At its core, an induction heating system's operating frequency is not a single value but a wide spectrum, typically ranging from line frequency (50/60 Hz) up to several hundred kilohertz (kHz). The specific frequency is chosen based on the material, the size of the part, and most importantly, the desired depth of heat penetration.

The fundamental principle to understand is this: frequency is the primary control for heating depth. Low frequencies penetrate deeply into a metal part, while high frequencies concentrate the heat near the surface. Selecting the correct frequency is therefore critical to achieving the desired outcome, whether it's melting a large crucible or hardening a thin gear tooth.

The Role of Frequency in Induction Heating

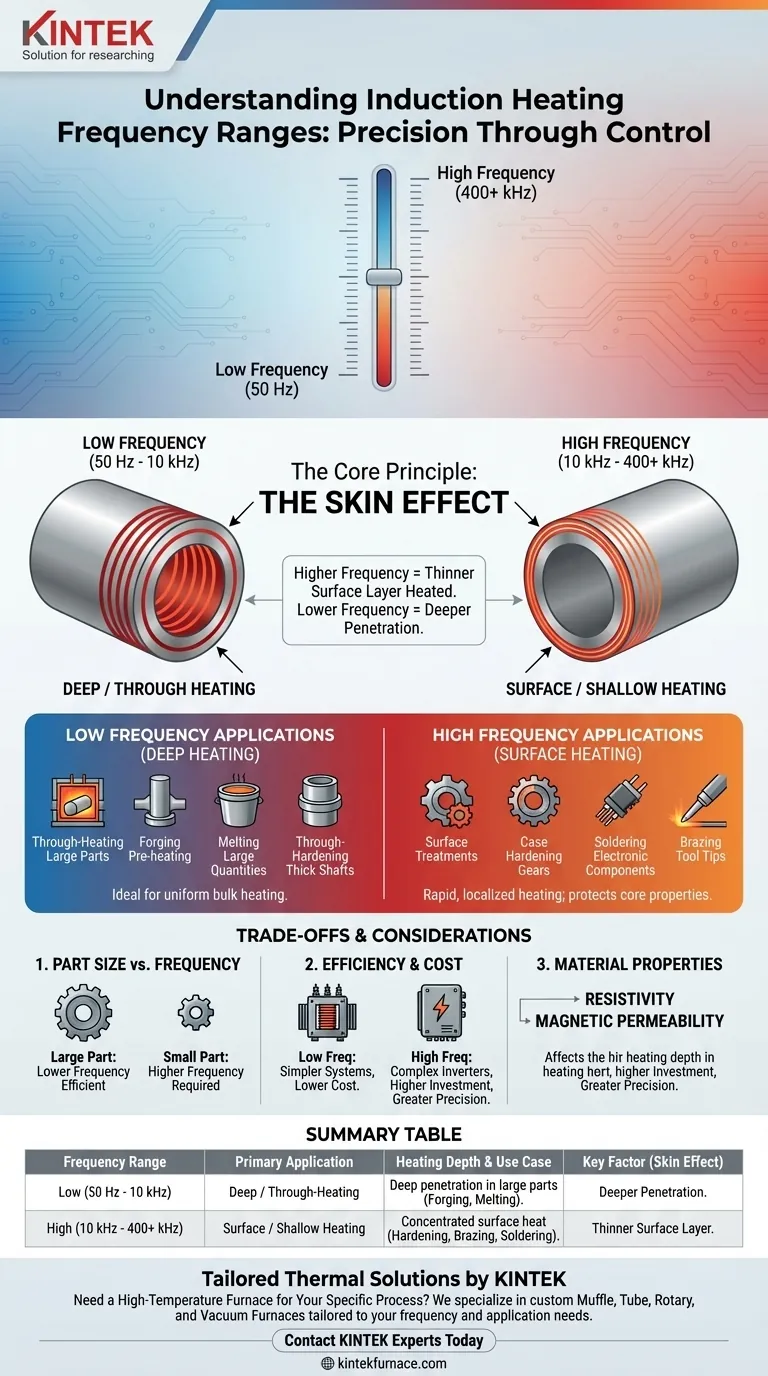

The choice of frequency is a deliberate engineering decision that directly dictates how the workpiece is heated. This relationship is governed by a physical principle known as the "skin effect."

Introducing the Skin Effect

The skin effect describes the tendency of an alternating electrical current (AC) to become distributed within a conductor so that the current density is largest near the surface.

As the frequency of the current increases, the current flows in a progressively thinner layer at the surface. Since induction heating works by inducing these currents, a higher frequency means the heat is also generated in this thinner surface layer.

Low-Frequency Applications (Deep Heating)

Frequencies from 50 Hz to around 10 kHz are considered low for induction processes. At these frequencies, the induced current penetrates deeply into the metal.

This makes low-frequency induction ideal for applications requiring through-heating or bulk heating of large parts. Common uses include pre-heating massive billets for forging, melting large quantities of metal in a crucible, or through-hardening thick shafts.

High-Frequency Applications (Surface Heating)

Frequencies from 10 kHz to 400 kHz and higher are used when heat must be generated in a very shallow surface layer, often less than a millimeter deep.

This precise, localized heating is perfect for surface treatments. Applications like case hardening gears, soldering electronic components, and brazing tool tips all rely on high frequencies to heat the surface rapidly without affecting the core properties of the material.

The Link Between Frequency and Efficiency

For surface heating applications, high frequencies are inherently more efficient. By concentrating a massive amount of energy into a very small volume (the thin "skin"), the surface temperature rises extremely quickly.

This rapid heating minimizes the time for heat to conduct into the core of the part, reducing wasted energy and preventing unwanted changes to the underlying material structure.

Understanding the Trade-offs

Choosing a frequency is not just about heating depth; it involves balancing technical requirements with practical constraints.

Frequency vs. Part Size

There is a direct relationship between the optimal frequency and the diameter of the part being heated. A large-diameter part can be heated efficiently with a lower frequency.

Conversely, trying to heat a very small part with a low frequency is highly inefficient, as the magnetic field may "miss" the part entirely. Small parts require higher frequencies for the energy to couple effectively.

Equipment Cost and Complexity

Generally, the equipment required to generate the frequency influences cost. Low-frequency systems can sometimes be simpler, leveraging transformers connected to the main power line.

High-frequency systems require sophisticated solid-state power inverters. While these offer precise control, they represent a greater investment in terms of complexity and initial cost.

Material Properties Matter

The exact heating depth is not determined by frequency alone. The material's electrical resistivity and magnetic permeability also play a crucial role in calculating the final skin depth. A full process design must account for all three variables.

Making the Right Choice for Your Goal

The optimal frequency is determined entirely by your process objective. Use the following guidelines to inform your decision.

- If your primary focus is through-heating large billets for forging or melting: A low frequency (typically below 5 kHz) is necessary to ensure the heat penetrates deeply and uniformly throughout the part's core.

- If your primary focus is surface hardening a steel component: A high frequency (30 kHz to 400 kHz) is required to create a shallow, hard case while leaving the core of the part tough and ductile.

- If your primary focus is brazing or soldering delicate parts: A very high frequency (100 kHz and above) provides rapid, localized heat that won't distort or damage adjacent areas, ensuring a clean and strong joint.

Ultimately, mastering induction heating means matching the frequency to the desired metallurgical outcome with precision.

Summary Table:

| Frequency Range | Primary Application | Heating Depth & Use Case |

|---|---|---|

| Low (50 Hz - 10 kHz) | Deep / Through-Heating | Penetrates deep into large parts; ideal for forging, melting, and bulk heating. |

| High (10 kHz - 400+ kHz) | Surface / Shallow Heating | Concentrates heat at the surface; perfect for hardening, brazing, and soldering. |

| Key Factor | Skin Effect | Higher frequency = thinner surface layer heated; lower frequency = deeper penetration. |

Need a High-Temperature Furnace Tailored to Your Specific Frequency and Process Requirements?

At KINTEK, we understand that the right thermal processing equipment is critical to achieving precise results in your induction heating, brazing, hardening, or melting applications. Our advanced furnace solutions are engineered to complement your process, ensuring optimal performance and reliability.

Why Choose KINTEK?

- Deep Customization: We don't just sell standard furnaces. Our strong R&D and in-house manufacturing capabilities allow us to tailor our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to your exact frequency, temperature, and atmosphere needs.

- Expert Support: Our team helps you select or design the perfect furnace for your material size, desired heating depth, and efficiency goals.

- Proven Performance: From laboratory research to industrial production, KINTEK furnaces deliver the precision and durability required for demanding thermal processes.

Let's engineer the perfect solution for your lab or facility. Contact our thermal experts today to discuss your project and receive a customized recommendation.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What are the applications of hot pressing? Achieve Maximum Material Performance