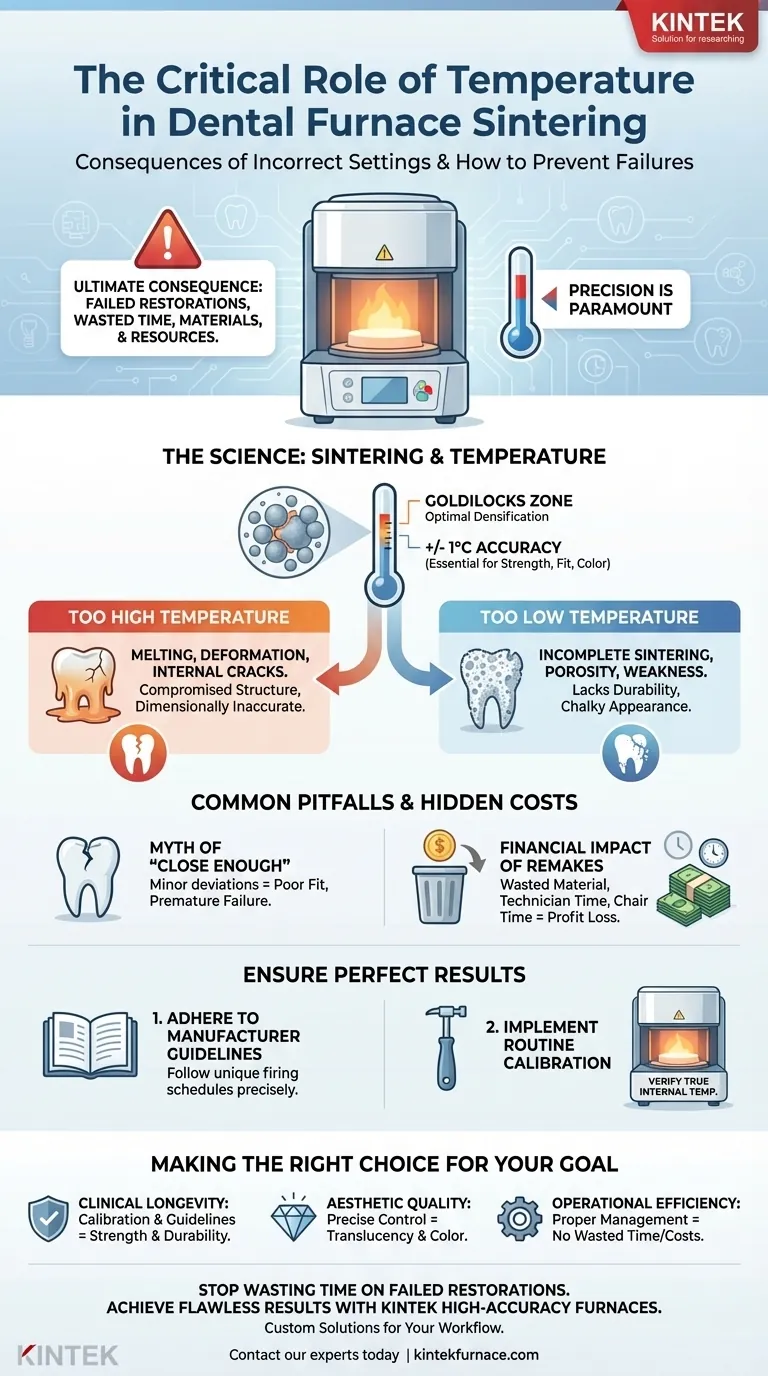

Ultimately, using incorrect temperature settings in a dental furnace leads to failed restorations, wasting valuable time, materials, and clinical resources. A temperature that is too high can cause the material to melt, deform, or crack, while a temperature that is too low results in incomplete sintering, creating a weak and porous final product.

The core issue is that precise temperature control is not merely a procedural step but the fundamental factor governing the structural integrity and aesthetic quality of a dental restoration. Even minor deviations from the correct thermal profile can render the final product clinically unusable.

The Science of Sintering and Temperature

Sintering is the process of fusing particles of a material like zirconia together using heat, just below its melting point, to form a solid, dense object. Temperature is the primary engine driving this transformation, and its accuracy is paramount.

The Narrow Window for Success

Every dental ceramic has a specific, narrow temperature range—a "Goldilocks zone"—where optimal densification occurs. This precise temperature allows the material's particles to bond correctly without losing their structural form.

The Role of Accurate Control

Modern furnaces often feature high accuracy, aiming for a tolerance of +/- 1°C. This level of precision is not a luxury; it is a necessity. Consistent and accurate firing temperatures are directly responsible for the final restoration's strength, fit, and color.

Consequences of Temperature Errors

Getting the temperature wrong is not a minor issue; it causes catastrophic failure in the material at a microscopic level. These failures manifest in two distinct ways depending on the direction of the error.

When the Temperature is Too High

Setting the furnace temperature above the recommended range causes the material to overheat. This can lead to melting, deformation, or the development of internal cracks. The crystalline structure is compromised, resulting in a restoration that is dimensionally inaccurate and prone to fracture.

When the Temperature is Too Low

Conversely, a temperature that is too low prevents the sintering process from completing. This results in a restoration that is porous and weak, as the material particles have not fully fused. The final product will lack durability and may appear chalky or opaque.

Common Pitfalls and Hidden Costs

Beyond the immediate material failure, incorrect temperature settings carry significant operational consequences. Understanding these hidden costs emphasizes the importance of getting it right every time.

The Myth of "Close Enough"

A common pitfall is assuming that a small temperature deviation of a few degrees is acceptable. However, even minor variations can significantly impact the material's physical properties, leading to a poor marginal fit or premature failure of the restoration in the patient's mouth.

The Financial Impact of Remakes

Every failed restoration represents a direct financial loss. This includes the cost of the wasted material, the technician's time, and the valuable chair time lost for both the clinician and the patient. These costs accumulate quickly and impact a lab's or clinic's profitability.

How to Ensure Perfect Results

Preventing temperature-related failures relies on a two-part strategy of following established protocols and verifying your equipment's accuracy.

Adhere to Manufacturer Guidelines

The single most important step is to always consult and follow the manufacturer's guidelines. Every dental material has a unique firing schedule that has been extensively tested. Deviating from these instructions is a direct path to failure.

Implement Routine Furnace Calibration

The temperature displayed on your furnace is not always the true internal temperature. It is crucial to routinely calibrate the furnace to ensure its readings are accurate. This verification process confirms that the temperature you set is the temperature the restoration is actually receiving.

Making the Right Choice for Your Goal

- If your primary focus is clinical longevity: Treat furnace calibration and adherence to material guidelines as non-negotiable steps to guarantee restoration strength and durability.

- If your primary focus is aesthetic quality: Understand that precise temperature control is what dictates the final translucency and color, making accuracy essential for high-end results.

- If your primary focus is operational efficiency: View proper temperature management as your best defense against the wasted time, materials, and costs associated with remakes.

Mastering temperature control is the foundation for producing consistent, reliable, and high-quality dental restorations.

Summary Table:

| Temperature Error | Consequence on Restoration |

|---|---|

| Too High | Melting, deformation, internal cracks, dimensional inaccuracy |

| Too Low | Incomplete sintering, porosity, weakness, chalky appearance |

Stop wasting time and materials on failed restorations. Precise temperature control is non-negotiable for strong, aesthetically perfect dental work. Backed by expert R&D and manufacturing, KINTEK offers high-accuracy dental furnaces with the precise control your lab needs. Our solutions are customizable to fit your unique workflows and material requirements.

Contact our experts today to discuss how we can help you achieve flawless results and boost your lab's efficiency.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique