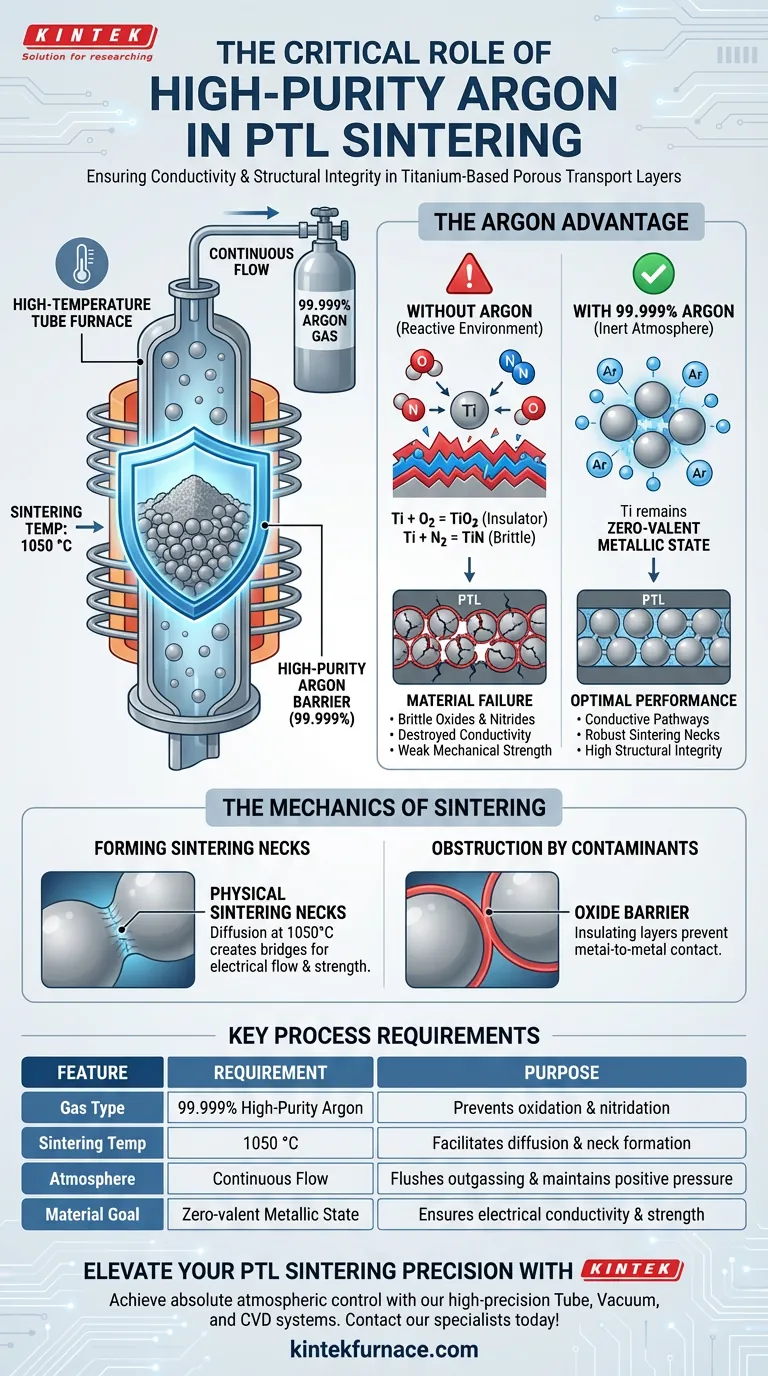

High-purity argon gas serves as a critical chemical isolation barrier. In the sintering of Porous Transport Layers (PTL), the argon atmosphere prevents the titanium powder from reacting with environmental oxygen and nitrogen. Without this 99.999% pure shield, the high temperatures required for sintering would cause the titanium to form brittle oxides, destroying the material's conductivity and mechanical strength.

Core Takeaway Titanium-based PTLs require a sintering temperature of 1050 °C to fuse powder particles effectively. A continuous flow of high-purity argon is the only way to facilitate the formation of physical sintering necks while preventing chemical degradation, ensuring the final product remains conductive and structurally sound.

The Chemical Necessity of Inert Atmospheres

Titanium's High-Temperature Reactivity

The primary material in many Porous Transport Layers is titanium metal. While stable at room temperature, titanium becomes highly chemically reactive at elevated temperatures.

Preventing Oxide Formation

If exposed to air during the heating process, titanium essentially combusts or corrodes rapidly. It reacts with oxygen to form oxides and with nitrogen to form nitrides.

The Role of 99.999% Purity

Standard industrial argon is often insufficient for this process. The process specifically demands 99.999% pure argon to ensure the complete isolation of the metal from even trace amounts of reactive gases.

The Mechanics of Sintering

Forming Physical Sintering Necks

The goal of sintering at 1050 °C is to induce diffusion between titanium powder particles. This creates "necks"—physical bridges where the particles fuse together.

Obstruction by Contaminants

If oxygen is present, an oxide layer forms on the surface of the particles. This layer acts as a barrier, preventing the metal-to-metal contact necessary for these sintering necks to form.

Preserving Metallic Conductivity

A Porous Transport Layer must conduct electricity to function in electrochemical applications. Titanium oxides are electrical insulators. By maintaining the zero-valent metallic state of the titanium, argon ensures the final component remains conductive.

Understanding the Trade-offs and Risks

The Cost of Purity vs. Material Failure

Using ultra-high-purity argon increases operational costs compared to lower-grade gases. However, compromising on gas purity leads to irreversible material degradation, resulting in a brittle PTL that creates high electrical resistance.

Flow Rate and Atmosphere Control

It is not enough to simply fill the furnace once. A continuous flow is required to flush out any outgassing from the furnace components and maintain positive pressure, preventing outside air from leaking in.

Making the Right Choice for Your Goal

To ensure the success of your PTL sintering process, consider the following priorities:

- If your primary focus is Electrical Conductivity: Ensure your argon source is certified 99.999% pure to prevent the formation of insulating oxide layers on the titanium particles.

- If your primary focus is Mechanical Structural Integrity: Verify that your furnace maintains a consistent positive pressure of argon to ensure robust sintering necks form at 1050 °C without brittle inclusions.

A strictly controlled, high-purity argon atmosphere is not an optional variable; it is the fundamental enabler of titanium sintering.

Summary Table:

| Feature | Requirement for PTL Sintering | Purpose in Process |

|---|---|---|

| Gas Type | 99.999% High-Purity Argon | Prevents titanium oxidation and nitridation |

| Sintering Temp | 1050 °C | Facilitates diffusion and sintering neck formation |

| Atmosphere | Continuous Flow | Flushes outgassing and maintains positive pressure |

| Material Goal | Zero-valent Metallic State | Ensures electrical conductivity and mechanical strength |

Elevate Your PTL Sintering Precision with KINTEK

Don't let trace contaminants ruin your high-performance materials. At KINTEK, we understand that Porous Transport Layer (PTL) production requires absolute atmospheric control.

Backed by expert R&D and world-class manufacturing, we provide high-precision Tube, Vacuum, and CVD systems specifically designed for titanium sintering and inert gas processing. Our customizable lab high-temp furnaces ensure uniform heating and airtight integrity to protect your material's conductivity.

Ready to optimize your sintering results? Contact us today to discuss your unique needs with our technical specialists!

Visual Guide

References

- Jason Keonhag Lee, Michael C. Tucker. Pioneering Microporous Layers for Proton-Exchange-Membrane Water Electrolyzers via Tape Casting. DOI: 10.1149/1945-7111/ad54f1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What kind of experimental environment does a high vacuum tube furnace provide for high-performance ceramic preparation?

- How does a Tube Furnace ensure structural consistency in Fe/MWCNT synthesis? Expert Control for Composite Quality

- What is the specific role of a tube furnace in the synthesis and carbon-encapsulation of NiMo alloys? Explained

- What is the role of a benchtop tube furnace in the preparation of corn stover biochar? Optimize Pyrolysis Precision

- How does a Tube Furnace function in the catalytic pyrolysis process for producing biochar? Enhance Carbonization Quality

- Why is a tube high-temperature furnace required for Au@MoSe2/graphene composites? Precision Reaction Control

- What role does a continuous bench-scale drop tube pyrolyzer play in FPBO? Maximize High-Quality Bio-oil Yields

- How does thermal treatment in a tube furnace improve biomass films? Enhance Heat Management via Graphitization