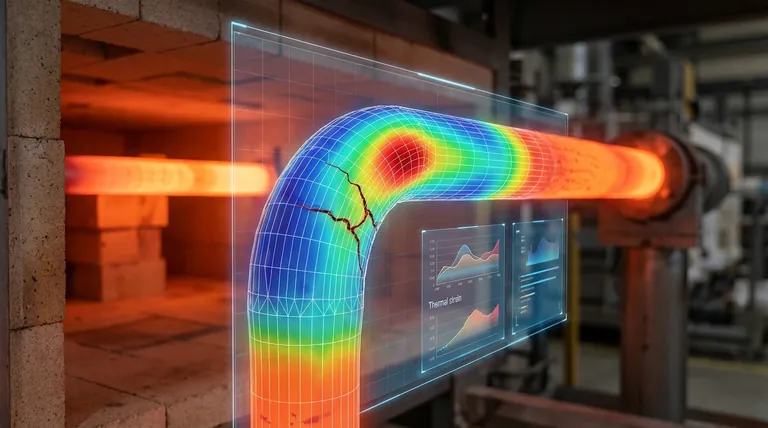

Thermal strain simulation analysis is the definitive tool for visualizing invisible stress factors within industrial radiant tubes before they are manufactured or deployed. It provides critical data on maximum stress concentrations, allowing engineers to verify that specific designs can withstand high-temperature deformation and resist fatigue cracking over time.

By revealing temperature gradients and strain values hidden within the metal structure, simulation transforms reliability from a guess into a calculated certainty. It empirically proves which tube geometries will survive the harshest thermal cycles.

Pinpointing Failure Mechanisms

Locating Maximum Stress Concentrations

In high-temperature environments, stress is rarely distributed even. Simulation acts as a diagnostic tool to identify exactly where stress accumulates the most.

Knowing the precise location of these "hotspots" is essential for predicting where a tube is likely to fail. This allows engineers to reinforce specific areas or alter the geometry to redistribute the load.

Predicting High-Temperature Deformation

Radiant tubes are subject to extreme thermal forces that cause physical warping over time. Simulation models these forces to predict how the material will deform under operating conditions.

By anticipating deformation patterns, you can prevent structural interference within the furnace. This ensures that the tube maintains its shape and function throughout its service life.

Preventing Fatigue Cracking

Cyclic heating and cooling create fatigue, the primary enemy of industrial hardware. Simulation analysis links stress data directly to the likelihood of fatigue cracking.

This predictive capability is vital for long-term reliability. It ensures that the chosen material and design can absorb thermal cycles without developing catastrophic fractures.

The Role of Geometry in Reliability

Comparing Structural Designs

Simulation provides an objective platform to compare different tube geometries, such as U-type versus double-P radiant tubes.

It moves the evaluation beyond theoretical drawings. You can observe how different shapes handle the same thermal load, highlighting the inherent advantages of one structure over another.

Reducing Temperature Gradients

A major cause of failure is uneven heating, known as a temperature gradient. Optimized designs, identified through simulation, demonstrate the ability to achieve smaller, more manageable gradients.

When the temperature difference across the tube is minimized, the internal stress on the material drops significantly.

Validating Lower Strain Values

The ultimate metric for reliability in this context is strain. Simulation confirms that optimized designs result in objectively lower strain values.

This numerical evidence confirms the superiority of specific designs. It proves that the geometry is not just efficient, but physically robust against the environment it operates in.

Common Pitfalls in Design Evaluation

Overlooking the "Delta"

A common mistake is focusing solely on the maximum operating temperature rather than the temperature gradient.

Materials often fail not because they are too hot, but because one part is significantly hotter than an adjacent part. Simulation forces you to acknowledge and address these dangerous differentials.

Ignoring Geometry-Specific Weaknesses

Without simulation, it is easy to assume that a "stronger" material will solve reliability issues.

However, even the best materials will fail if the design geometry concentrates stress in a corner or bend. Relying on material properties without analyzing the structural geometry is a significant risk to longevity.

Making the Right Choice for Your Equipment

To ensure the material reliability of your industrial radiant tubes, use simulation results to guide your procurement or design decisions.

- If your primary focus is preventing premature failure: Prioritize designs that show minimized stress concentrations in the simulation data, specifically looking for low peak stress values.

- If your primary focus is long-term structural integrity: Select geometries, such as the double-P design, that have been proven to generate smaller temperature gradients compared to standard U-types.

- If your primary focus is validating a new design: Require simulation evidence that demonstrates lower strain values under operating conditions before approving fabrication.

Simulation is the bridge between a theoretical drawing and a durable, reliable industrial asset.

Summary Table:

| Key Metric | Importance in Simulation | Benefit to Reliability |

|---|---|---|

| Stress Concentration | Identifies "hotspots" in geometry | Allows reinforcement to prevent structural failure |

| Temperature Gradient | Measures heat distribution across metal | Reduces internal stress by ensuring uniform heating |

| Deformation Modeling | Predicts physical warping over time | Prevents interference and ensures furnace structural integrity |

| Strain Values | Calculates material displacement | Empirically validates the durability of tube designs |

Elevate Your Industrial Reliability with KINTEK

Don't leave the longevity of your high-temperature equipment to chance. KINTEK leverages advanced engineering insights to deliver high-performance radiant tubes and heating systems designed to survive the harshest thermal cycles.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your unique structural and thermal requirements. Whether you need to minimize temperature gradients or prevent fatigue cracking, our team is ready to provide the precision-engineered solutions your laboratory or industrial facility demands.

Ready to optimize your thermal processes? Contact our experts today to secure durable, simulation-verified equipment.

Visual Guide

References

- Chien-Cheng Lin, Chien-Hsiung Tsai. Simulation of Staged Combustion Function in Double P-Type Radiant Tubes. DOI: 10.3390/engproc2025092094

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How is temperature controlled in resistance heating? Master Precise Heat Management for Your Lab

- How do MoSi2 heating elements perform in terms of heating and cooling cycles? Discover Rapid Thermal Cycling Benefits

- Why are multiple sets of resistance heaters used in varying positions for calorimeter calibration? Ensure Spatial Accuracy

- What should be considered when selecting graphite heating elements for a specific application? Optimize Your High-Temperature Process

- What makes silicon carbide heating elements suitable for laboratory furnaces? Achieve Precise, Uniform Heat for Reliable Experiments

- Why is a high-purity quartz tube utilized as a reaction chamber for plastic pyrolysis? Top Benefits and Performance

- What are silicon carbide (SiC) heating elements made of? A Guide to Extreme-Temperature Performance

- What precautions should be taken during the installation of heating elements? Ensure Longevity and Performance