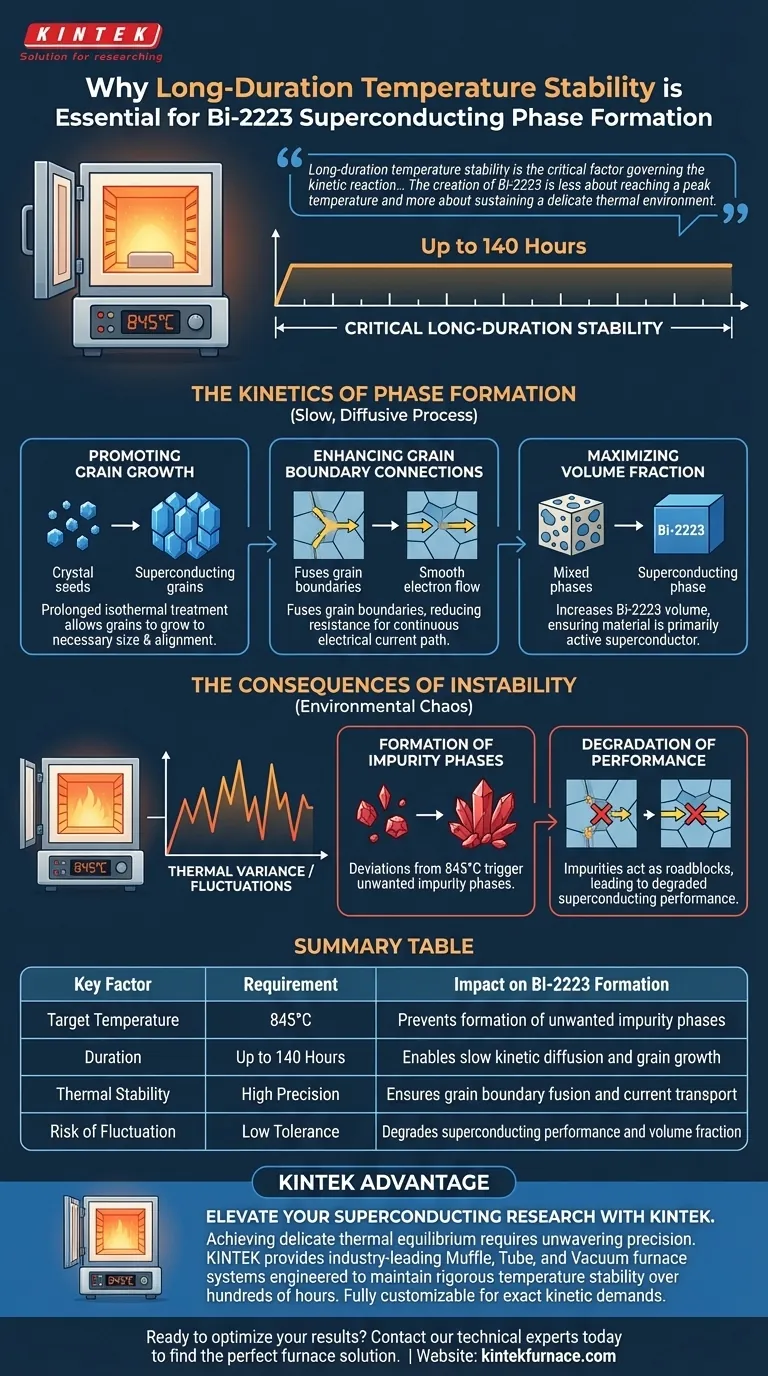

Long-duration temperature stability is the critical factor governing the kinetic reaction required to synthesize the Bi-2223 superconducting phase. To successfully form this material, a sintering furnace must maintain a precise temperature of 845°C for extended periods, often up to 140 hours, to ensure the proper growth of superconducting grains and the suppression of impurities.

The creation of Bi-2223 is less about reaching a peak temperature and more about sustaining a delicate thermal environment. Without rigorous stability over time, the slow kinetic processes required to structure the material will fail, leading to degraded superconducting performance.

The Kinetics of Phase Formation

Creating high-quality superconducting ceramics is a slow, diffusive process rather than an instantaneous reaction. The furnace acts as an incubator that must provide specific kinetic conditions to drive the material's internal restructuring.

Promoting Grain Growth

The Bi-2223 phase requires significant time to nucleate and expand. A prolonged isothermal treatment allows the superconducting grains to grow to the necessary size and alignment.

Enhancing Grain Boundary Connections

For a material to be superconducting, electrons must be able to move freely between grains. Long-duration sintering fuses these grain boundaries, reducing resistance and ensuring a continuous path for electrical current.

Maximizing Volume Fraction

The efficiency of the final material depends on how much of it is actually converted into the superconducting phase. Extending the treatment time increases the volume fraction of Bi-2223, ensuring the ceramic is composed primarily of the active superconducting material.

The Consequences of Instability

The primary challenge in sintering Bi-2223 is that the chemical reaction is highly sensitive to thermal variance. The furnace serves as a safeguard against environmental chaos.

Formation of Impurity Phases

If the temperature deviates from the target of 845°C, the chemical reaction path changes. These fluctuations trigger the formation of unwanted impurity phases rather than the desired superconductor.

Degradation of Performance

Impurity phases act as roadblocks to electron flow. Even minor thermal instability results in a material with degraded superconducting performance, rendering the long processing time wasted.

Making the Right Choice for Your Goal

When selecting furnace parameters or equipment for Bi-2223 synthesis, prioritize control systems capable of maintaining tight tolerances over extended timelines.

- If your primary focus is Phase Purity: Ensure the furnace can hold exactly 845°C without oscillation to prevent the nucleation of impurity phases.

- If your primary focus is Current Transport: Prioritize the duration of the cycle (up to 140 hours) to maximize grain boundary connectivity.

Precision in the thermal environment is the defining difference between a high-performance superconductor and a flawed ceramic.

Summary Table:

| Key Factor | Requirement | Impact on Bi-2223 Formation |

|---|---|---|

| Target Temperature | 845°C | Prevents formation of unwanted impurity phases |

| Duration | Up to 140 Hours | Enables slow kinetic diffusion and grain growth |

| Thermal Stability | High Precision | Ensures grain boundary fusion and current transport |

| Risk of Fluctuation | Low Tolerance | Degrades superconducting performance and volume fraction |

Elevate Your Superconducting Research with KINTEK

Achieving the delicate thermal equilibrium required for Bi-2223 demands more than just heat—it requires unwavering precision. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnace systems engineered to maintain rigorous temperature stability over hundreds of hours.

Backed by expert R&D and specialized manufacturing, our high-temp lab furnaces are fully customizable to meet the exact kinetic demands of your material synthesis. Ensure phase purity and maximize volume fraction with a partner who understands the science of sintering.

Ready to optimize your results? Contact our technical experts today to find the perfect furnace solution for your unique laboratory needs.

Visual Guide

References

- Bilal A. Omar, Abdulsalam S. Baqi. Effects of La2O3 Nanoparticles on the Superconducting Behavior of Bi1.60 Ag0.40 Sr1.9 Ba0.1 Ca2 Cu3 O10+δ Ceramics. DOI: 10.59324/stss.2025.2(6).08

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a laboratory vacuum drying oven necessary for SPC-Fe electrodes? Ensure Electrochemical Viability

- What is the difference between vacuum hardening and normal hardening? A Guide to Superior Surface Quality

- How does a crucible furnace operate? Master Indirect Heating for Pure Metal Melting

- How does vacuum carburizing ensure stable carburizing quality? Achieve Precise, Repeatable Heat Treatment

- How is furnace brazing used in research and development? Unlock Precision Joining for Material Innovation

- What are the key components of a condensation system in a vacuum distillation furnace? Achieve Superior Metal Vapor Separation

- In which industries are vacuum sintering furnaces commonly used? Essential for High-Performance Materials

- What role do laboratory high-temperature furnaces play in the growth of Ni3In2Se2 single crystals? Precision Growth Control