When purchasing an inert oven, the primary factors to evaluate are its size and capacity, operational temperature range, compatibility with specific inert gases, and the sophistication of its control and safety systems. These specifications determine the oven's ability to protect sensitive materials from atmospheric reactions like oxidation during heating processes.

The core challenge is not simply buying an oven, but acquiring a system capable of creating and maintaining a specific level of atmospheric purity. Your focus should be on how the oven's features—its construction, purging system, and sensors—work together to reliably remove oxygen and moisture to meet your process requirements.

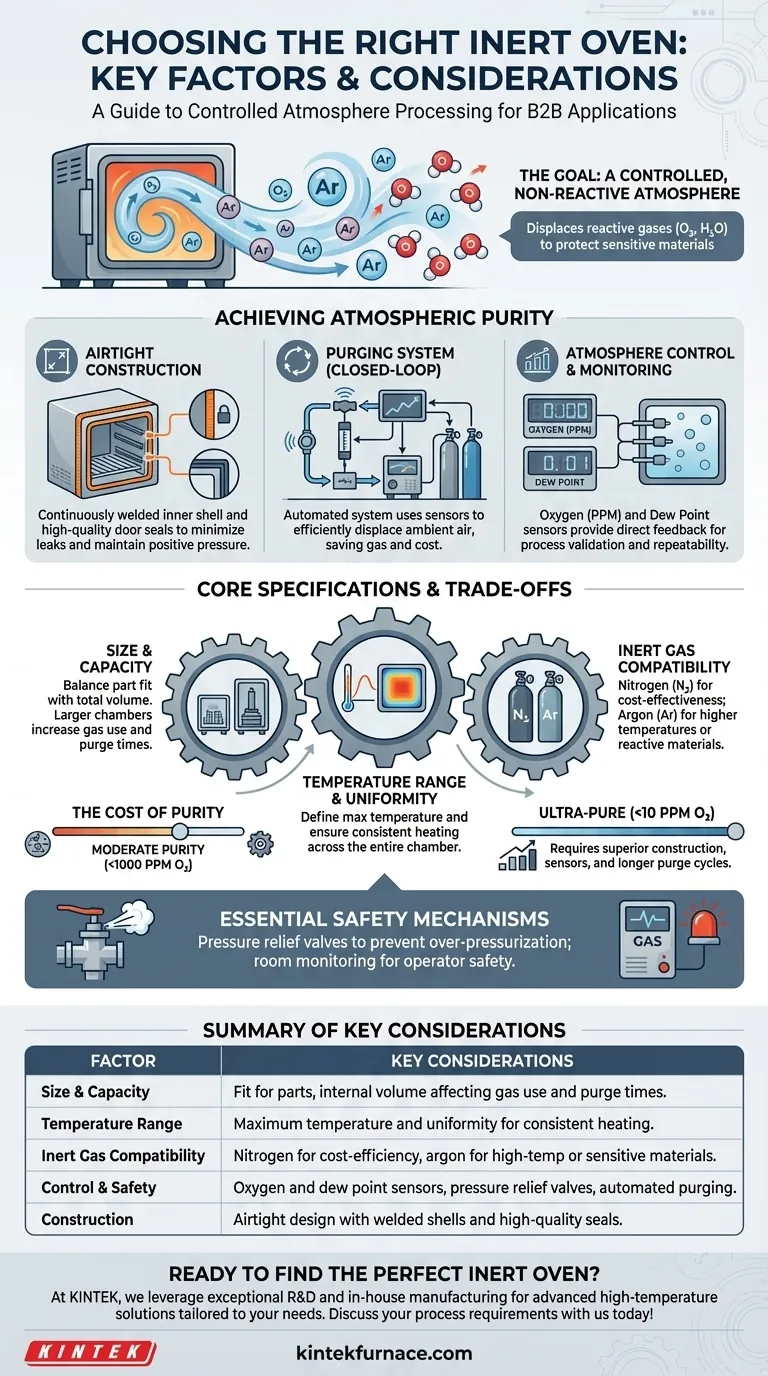

The Goal: A Controlled, Non-Reactive Atmosphere

An inert oven's purpose is to displace the reactive gases in a standard atmosphere (primarily oxygen and water vapor) with a non-reactive gas like nitrogen or argon. Understanding how an oven achieves this is critical to making an informed choice.

Airtight Construction: The First Line of Defense

The oven's ability to hold a positive pressure without leaking is its most fundamental feature. Even a small leak will contaminate the inert atmosphere and compromise your process.

Look for a continuously welded inner shell. This design minimizes potential leak paths compared to folded or riveted seams. High-quality door seals are equally important for maintaining chamber integrity over thousands of cycles.

The Purging System: Removing Contaminants

A purging system introduces the inert gas to displace the ambient air. A basic system may have a simple manual valve, while advanced systems offer precise control.

A closed-loop gas flow control system is highly desirable. It uses sensors to automate the purging process, ensuring the target oxygen level is met efficiently, which saves significant amounts of gas and reduces operational costs.

Atmosphere Control: Monitoring and Measurement

You cannot control what you do not measure. The oven’s sensors are the key to process validation and repeatability.

Oxygen sensors provide direct feedback on the purity of the internal atmosphere, often measured in parts per million (PPM). For processes sensitive to moisture, a dew point sensor is essential for monitoring and controlling humidity levels.

Core Specifications to Match Your Process

Once you understand how an inert atmosphere is achieved, you can evaluate the oven's core specifications in the context of your specific application.

Size and Internal Capacity

Consider not only if your parts will fit but also the total internal volume. A larger chamber requires more inert gas and longer purge times to reach the desired purity level, directly impacting cycle time and operational cost.

Temperature Range and Uniformity

Define the maximum temperature your process requires. More importantly, inquire about temperature uniformity—the specification that guarantees the temperature is consistent across the entire chamber. Poor uniformity can lead to inconsistent product quality.

Inert Gas Compatibility

Most inert ovens are designed for Nitrogen (N2), which is cost-effective for the majority of applications. For processes requiring higher temperatures or working with materials reactive to nitrogen, Argon (Ar) is the common alternative, though it is more expensive.

Understanding the Trade-offs and Safety

An inert oven is a complex piece of equipment with inherent trade-offs between performance, cost, and safety.

The Cost of Purity

Achieving an ultra-pure atmosphere (e.g., <10 PPM of O2) is exponentially more difficult and expensive than a moderately pure one (e.g., <1000 PPM). This requires superior construction, more advanced sensors, and longer, more gas-intensive purge cycles. Be realistic about the purity your process truly needs.

Operational Complexity

These are not simple on/off appliances. Operating an inert oven correctly requires developing a validated process and training operators on the proper sequencing of purging, heating, and cooling cycles to ensure both product quality and safety.

Essential Safety Mechanisms

Because the oven is pressurized with inert gas, safety is paramount. A pressure relief valve is non-negotiable to prevent dangerous over-pressurization. Gas monitoring systems for the surrounding room are also critical to protect operators from asphyxiation risk in the event of a significant leak.

Making the Right Choice for Your Application

Evaluate your choices by aligning the oven’s capabilities with your primary process goal.

- If your primary focus is high-volume production: Prioritize ovens with automated, efficient gas purging systems and robust construction to minimize cycle time and gas consumption.

- If your primary focus is R&D or processing highly sensitive materials: Invest in a system with superior airtight construction and advanced oxygen and moisture sensors for maximum atmospheric control and data logging.

- If your primary focus is process consistency: Emphasize ovens with certified temperature uniformity and closed-loop controls to ensure every batch is processed under identical conditions.

Ultimately, selecting the right inert oven comes from clearly defining the atmospheric conditions your materials require and choosing the equipment that can deliver those conditions reliably and safely.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Size and Capacity | Fit for parts, internal volume affecting gas use and purge times |

| Temperature Range | Maximum temperature and uniformity for consistent heating |

| Inert Gas Compatibility | Nitrogen for cost-efficiency, argon for high-temp or sensitive materials |

| Control and Safety | Oxygen and dew point sensors, pressure relief valves, automated purging |

| Construction | Airtight design with welded shells and high-quality seals |

Ready to find the perfect inert oven for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your process with reliable, safe, and efficient equipment!

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why are inert atmosphere furnaces important for graphite and carbon products? Prevent Oxidation and Ensure High-Performance Results

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity