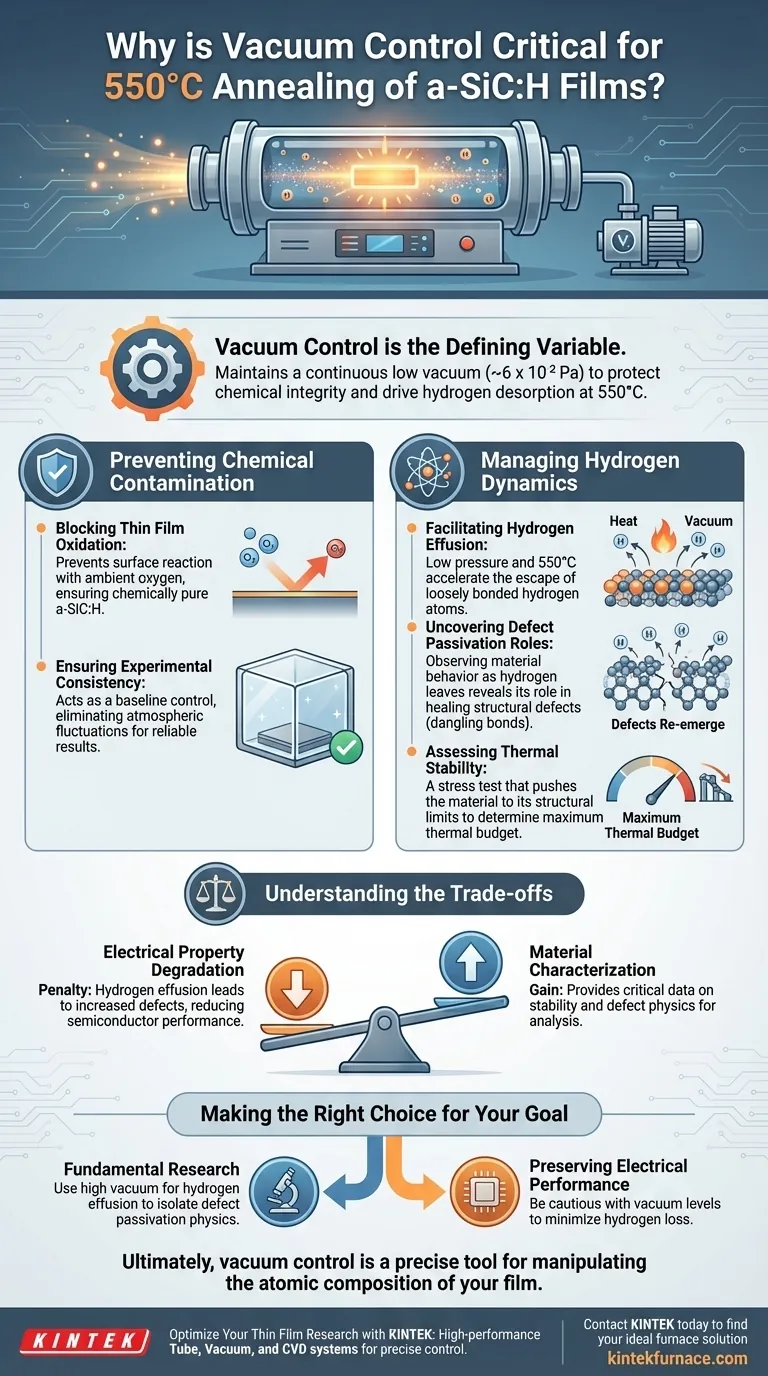

Vacuum control is the defining variable that determines the chemical integrity of hydrogenated amorphous silicon carbide (a-SiC:H) during high-temperature processing. Specifically, when annealing at 550 °C, maintaining a continuous low vacuum (approximately 6 x 10⁻² Pa) is required to prevent immediate surface oxidation while actively driving the desorption of hydrogen to test material stability.

Core Insight: While vacuum annealing protects the film from external contaminants like oxygen, it simultaneously acts as a stress test for the material's internal structure. The process forces hydrogen effusion, which intentionally degrades electrical properties to reveal the material's underlying thermal stability and defect mechanisms.

Preventing Chemical Contamination

Blocking Thin Film Oxidation

At 550 °C, silicon-based materials are highly reactive to oxygen. Without a controlled environment, the film surface would immediately react with ambient air.

A continuous vacuum environment prevents this reaction. By removing oxygen from the chamber, you ensure the film remains chemically pure a-SiC:H rather than forming an unwanted oxide layer.

Ensuring Experimental Consistency

The vacuum acts as a baseline control for the experiment. It eliminates variables related to atmospheric fluctuation.

This allows researchers to attribute any changes in the material strictly to the thermal treatment, rather than interactions with airborne contaminants.

Managing Hydrogen Dynamics

Facilitating Hydrogen Effusion

The vacuum environment lowers the partial pressure surrounding the sample. This physical condition facilitates the "effusion," or escape, of hydrogen atoms from the thin film matrix.

This is a critical mechanism in a-SiC:H films. The hydrogen atoms are loosely bonded, and the combination of high heat (550 °C) and low pressure accelerates their removal.

Uncovering Defect Passivation Roles

Hydrogen in these films typically serves to "passivate" or heal structural defects (dangling bonds).

By using vacuum to strip the hydrogen away, researchers can observe how the material behaves when those defects re-emerge. This highlights the specific role hydrogen plays in maintaining the film's quality.

Assessing Thermal Stability

The vacuum anneal effectively serves as a durability test. By forcing hydrogen out, you are testing the structural limits of the material.

This helps determine the maximum thermal budget the material can withstand before its properties fundamentally collapse.

Understanding the Trade-offs

Electrical Property Degradation

It is vital to recognize that this process comes with a penalty. The primary reference notes that the effusion of hydrogen leads to a degradation of electrical properties.

As hydrogen leaves, defects (dangling bonds) increase, reducing the film's performance as a semiconductor.

Analysis vs. Fabrication

Consequently, this specific vacuum process is often more useful for material characterization than for final device fabrication.

You are sacrificing the immediate performance of the sample to gain data on its stability and defect physics.

Making the Right Choice for Your Goal

To maximize the value of your annealing process, align the vacuum parameters with your specific objective:

- If your primary focus is fundamental research: Use high vacuum to intentionally drive hydrogen effusion; this allows you to isolate and study the physics of defect passivation.

- If your primary focus is preserving electrical performance: Be cautious with vacuum levels and duration at 550 °C, as excessive hydrogen loss will degrade the film's electronic quality.

Ultimately, vacuum control is not just about keeping the furnace clean; it is a precise tool for manipulating the atomic composition of your film.

Summary Table:

| Feature | Impact on a-SiC:H Film at 550 °C |

|---|---|

| Vacuum Level | Prevents surface oxidation and chemical contamination |

| Hydrogen Effusion | Facilitated by low pressure; reveals defect mechanisms |

| Structural Integrity | Tests the thermal budget and structural limits of the film |

| Electrical Properties | May degrade due to loss of hydrogen passivation |

| Primary Application | Material characterization and thermal stability analysis |

Optimize Your Thin Film Research with KINTEK

Precision vacuum control is the difference between a successful experiment and contaminated results. KINTEK provides high-performance Tube, Vacuum, and CVD systems designed to meet the rigorous demands of semiconductor research and material science. Backed by expert R&D and manufacturing, our horizontal tube furnaces offer the stability and atmospheric control necessary for sensitive processes like a-SiC:H annealing.

Whether you need a standard setup or a fully customizable solution tailored to your unique thermal processing needs, our team is ready to help.

Contact KINTEK today to find your ideal furnace solution

Visual Guide

References

- Z. Remeš, Oleg Babčenko. Thin Hydrogenated Amorphous Silicon Carbide Layers with Embedded Ge Nanocrystals. DOI: 10.3390/nano15030176

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What types of reactions can tube furnaces be used for besides synthesis and purification? Explore Versatile Thermal Processing Applications

- What functions does a high-temperature quartz tube furnace perform? Precise Synthesis of Doped Carbon Supports

- What technological requirements affect tube furnace design? Key Factors for Optimal Performance

- What are the benefits of using tube furnaces in industrial processes? Achieve Precision and Control for Your Lab

- How does a Tube Furnace facilitate precise control during CVD? Master Stoichiometry and Phase Purity

- What industries commonly use horizontal furnaces? Unlock High-Temperature Processing for Your Sector

- What is the primary function of high-vacuum quartz tube sealing in Mo2S3 synthesis? Ensure Phase Purity and Precision

- What is the significance of using a vacuum-sealed fused silica tube in Bi2Te3 synthesis? Ensure Purity & Stoichiometry