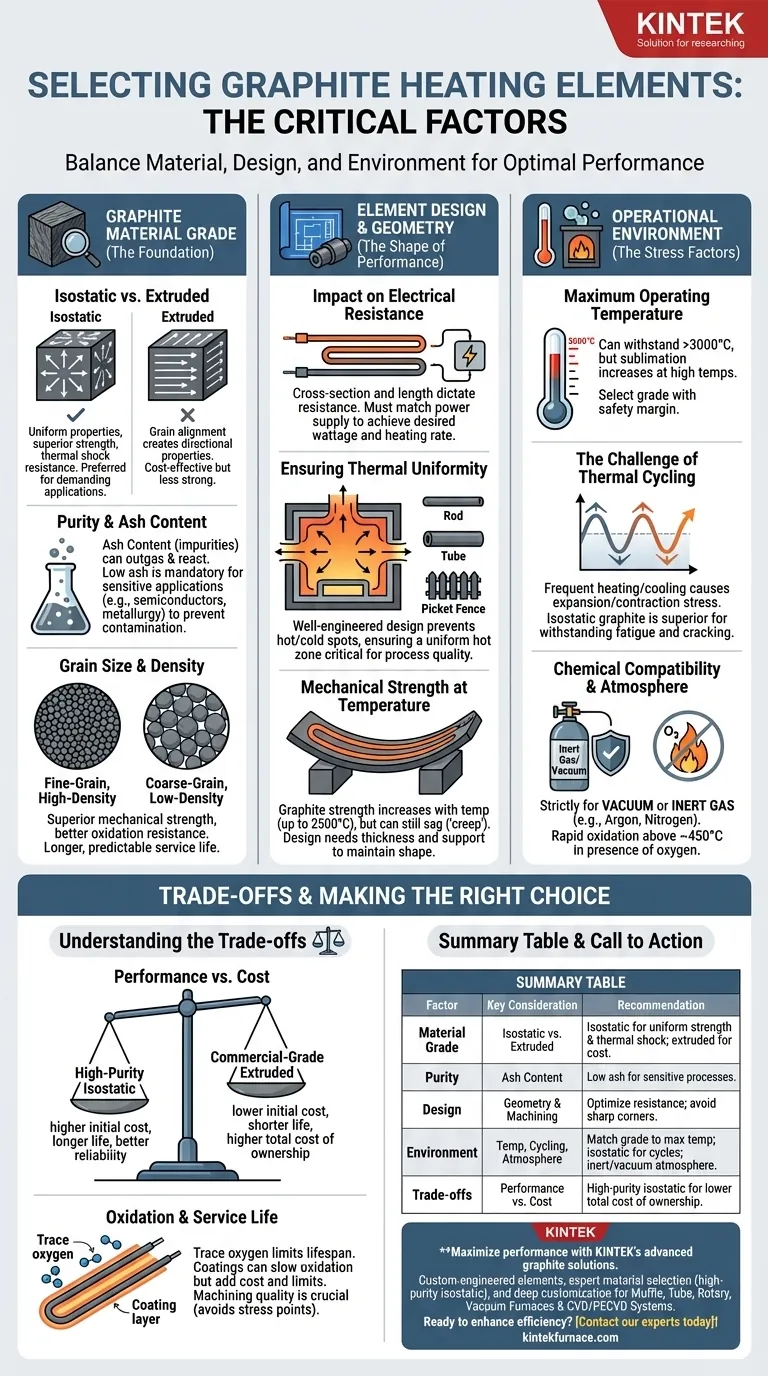

To select the right graphite heating element, you must evaluate three core operational factors: the maximum operating temperature, the frequency and intensity of thermal cycles, and the chemical environment inside your furnace. The choice is a direct function of balancing the graphite's material grade and physical design against the specific demands of your high-temperature process.

The optimal graphite heating element is not simply the one with the highest temperature rating. It is the one whose material grade, purity, and geometric design are precisely matched to the thermal, mechanical, and chemical stresses of your application, ensuring reliability and a predictable service life.

The Foundation: Graphite Material Grade

Before considering the element's shape or size, you must start with the raw material. The type of graphite block used for machining is the single most important factor determining the element's performance and longevity.

Isostatic vs. Extruded Graphite

Isostatically pressed graphite is formed by applying equal pressure from all directions. This creates a highly uniform (isotropic) material with consistent properties, superior strength, and excellent resistance to thermal shock. It is the preferred choice for demanding applications.

Extruded graphite is formed by pushing the material through a die. This process aligns the graphite grains, resulting in properties that vary with direction (anisotropic). While more cost-effective, it is generally less strong and less suitable for complex shapes or high-stress environments.

Purity and Ash Content

The purity of the graphite is critical for preventing contamination of the materials being processed (the "workload"). Ash content, which represents non-graphitic impurities, can outgas at high temperatures and react with your product. For sensitive applications like semiconductor manufacturing or metallurgy, a very low ash content is mandatory.

Grain Size and Density

A fine-grain, high-density graphite material generally provides superior mechanical strength and better resistance to oxidation. This makes it more robust and less prone to erosion, leading to a longer and more predictable service life, especially in furnaces that are not perfectly sealed.

Element Design and Geometry

The way a heating element is shaped from the raw graphite block has profound implications for its electrical performance and mechanical stability. The manufacturer's machining capability is just as important as the material itself.

Impact on Electrical Resistance

The element's cross-sectional area and length dictate its total electrical resistance. This is a critical design parameter that must be matched to your power supply's voltage and current capabilities to achieve the desired power output (wattage) and heating rate.

Ensuring Thermal Uniformity

The element's design is key to creating a uniform "hot zone" within the furnace. Common shapes include simple rods and tubes or more complex serpentine or "picket fence" designs. A well-engineered design distributes heat evenly, preventing hot or cold spots that can compromise your process.

Mechanical Strength at Temperature

Graphite is unique in that its strength increases with temperature, peaking around 2500°C. However, it can still sag or warp under its own weight over time ("creep"). The element's design must include sufficient thickness and appropriate support structures to maintain its shape and integrity at peak operating temperature.

The Operational Environment

Your furnace's specific operating conditions will exert constant stress on the heating elements. Matching the element to these conditions is essential for reliability.

Maximum Operating Temperature

While graphite can withstand temperatures over 3000°C in a vacuum or inert atmosphere, its rate of sublimation (turning from a solid directly to a gas) increases dramatically at very high temperatures. Select a grade rated for your target temperature with a comfortable safety margin.

The Challenge of Thermal Cycling

Every time the furnace is heated and cooled, the heating element expands and contracts, inducing mechanical stress. Frequent or rapid thermal cycles can lead to fatigue and cracking. Isostatic graphite is far superior in its ability to withstand this stress compared to extruded grades.

Chemical Compatibility and Atmosphere

Graphite will rapidly oxidize and burn away in the presence of oxygen at temperatures above approximately 450°C (842°F). Therefore, graphite elements are strictly for use in vacuum or inert gas atmospheres (like argon or nitrogen). You must also consider potential reactions between the graphite and any process gases or materials being heated.

Understanding the Trade-offs

Choosing a heating element involves balancing competing priorities. An objective assessment of these trade-offs is key to making a sound investment.

Performance vs. Cost

High-purity, fine-grain isostatic graphite is significantly more expensive than commercial-grade extruded graphite. However, its longer service life, improved process purity, and greater reliability can result in a lower total cost of ownership in demanding applications.

Oxidation and Service Life

No vacuum or inert atmosphere is perfect. Trace amounts of oxygen and water vapor will always be present, and they are the primary factors limiting the element's lifespan. While protective coatings (like silicon carbide) can slow this process, they add cost and have their own thermal limitations.

The Importance of Machining Quality

Even the best graphite material can fail prematurely if it is machined improperly. Sharp corners, surface scratches, or tool marks create stress concentration points where cracks can form and propagate during thermal cycling. Partnering with an experienced and skilled graphite machinist is non-negotiable.

Making the Right Choice for Your Application

Use your primary process goal to guide your final selection.

- If your primary focus is maximum purity and performance (e.g., R&D, semiconductors): Prioritize a high-purity, fine-grain isostatic graphite and work with your supplier to create a design optimized for your specific furnace geometry.

- If your primary focus is cost-sensitive, high-volume production: Carefully evaluate if a high-quality extruded graphite can meet your needs, but track its service life meticulously to calculate the true cost-per-cycle.

- If your primary focus is withstanding aggressive thermal cycling: Select a high-density isostatic graphite and a design that minimizes sharp angles and provides robust mechanical support.

A systematic approach to selection transforms the heating element from a simple consumable part into a strategic component that enhances process stability and control.

Summary Table:

| Selection Factor | Key Consideration | Recommendation |

|---|---|---|

| Material Grade | Isostatic vs. Extruded Graphite | Isostatic for uniform strength & thermal shock resistance; extruded for cost-sensitive applications. |

| Purity | Ash Content | Low ash content for sensitive processes (e.g., semiconductors) to prevent contamination. |

| Design | Geometry & Machining Quality | Optimize cross-section for electrical resistance; avoid sharp corners to reduce stress points. |

| Operational Environment | Temperature, Cycling, Atmosphere | Match grade to max temperature; use isostatic graphite for frequent thermal cycles; ensure inert/vacuum atmosphere. |

| Trade-offs | Performance vs. Cost | High-purity isostatic graphite offers longer service life and reliability, reducing total cost of ownership. |

Maximize the performance and lifespan of your high-temperature furnace with KINTEK's advanced graphite heating solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precisely engineered heating elements tailored to your unique requirements. Our expertise in material selection (including high-purity, fine-grain isostatic graphite) and custom design ensures optimal thermal uniformity, mechanical stability, and chemical compatibility for your application. Whether you need Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, or CVD/PECVD Systems, our deep customization capabilities deliver reliability and process control. Ready to enhance your furnace's efficiency? Contact our experts today to discuss your needs!

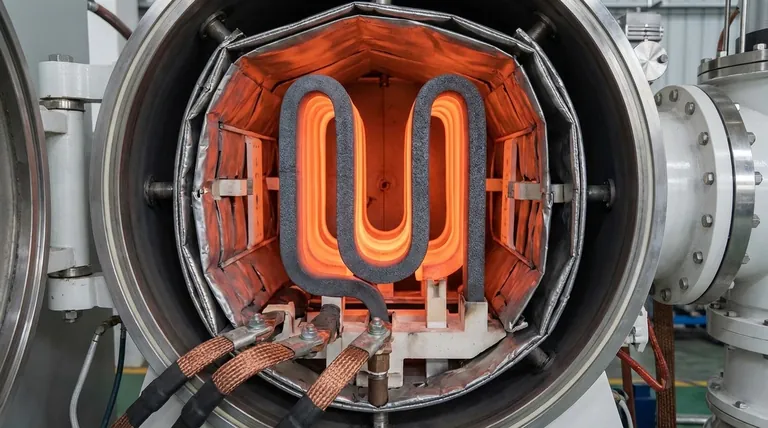

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity