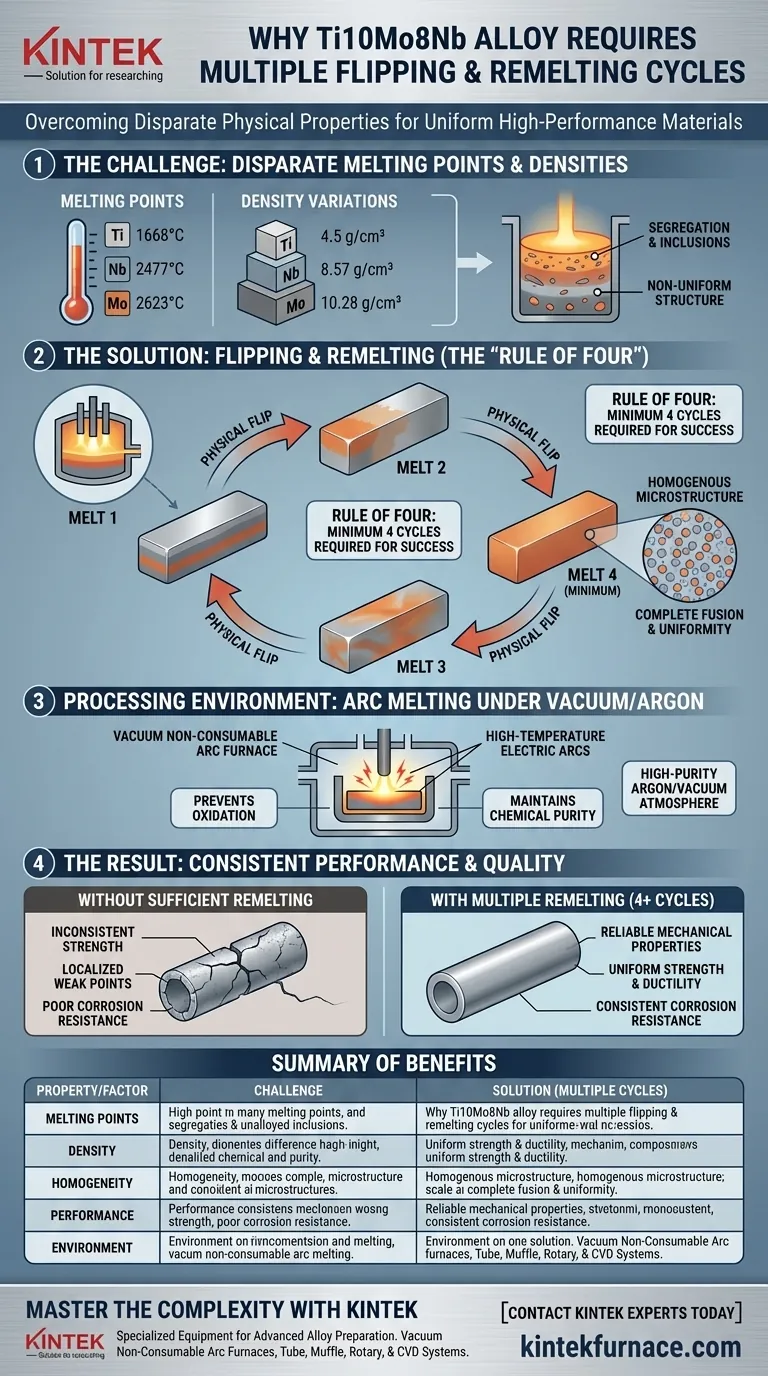

Multiple flipping and remelting cycles are strictly necessary to overcome substantial differences in density and melting points between Titanium, Molybdenum, and Niobium. Without this iterative process, the Ti10Mo8Nb alloy will fail to achieve the compositional homogeneity required for reliable performance.

The core challenge in creating Ti10Mo8Nb lies in fusing elements with vastly different physical properties. At least four remelting cycles are required to eliminate compositional segregation, ensuring the uniform internal structure necessary for consistent mechanical strength and corrosion resistance.

The Physical Challenge of Ti10Mo8Nb

Disparate Melting Points

The raw materials used—Titanium (Ti), Molybdenum (Mo), and Niobium (Nb)—are all high-melting-point metals, but they do not melt at the same temperature.

If melted only once, the element with the highest melting point may not fully fuse with the others. This leads to distinct, unalloyed inclusions within the material rather than a single, cohesive solid solution.

Density Variations

In addition to thermal differences, these three elements have significantly different densities.

During a single melt, heavier elements tend to sink to the bottom of the crucible, while lighter elements float. This creates a vertical gradient where the chemical composition at the top of the ingot differs radically from the bottom.

Achieving Compositional Uniformity

Eliminating Segregation

To counteract the physics of sinking and separation, the alloy must be subjected to multiple remelting cycles.

By physically flipping the ingot between melts, you invert the density gradient. Repeating this process forces the heavy and light elements to mix thoroughly, effectively eliminating compositional segregation.

The "Rule of Four"

Research indicates that a minimum of four remelting cycles is the threshold for success with Ti10Mo8Nb.

Fewer cycles often result in a heterogeneous mixture. Reaching this four-cycle baseline ensures that the distribution of elements is uniform at both the macroscopic and microscopic scales.

Ensuring Consistent Properties

Uniformity is not just aesthetic; it dictates performance.

A homogenous microstructure guarantees that mechanical properties (such as strength and ductility) and corrosion resistance are consistent throughout the entire component.

The Role of the Processing Environment

High-Temperature Arc Melting

To handle these refractory metals, a vacuum non-consumable arc furnace is utilized.

This equipment uses high-temperature electric arcs to achieve the extreme heat necessary to completely melt the Ti, Mo, and Nb raw materials.

Preventing Oxidation

The melting process must occur under a high-purity argon atmosphere or vacuum.

Because these metals are reactive at high temperatures, this inert environment is critical. It prevents the alloy from oxidizing, thereby maintaining the chemical purity and accurate composition required for sensitive applications, such as biomedical components.

Understanding the Trade-offs

Process Efficiency vs. Material Quality

The primary trade-off in this process is time and energy consumption.

Requiring at least four flip-and-remelt cycles significantly extends the manufacturing timeline compared to simpler alloys. However, this "inefficiency" is the unavoidable cost of working with complex, high-performance alloys like Ti10Mo8Nb.

The Risk of Shortcutting

Attempting to reduce the number of cycles to save time is a common pitfall.

Stopping after two or three cycles may produce an ingot that looks solid, but internally, it will likely suffer from localized weak points and inconsistent corrosion behavior due to retained segregation.

Making the Right Choice for Your Goal

When preparing Ti10Mo8Nb, the process parameters must align with the final application requirements.

- If your primary focus is mechanical reliability: Adhere strictly to the minimum of four remelting cycles to guarantee the elimination of microscopic segregation.

- If your primary focus is chemical purity: Ensure your arc furnace utilizes a high-vacuum or high-purity argon environment to prevent oxidation during the extended melting times.

Ultimately, the uniformity of the alloy—and its resulting performance—is directly proportional to the rigor of the remelting process.

Summary Table:

| Property/Factor | Challenge in Ti10Mo8Nb Production | Solution: Multiple Flipping & Remelting |

|---|---|---|

| Melting Points | High & varied (Ti, Mo, Nb) | Ensures complete fusion of all refractory elements |

| Density | High variation; causes elements to sink/float | Physical flipping inverts gradients for thorough mixing |

| Homogeneity | Risk of compositional segregation | Minimum of 4 cycles ensures microscopic uniformity |

| Performance | Inconsistent strength & corrosion resistance | Guarantees reliable mechanical properties throughout |

| Environment | Oxidation risk at high temperatures | Vacuum/Argon arc melting maintains chemical purity |

Master the Complexity of Advanced Alloy Preparation

Producing high-performance materials like Ti10Mo8Nb requires precision, persistence, and the right technology. At KINTEK, we understand that shortcuts in the melting process lead to material failure. Backed by expert R&D and world-class manufacturing, we provide the specialized equipment you need to achieve perfection.

Whether you require Vacuum Non-Consumable Arc Furnaces, Tube, Muffle, Rotary, or CVD systems, our laboratory high-temperature furnaces are fully customizable to meet your unique metallurgical needs. Ensure absolute compositional homogeneity and mechanical reliability in every ingot.

Ready to elevate your material research? Contact KINTEK experts today for custom furnace solutions!

Visual Guide

References

- Edwin Gilberto Medina Bejarano, Daniela Sachs. Evaluation of corrosion resistance and biocompatibility test of Ti10Mo8Nb alloy for biomedical applications. DOI: 10.33448/rsd-v14i5.48744

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- How does induction heating contribute to a cleaner work environment? Boost Quality & Sustainability

- What is the frequency range used in induction heating systems? Optimize Your Heating Depth & Efficiency

- What are the advantages of induction heating over other melting methods? Unlock Speed, Purity & Control

- What is the role of the quartz nozzle in half-Heusler induction melting? Optimize Alloy Ribbon Precision

- What is the working principle of an induction melting furnace? Achieve Fast, Clean, and Controllable Metal Melting

- What are the main types of induction furnaces? Choose the Right Design for Your Melting Needs

- What role does a non-consumable vacuum arc furnace play in Ti–Cu alloy preparation? Achieving High-Purity Synthesis

- What role does vacuum induction melting equipment play in the preparation of CrFeNi alloys? Essential Purity Guide