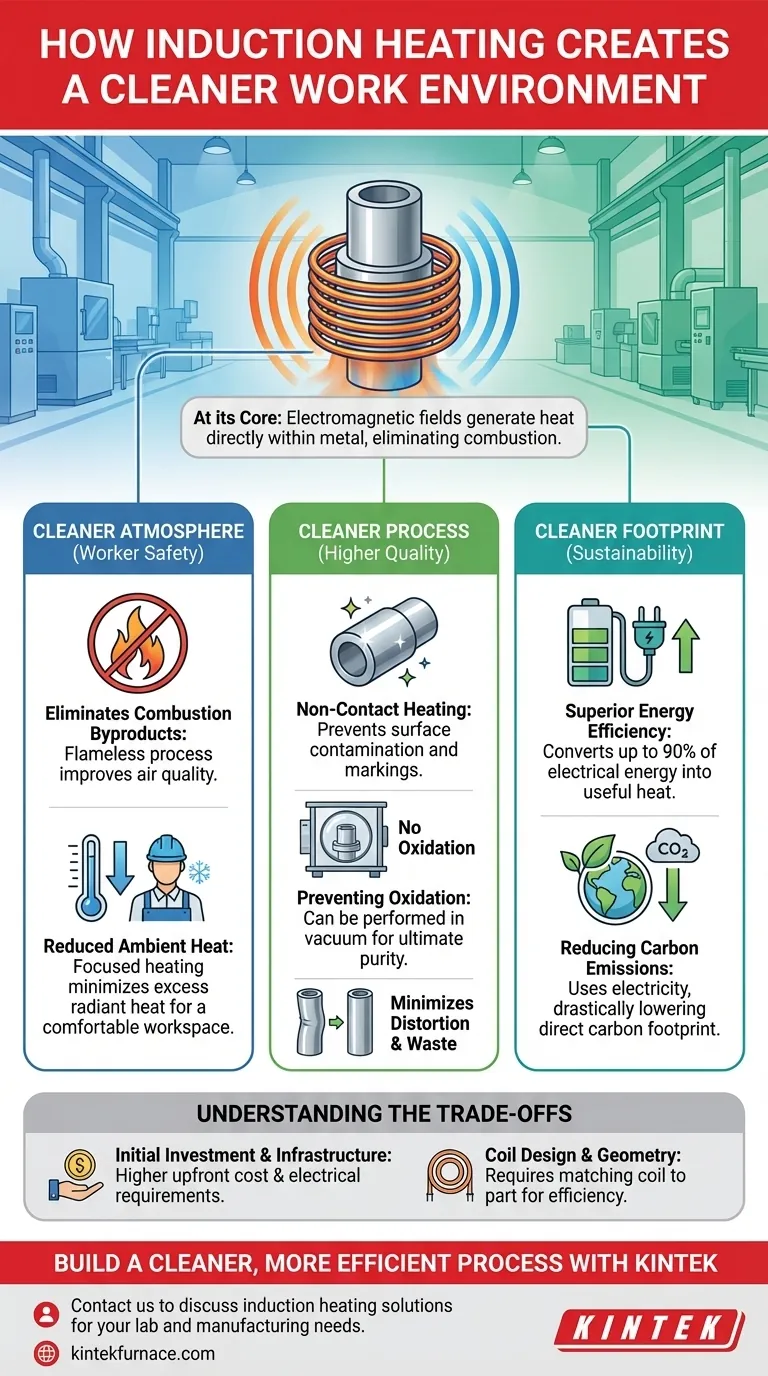

At its core, induction heating creates a cleaner work environment by eliminating the combustion inherent in traditional flame or furnace-based methods. Because it uses an electromagnetic field to generate heat directly within a metal part, it produces no smoke, exhaust, or harmful byproducts, leading to vastly improved air quality for workers.

A "cleaner" environment from induction heating is not just about cleaner air. It encompasses a cleaner manufacturing process with less material contamination and a cleaner energy profile with significantly lower carbon emissions.

A Cleaner Atmosphere for Your Team

The most immediate and noticeable benefit of induction heating is its positive impact on the air your employees breathe. This stems directly from the nature of the technology.

Eliminating Combustion Byproducts

Unlike furnaces or torches that burn fossil fuels, induction heating is a flameless process.

This complete absence of combustion means it does not release smoke, soot, or hazardous gases into the workspace. The result is a dramatic reduction in airborne contaminants, directly improving workplace air quality and enhancing employee well-being.

Reducing Ambient Heat

Traditional furnaces radiate immense heat, raising the temperature of the entire work area and creating uncomfortable, fatiguing conditions.

Induction heating is highly focused, generating heat only in the target part. This minimizes excess radiant heat, contributing to a safer and more comfortable environment.

A Cleaner Process for Higher Quality Parts

The "cleanliness" of induction extends to the manufacturing process itself, preventing contamination and improving the quality of the final product.

The Principle of Non-Contact Heating

Induction heating works by passing an alternating current through a copper coil, which creates a powerful electromagnetic field. This field induces electrical currents (eddy currents) within the metal part, generating precise and rapid heat from the inside out.

Crucially, the heating coil never touches the part. This non-contact approach prevents the surface contamination and markings that can occur with other methods.

Preventing Oxidation and Contamination

Because there is no flame, surface oxidation and scale are drastically reduced. For applications requiring ultimate purity, induction can be performed in a vacuum.

This isolates the material from atmospheric gases, completely preventing oxidation and ensuring the highest quality, uncontaminated end product.

Minimizing Distortion and Waste

The precise control of induction allows heat to be applied only where it is needed. This localized heating minimizes the risk of material warpage and distortion that often plagues through-heating methods.

The result is a higher consistency between parts, a significantly lower rejection rate, and less wasted material.

Understanding the Trade-offs

While the benefits are significant, adopting induction heating requires a clear-eyed assessment of its operational requirements. It is a technological shift, not a simple replacement.

Initial Investment and Infrastructure

Induction heating systems can represent a higher upfront capital investment compared to simple torches or conventional furnaces. They also require a robust electrical supply, which may necessitate infrastructure upgrades.

Coil Design and Part Geometry

The inductor coil must be designed to match the geometry of the part being heated for maximum efficiency. While versatile coils exist, highly complex or varied part shapes may require custom coil engineering, adding a layer of complexity.

A Cleaner Footprint for Your Organization

Beyond the factory floor, induction heating contributes to broader corporate goals related to environmental sustainability and operational efficiency.

Superior Energy Efficiency

Induction heating is exceptionally efficient, converting up to 90% of its electrical energy into useful heat within the part.

In contrast, fuel-fired furnaces lose a tremendous amount of energy heating the furnace walls and surrounding atmosphere, making induction a far less wasteful process.

Reducing Carbon Emissions

By using electricity instead of directly burning fossil fuels, induction heating dramatically lowers an organization's direct carbon footprint.

When paired with a grid increasingly powered by renewable sources, it provides a clear path toward meeting carbon neutrality targets and corporate sustainability goals.

Making the Right Choice for Your Goal

Adopting induction is a strategic decision that aligns with several key manufacturing priorities.

- If your primary focus is worker health and safety: Induction is the definitive choice for eliminating airborne contaminants and reducing ambient heat stress.

- If your primary focus is product quality and consistency: The precise, non-contact nature of induction minimizes distortion and prevents contamination, leading to fewer defects.

- If your primary focus is energy efficiency and sustainability: Induction's high electrical efficiency and lack of fossil fuel consumption significantly reduce energy costs and your carbon footprint.

Ultimately, choosing induction heating is an investment in a modern, efficient, and responsible manufacturing environment.

Summary Table:

| Benefit | How Induction Heating Achieves It |

|---|---|

| Cleaner Air | Eliminates smoke, soot, and harmful gases by using a flameless process. |

| Reduced Contamination | Non-contact heating prevents surface marking and oxidation. |

| Less Waste | Precise, localized heating minimizes part distortion and material waste. |

| Lower Emissions | Uses electricity, drastically reducing direct carbon footprint. |

| Energy Efficiency | Converts up to 90% of electrical energy into useful heat. |

Ready to Build a Cleaner, More Efficient Manufacturing Process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Contact us today to discuss how our induction heating solutions can help you achieve superior product quality, enhance workplace safety, and meet your sustainability goals.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the main applications of vacuum hot pressing? Create Dense, Pure Materials for Demanding Industries

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials