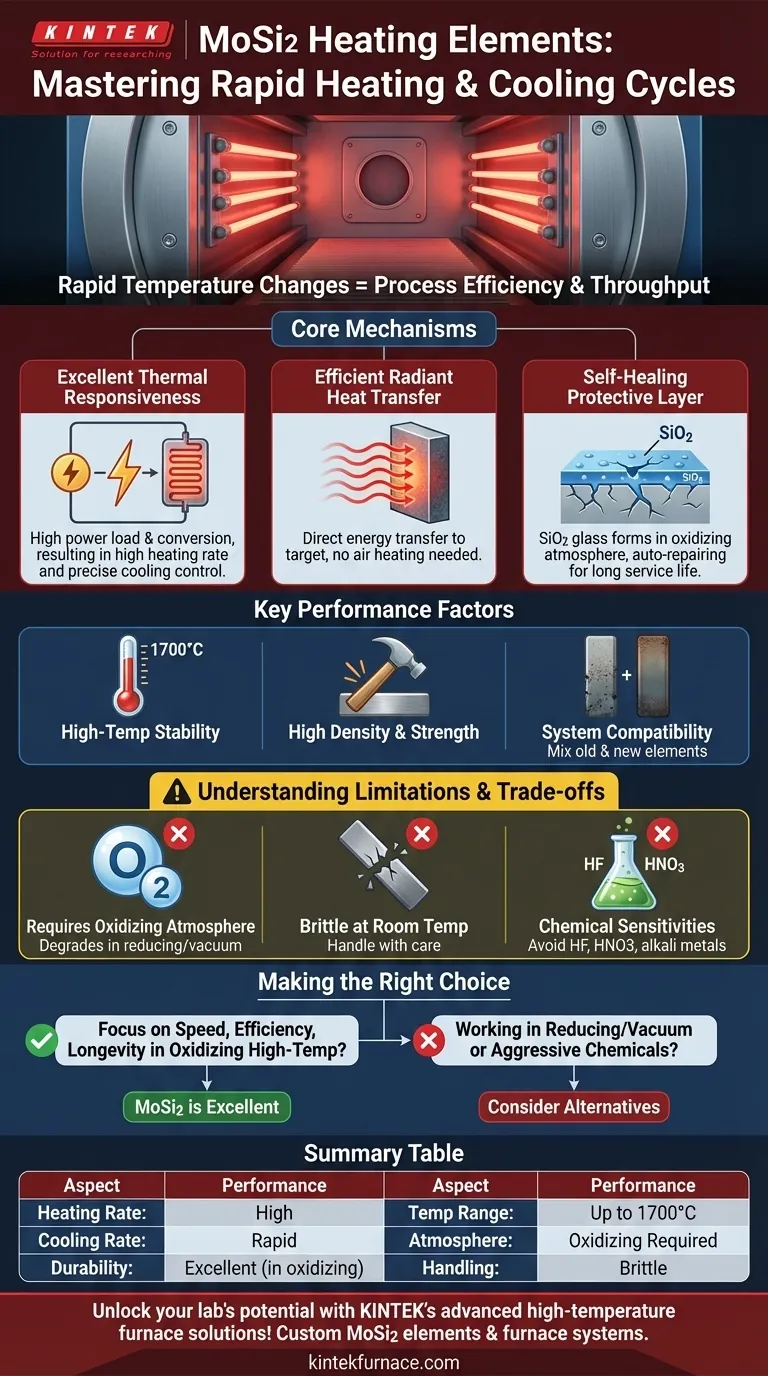

In short, Molybdenum Disilicide (MoSi2) heating elements perform exceptionally well in applications requiring rapid heating and cooling cycles. Their excellent thermal responsiveness allows for quick temperature changes, which directly improves process efficiency and throughput. This capability is a defining characteristic of MoSi2 technology.

The key to MoSi2's performance in thermal cycling is not just its speed, but its resilience. A unique, self-healing protective layer of silica glass forms on the element's surface in oxidizing atmospheres, repairing micro-cracks and ensuring a long service life despite the stresses of repeated temperature changes.

The Core Mechanisms Behind Rapid Cycling

Understanding why MoSi2 elements excel requires looking at a combination of their thermal, radiative, and chemical properties.

Excellent Thermal Responsiveness

MoSi2 elements have high electrical conductivity and can handle high power loads. This allows a large amount of energy to be converted into heat very quickly, resulting in a high heating rate and low overall power consumption for a given process.

This inherent efficiency also works in reverse, allowing the elements to cool down rapidly once power is removed, enabling precise temperature profile control.

Efficient Radiant Heat Transfer

These elements primarily emit heat through thermal radiation. Unlike convection or conduction, radiant heat travels directly to the target material without needing to heat the surrounding air first.

This direct energy transfer is extremely fast and efficient, further contributing to the rapid heating of the product or workspace.

The Self-Healing Protective Layer

This is the most critical feature for longevity in cyclical operations. When heated in an atmosphere containing oxygen, a thin, non-porous layer of silica glass (SiO2) forms on the element's surface.

If micro-cracks develop due to the thermal stress of heating and cooling, the underlying MoSi2 material is exposed to oxygen, instantly regenerating the protective silica layer. This "auto-repair" function is vital for durability.

Key Performance Factors and Characteristics

Several other properties contribute to the suitability of MoSi2 for demanding, high-temperature cycling.

High-Temperature Stability

MoSi2 elements are designed for extreme heat. Standard models like the BR1700 and BR1800 are rated for continuous operating temperatures up to 1600°C (2912°F) and 1700°C (3092°F), respectively. They remain stable and functional through repeated cycles up to these limits.

High Material Density and Strength

Modern MoSi2 elements are manufactured with high density and possess strong impact resistance, particularly at operating temperatures. This physical robustness helps them withstand the mechanical stresses induced by thermal expansion and contraction during rapid cycling.

Compatibility and System Design

A significant advantage is that old and new elements can typically be used together in the same system without issue. This simplifies maintenance and reduces downtime, as you can replace a single failed element rather than an entire set.

Understanding the Trade-offs and Limitations

While powerful, MoSi2 elements are not universally applicable. Understanding their operational constraints is crucial for success.

Requirement for an Oxidizing Atmosphere

The self-healing silica layer can only form in the presence of oxygen. Using these elements in a reducing or vacuum atmosphere at high temperatures will prevent this layer from forming, leading to rapid degradation and element failure.

Brittleness at Room Temperature

Like many ceramic-based materials, MoSi2 elements are brittle at low (room) temperatures. They must be handled with care during shipping, installation, and furnace maintenance to avoid fracture.

Chemical Sensitivities

The protective silica layer is highly resistant to most forms of corrosion. However, it is vulnerable to certain chemicals. MoSi2 elements will be attacked and quickly destroyed by hydrofluoric acid and nitric acid, and their performance can be compromised by the presence of certain alkali metals.

Making the Right Choice for Your Application

Use these guidelines to determine if MoSi2 is the correct technology for your specific needs.

- If your primary focus is process speed and efficiency: MoSi2 is an excellent choice, as its rapid thermal response can significantly shorten cycle times.

- If your primary focus is longevity in a cyclical, high-temp furnace: MoSi2 is highly suitable, provided you operate within an oxidizing atmosphere to enable its crucial self-healing properties.

- If you are working in a reducing atmosphere or vacuum: You must consider alternative heating elements, as MoSi2 will degrade without oxygen to form its protective layer.

- If your process involves aggressive chemical vapors: You must verify chemical compatibility, as MoSi2 elements are vulnerable to specific acids and other compounds.

By matching the unique properties of MoSi2 elements to your specific operating environment, you can leverage their exceptional performance for a highly efficient and reliable process.

Summary Table:

| Aspect | Performance |

|---|---|

| Heating Rate | High, due to excellent thermal responsiveness and efficient radiant heat transfer |

| Cooling Rate | Rapid, enabling precise temperature control and reduced cycle times |

| Durability | Excellent, with self-healing silica layer in oxidizing atmospheres for long service life |

| Temperature Range | Up to 1700°C (3092°F) for standard models, stable in repeated cycles |

| Atmosphere Compatibility | Requires oxidizing conditions; not suitable for reducing or vacuum environments |

| Handling | Brittle at room temperature; requires careful installation and maintenance |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable MoSi2 heating elements and custom furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, boosting efficiency and throughput. Don't let thermal cycling challenges slow you down—contact us today to discuss how our solutions can enhance your processes and deliver superior results!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element