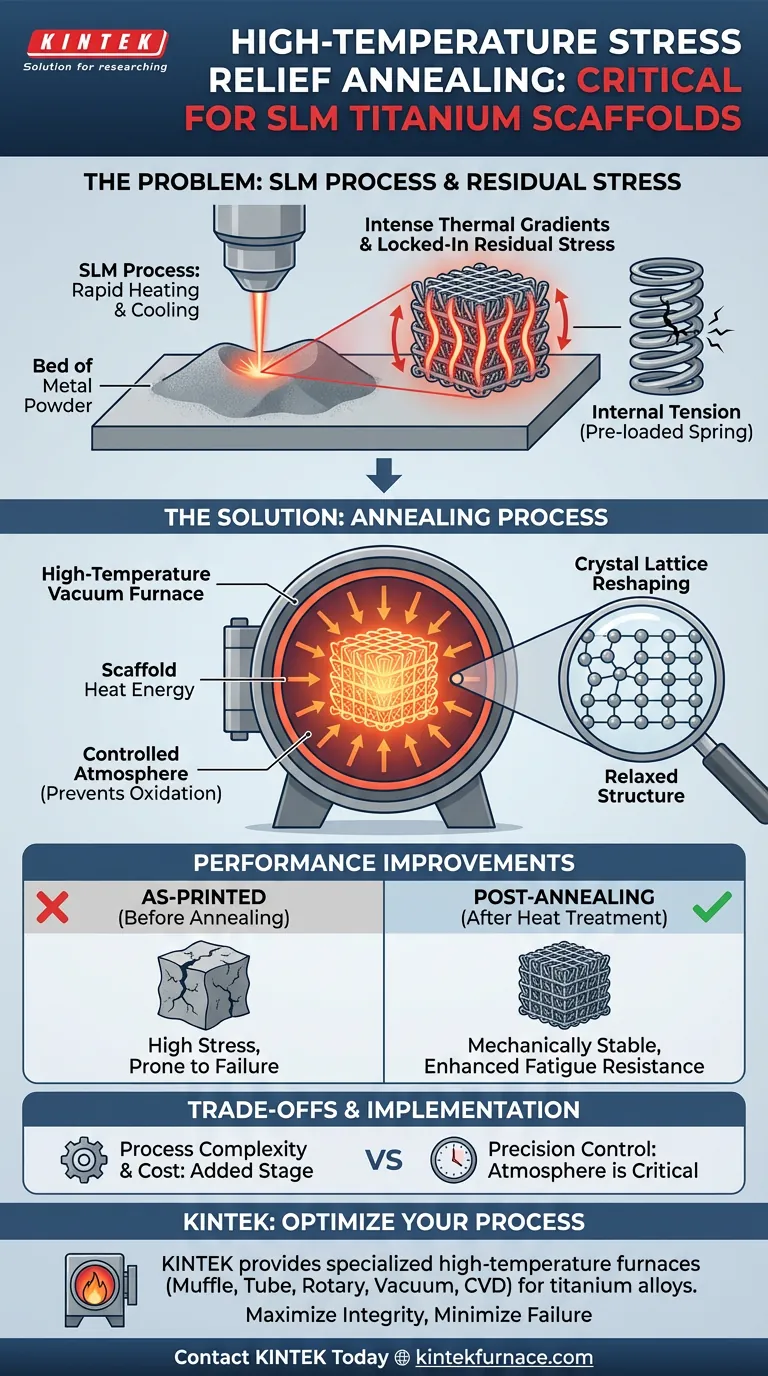

High-temperature stress relief annealing is essential because the Selective Laser Melting (SLM) process inherently creates extreme thermal gradients that lock dangerous residual stresses inside the titanium structure. Without this specific heat treatment, the scaffold remains mechanically unstable and prone to failure under cyclic loading due to these internal tensions.

The rapid heating and cooling of SLM creates internal forces that compromise the material. High-temperature annealing eliminates this "locked-in" stress by reshaping the crystal lattice, transforming a printed shape into a durable, fatigue-resistant component.

The Hidden Dangers of the SLM Process

Intense Thermal Gradients

The SLM process builds components by melting metal powder with a high-energy laser. This creates rapid, localized heating followed by nearly instantaneous cooling.

Consequently, different areas of the scaffold cool at different rates. These intense thermal gradients are the root cause of the material's internal instability.

Accumulation of Residual Stress

As the material tries to contract during uneven cooling, it is restrained by the surrounding solid material.

This conflict generates significant internal residual stresses. If left untreated, these stresses act like a pre-loaded spring, waiting to release energy in the form of cracks or warping.

How Annealing Restores Integrity

The Controlled Environment

To be effective, stress relief must occur in a high-temperature vacuum or a controlled atmosphere furnace.

This specific environment is critical for titanium alloys. It prevents oxidation and surface contamination while the material is vulnerable at high heat.

Reshaping the Crystal Lattice

The application of heat provides energy to the atoms within the alloy. This allows the microstructure to reorganize itself.

The process reshapes the internal crystal lattice of the material. This realignment relaxes the tension built up during printing, effectively erasing the "memory" of the harsh thermal gradients.

Critical Performance Improvements

Mechanical Stability

Once the residual stresses are eliminated, the scaffold achieves true mechanical stability.

The component is no longer fighting against its own internal forces. This ensures it maintains its shape and structural integrity when subjected to external loads.

Enhanced Fatigue Resistance

Perhaps the most critical benefit is the improvement in fatigue resistance.

Residual stresses are prime initiation sites for cracks. by removing them, you significantly extend the lifespan of the scaffold, allowing it to endure repeated stress cycles without failure.

Understanding the Trade-offs

Process Complexity and Cost

Implementing a high-temperature vacuum cycle adds a distinct step to the manufacturing workflow.

This requires specialized furnace equipment and extends the total production time. It changes SLM from a "print-and-go" process to a multi-stage manufacturing chain.

Precision Control Requirements

The annealing process is not merely about getting the part hot; it requires precise control over the atmosphere.

Improper control in the furnace can lead to surface contamination or oxidation. The "controlled atmosphere" mentioned in the reference is a strict requirement, not a suggestion, adding to the operational overhead.

Optimizing Post-Processing for Durability

To ensure your titanium scaffolds perform as intended, you must view annealing as an integral part of the manufacturing process, not an optional after-thought.

- If your primary focus is dimensional accuracy: Prioritize annealing to release internal tension, ensuring the part does not warp or distort after being removed from the build plate.

- If your primary focus is long-term reliability: Verify that the annealing cycle is sufficient to fully reshape the crystal lattice, maximizing fatigue resistance for cyclic loading.

Annealing is the bridge that takes a titanium part from a printed prototype to a reliable engineering component.

Summary Table:

| Factor | SLM Process (As-Printed) | Post-Annealing (Heat Treated) |

|---|---|---|

| Internal Stress | High (Residual Stress) | Low (Stress Relieved) |

| Microstructure | Distorted Crystal Lattice | Reorganized/Stabilized |

| Stability | Prone to Cracking/Warping | Dimensionally Stable |

| Fatigue Life | Reduced (Crack Initiation Risk) | Significantly Enhanced |

| Surface Quality | Variable | Protected (in Vacuum/Controlled Atmosphere) |

Maximize the Integrity of Your 3D-Printed Components

Don't let residual stress compromise your innovation. KINTEK provides the specialized high-temperature furnace technology required to transform raw SLM prints into high-performance engineering components.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to provide the controlled atmospheres and uniform heating essential for titanium alloys. Whether you need a standard setup or a customized solution for unique scaffold geometries, our team is ready to support your manufacturing excellence.

Contact KINTEK Today to Optimize Your Heat Treatment Process

Visual Guide

References

- Ming-Chan Lee, Yow‐Ling Shiue. Design, Manufacture, and Characterization of a Critical-Sized Gradient Porosity Dual-Material Tibial Defect Scaffold. DOI: 10.3390/bioengineering11040308

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the role of an atmosphere sintering furnace in the MLM process? Master CNT/Cu Composite Preparation

- Why are high-temperature vacuum or atmosphere furnaces used for annealing metal silicide? Unlock Peak Thermal Stability

- How does a reactive rapid thermal annealing furnace contribute to phosphosulfide crystallization? Expert Insights

- What are the two main purposes of controlling the atmosphere in a lab furnace? Master Material Protection and Transformation

- Why is it necessary to use a high-purity argon gas protective atmosphere? Ensure Precision in Brazing Filler Melting

- What are the different configurations available for inert atmosphere furnaces? Find Your Perfect Match for Heat Treatment

- What factors should be considered when choosing a controlled atmosphere furnace? Ensure Optimal Performance for Your Materials

- What factors should be considered when purchasing an inert oven? Ensure Optimal Performance and Safety