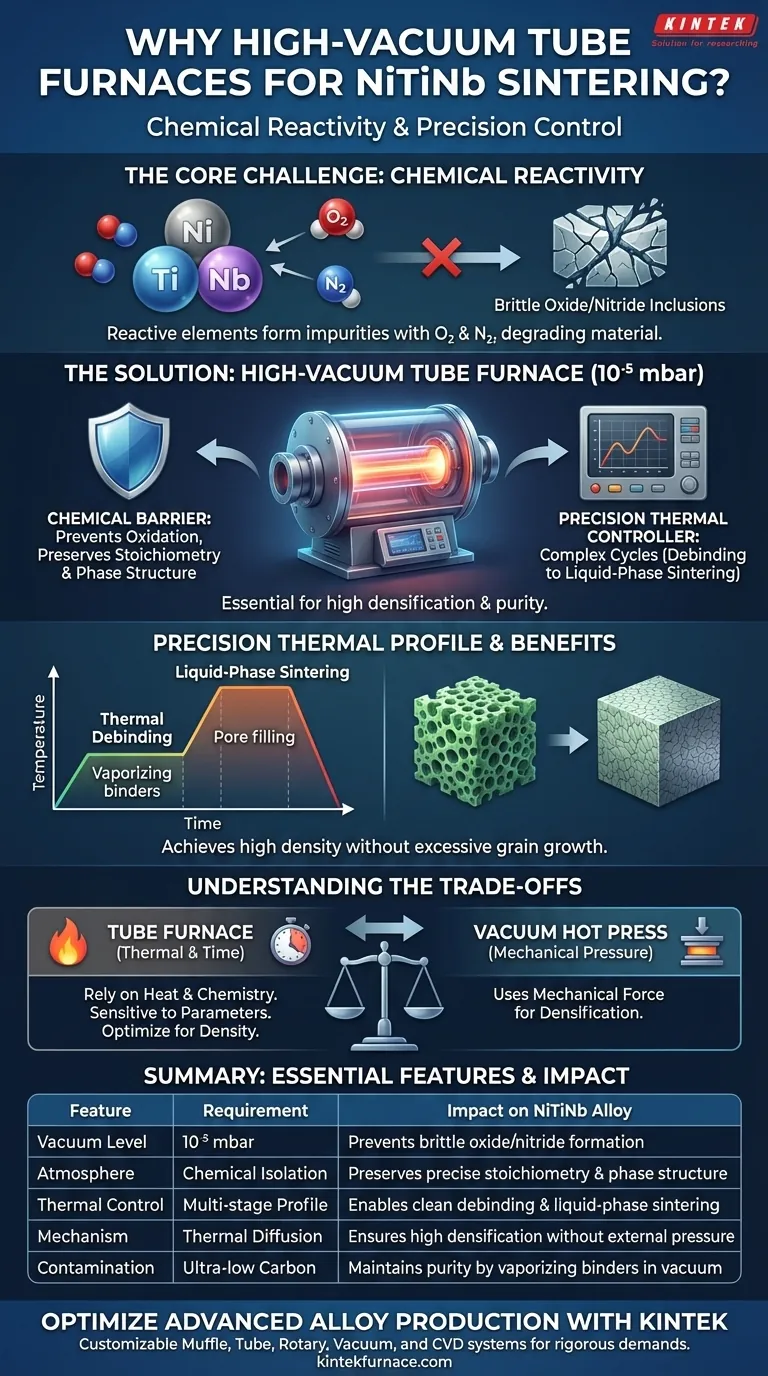

Chemical reactivity dictates the process. The final sintering of NiTiNb alloys must occur in a high-vacuum tube furnace because Nickel, Titanium, and Niobium are extremely reactive with oxygen and nitrogen at high temperatures. A high-vacuum environment (typically 10⁻⁵ mbar) is essential to prevent the formation of oxide impurities that would degrade the material, while simultaneously allowing for precise control over complex thermal cycles ranging from debinding to liquid-phase sintering.

The high-vacuum tube furnace serves a dual purpose: it acts as a chemical barrier against oxidation and a precision thermal controller. This environment is non-negotiable for achieving the high densification, chemical purity, and specific microscopic phase structure required for the alloy's shape memory performance.

The Critical Necessity of Chemical Isolation

The primary challenge in processing NiTiNb is the inherent instability of its constituent elements when exposed to air at sintering temperatures.

Preventing Elemental Contamination

Nickel (Ni), Titanium (Ti), and Niobium (Nb) are highly active elements. When heated, they react aggressively with oxygen and nitrogen.

If these reactions occur, they form brittle oxide or nitride inclusions. By maintaining an extremely low oxygen partial pressure (e.g., 10⁻⁵ mbar), the high-vacuum tube furnace effectively inhibits these impurities, preserving the alloy's theoretical composition.

Preserving Stoichiometry

The functional properties of shape memory alloys rely on precise chemical stoichiometry.

Even minor oxidation can alter the ratio of Ti to Ni/Nb, which shifts the phase transformation temperatures. Vacuum sintering ensures that the final chemical composition matches the intended design, maintaining the integrity of the microscopic phase structure.

Precision Control of the Thermal Profile

Beyond protection, the tube furnace facilitates complex, multi-stage heat treatments that are difficult to execute in other equipment.

Integrated Thermal Debinding

Before final sintering, the "green" part often contains binding agents that must be removed.

The tube furnace can execute a low-temperature thermal debinding stage to vaporize these residuals. Doing this in a controlled vacuum prevents carbon contamination from the binder, which could otherwise compromise the alloy's purity.

Facilitating Liquid-Phase Sintering

Achieving high density in NiTiNb often requires liquid-phase sintering.

This process involves heating the material to a point where a portion of the alloy melts, filling voids between particles. The precise temperature control of the tube furnace ensures high densification is achieved without causing excessive grain growth or distortion.

Understanding the Trade-offs

While the high-vacuum tube furnace is the standard for purity, relying solely on thermal mechanisms for densification presents specific challenges compared to pressure-assisted methods.

Reliance on Thermal Mechanisms

Unlike a vacuum hot press, which uses mechanical force (e.g., 25 MPa) to physically crush pores, a tube furnace relies entirely on temperature and time.

If the liquid-phase sintering profile is not perfectly optimized, you risk residual porosity. You cannot rely on external pressure to force particle rearrangement; the chemistry and heat must do all the work.

Sensitivity to Process Parameters

The window for success in a tube furnace is narrow.

Because there is no mechanical pressure to assist diffusion, the activation energy for atomic diffusion must be provided entirely by heat. Slight deviations in the temperature profile can lead to under-sintering (low density) or over-sintering (loss of dimensional accuracy).

Making the Right Choice for Your Goal

To maximize the effectiveness of a high-vacuum tube furnace for NiTiNb, tailor your parameters to your specific outcome.

- If your primary focus is Chemical Purity: Ensure your vacuum system can reliably maintain pressures of 10⁻⁵ mbar or better throughout the entire heating cycle to prevent Ti/Nb oxidation.

- If your primary focus is High Density: Optimize your liquid-phase sintering profile to ensure sufficient atomic diffusion and pore filling, as you cannot rely on mechanical pressure to close voids.

The high-vacuum tube furnace is not merely a heating device; it is a chemical isolation chamber essential for unlocking the functional potential of NiTiNb alloys.

Summary Table:

| Feature | Requirement | Impact on NiTiNb Alloy |

|---|---|---|

| Vacuum Level | 10⁻⁵ mbar | Prevents brittle oxide/nitride formation |

| Atmosphere | Chemical Isolation | Preserves precise stoichiometry & phase structure |

| Thermal Control | Multi-stage Profile | Enables clean debinding & liquid-phase sintering |

| Mechanism | Thermal Diffusion | Ensures high densification without external pressure |

| Contamination | Ultra-low Carbon | Maintains purity by vaporizing binders in vacuum |

Optimize Your Advanced Alloy Production with KINTEK

Precision in NiTiNb sintering starts with the right environment. KINTEK provides high-performance high-vacuum tube furnaces specifically designed to meet the rigorous demands of reactive metal processing. Backed by expert R&D and world-class manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique laboratory or industrial needs.

Don't compromise on chemical purity or material densification. Contact our technical specialists today to discover how our high-temperature solutions can enhance your material science outcomes and streamline your thermal workflows.

Visual Guide

References

- N. Abando Beldarrain, Ralph Spolenak. Micromechanical Insights into Sinter‐Based Additively Manufactured NiTi with Nb as a Sintering Aid. DOI: 10.1002/adem.202501243

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What conditions does a tube furnace provide for the carbonization of aerogels? Master Precision Thermal Control

- What makes tubular furnaces versatile? Unlock Precision in Material Processing

- What role does a high-temperature tube furnace play in the post-processing of high-entropy alloys? Optimize Microstructure

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- How does a tube furnace ensure a controlled reaction environment? Achieve Precise Isothermal Oxidation Results

- Why is calibration important for a horizontal electric furnace? Ensure Precise Temperature Control for Your Materials

- What are the different designs of High Temperature Tube Furnaces? Choose the Right Design for Your Lab

- What are the primary benefits of using a split tube furnace? Enhance Lab Efficiency with Unmatched Flexibility