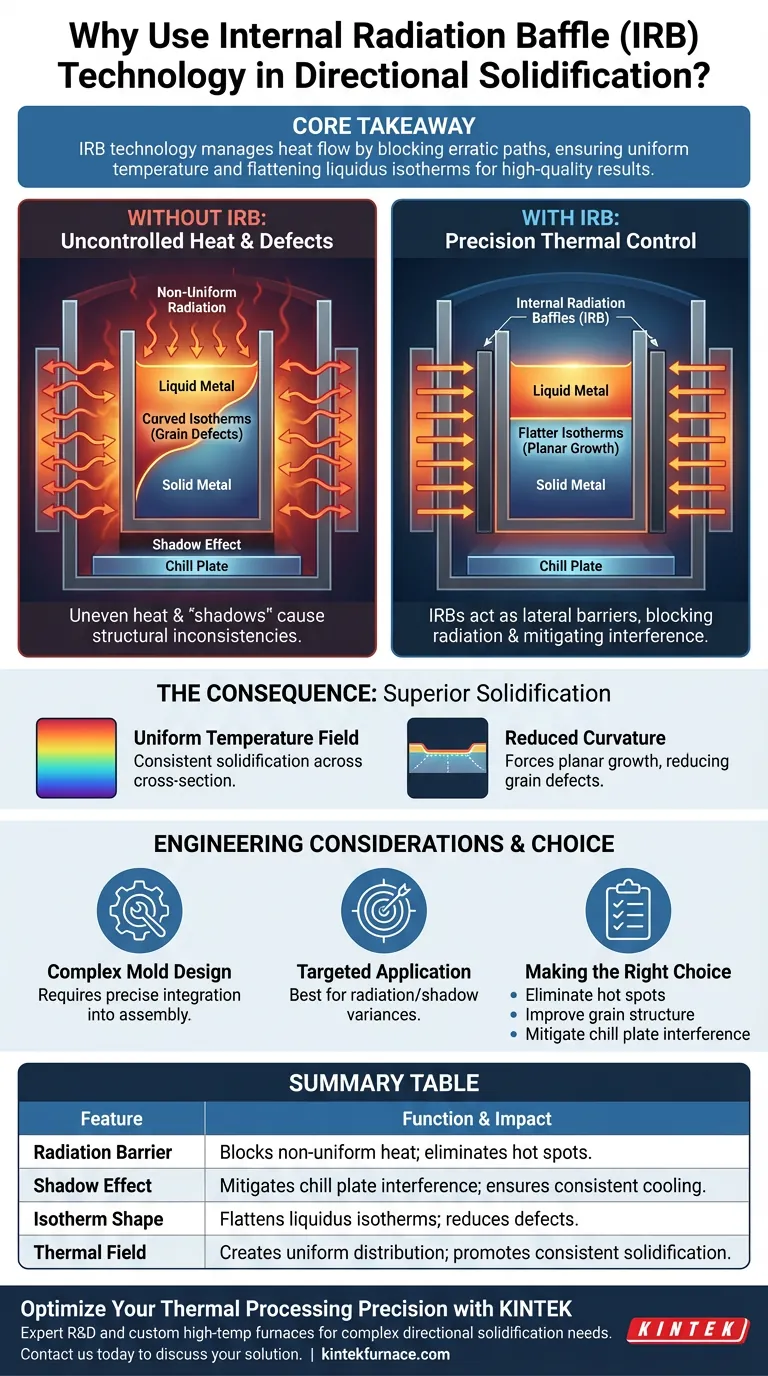

Internal Radiation Baffle (IRB) technology is essential for precisely managing heat flow dynamics within complex furnace environments. By integrating lateral thermal barriers directly into the mold assembly, this technology blocks non-uniform radiation from heaters and mitigates thermal interference caused by the chill plate. The result is a controlled thermal environment that is critical for high-quality directional solidification.

Core Takeaway In complex solidification processes, uneven heat distribution causes structural inconsistencies. IRB technology solves this by physically obstructing erratic heat paths, effectively flattening the liquidus isotherms to ensure a uniform temperature distribution throughout the mold.

The Mechanics of Thermal Control

Managing Non-Uniform Radiation

The primary function of an Internal Radiation Baffle is to act as a lateral thermal barrier.

Standard furnace heaters often emit radiation unevenly, creating hot spots or inconsistent thermal gradients. The IRB effectively blocks this non-uniform thermal radiation before it affects the solidifying material.

Mitigating the "Shadow Effect"

In directional solidification, the chill plate—used to draw heat out of the metal—can inadvertently create interference known as the shadow effect.

This phenomenon is particularly problematic in the upper sections of a mold. IRB technology modifies the mold design to reduce this interference, isolating the casting from the disruptive thermal "shadows" cast by the cooling hardware.

The Consequence: Flatter Isotherms

Reducing Curvature

The ultimate goal of using IRBs is to alter the shape of the liquidus isotherms (the boundary between liquid and solid metal).

In a standard setup, these isotherms often exhibit significant curvature, which can lead to grain defects. IRBs significantly reduce this curvature, forcing the solidification front to remain planar.

Uniform Temperature Fields

By blocking external radiation variance and managing the chill plate's influence, IRBs create a uniform temperature field distribution.

This uniformity ensures that the metal solidifies consistently across the entire cross-section of the mold, rather than cooling unevenly from the outside in.

Engineering Considerations

Complexity in Mold Design

While effective, implementing IRB technology requires modifying the standard mold assembly.

Engineers must account for the physical space these baffles occupy and ensure they are positioned correctly to intercept specific heat paths without obstructing necessary mold operations.

Targeted Application

IRBs are a specific solution for radiation and shadow-based thermal variances.

They are most effective when the root cause of the defect is external heat flow interference (from heaters or chill plates). They may not correct issues stemming solely from alloy composition or pour rates.

Making the Right Choice for Your Process

To determine if IRB technology is required for your specific application, consider your thermal objectives:

- If your primary focus is eliminating hot spots: Use IRBs to block non-uniform radiation emitted directly from the furnace heaters.

- If your primary focus is grain structure consistency: Implement IRBs to flatten the curvature of liquidus isotherms, particularly in the upper mold regions.

- If your primary focus is mitigating chill plate interference: Utilize this technology to reduce the shadow effect that distorts the thermal field.

By integrating Internal Radiation Baffles, you transform a variable thermal environment into a precise, uniform field conducive to superior directional solidification.

Summary Table:

| Feature | Function of IRB Technology | Impact on Solidification |

|---|---|---|

| Radiation Barrier | Blocks non-uniform heat from furnace heaters | Eliminates hot spots and thermal variance |

| Shadow Effect | Mitigates interference from the chill plate | Ensures consistent cooling in upper mold regions |

| Isotherm Shape | Flattens the curvature of liquidus isotherms | Reduces grain defects and ensures planar growth |

| Thermal Field | Creates a uniform temperature distribution | Promotes consistent solidification across the cross-section |

Optimize Your Thermal Processing Precision with KINTEK

Achieving perfect grain structure requires more than just high temperatures—it requires absolute thermal control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temp furnaces tailored for your most complex directional solidification needs. Whether you are managing complex mold designs or seeking to eliminate thermal interference, our engineering team is ready to provide the specialized equipment your research demands.

Ready to elevate your material consistency? Contact us today to discuss your custom furnace solution.

Visual Guide

References

- Effect of Temperature Profile Curvature on the Formation of Atypical Inhomogeneity of Dendritic Microstructure Across the Width of a Single Crystal Blade. DOI: 10.1007/s11661-025-07909-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a cylindrical mold made of SS400 steel utilized for slag casting experiments? Explained

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- Why is a stainless steel crucible selected for melting AM60 magnesium alloy? Ensure Alloy Purity and Safety

- What are the primary functions of a quartz tube reactor? Enhance Hydrogen Production and Induction Efficiency

- What functions do high-purity graphite crucibles serve in tantalum carbide synthesis? Essential Thermal & Chemical Roles

- What is the function of ceramic balls within a box furnace? Improve Coke Graphitization & System Safety

- What is the purpose of a PTFE-lined autoclave in TiO2 synthesis? Unlock Precision Nano-material Growth

- What role does a copper mold play in the formation of glass samples? Master Rapid Quenching & Amorphous Solidification