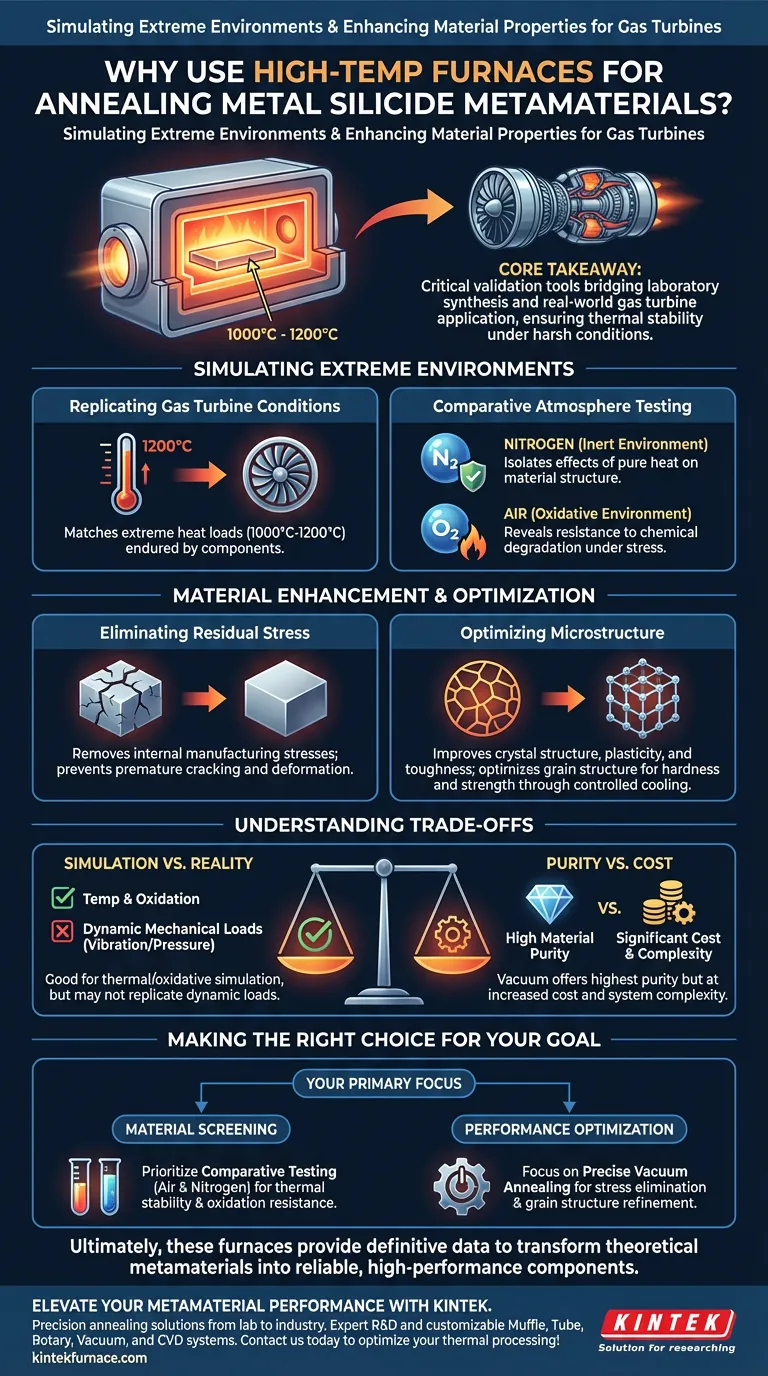

High-temperature vacuum and atmosphere furnaces are primarily used to simulate the extreme operating conditions of gas turbines, specifically temperatures ranging from 1000°C to 1200°C. By subjecting metal silicide metamaterials to these controlled environments, researchers can verify their thermal stability and screen for materials capable of withstanding severe thermal and oxidative stresses.

Core Takeaway These furnaces serve as critical validation tools that bridge the gap between laboratory synthesis and real-world application. They allow for comparative testing in both inert and oxidative atmospheres to ensure a material can survive the harsh environments found in high-performance machinery like gas turbines.

Simulating Extreme Environments

To determine if a metal silicide metamaterial is viable for industrial use, it must be tested against the specific threats it will face in operation.

Replicating Gas Turbine Conditions

The primary function of these furnaces is to reproduce the harsh thermal environment of a gas turbine engine.

The furnaces operate at temperatures between 1000°C and 1200°C, matching the extreme heat loads these components must endure.

Comparative Atmosphere Testing

A crucial aspect of this process is the ability to switch between different atmospheric conditions to test specific vulnerabilities.

Experiments are conducted in nitrogen to simulate an inert environment, isolating the effects of pure heat on the material's structure.

Comparative experiments are then conducted in air to simulate an oxidative environment, revealing how the material resists chemical degradation under stress.

Material Enhancement and Optimization

Beyond simple stress testing, the annealing process within these furnaces actively improves the physical properties of the material.

Eliminating Residual Stress

The annealing process effectively removes internal residual stresses accumulated during the initial manufacturing or shaping of the material.

By relieving these stresses, the process prevents premature cracking or deformation when the material is eventually placed in service.

Optimizing Microstructure

Vacuum annealing facilitates the improvement of the material's crystal structure, plasticity, and toughness.

Precise control over cooling rates allows researchers to optimize the grain structure, which directly enhances the material's hardness and overall mechanical strength.

Understanding the Trade-offs

While high-temperature furnaces are essential for validation, it is important to understand the limitations of the testing process.

Simulation vs. Reality

While furnaces simulate temperature and oxidation well, they may not perfectly replicate the dynamic mechanical loads (vibration and pressure) of a live turbine engine.

Purity vs. Cost

Vacuum environments offer the highest material purity by preventing unwanted reactions, but they represent a significant cost and complexity increase compared to standard heat treatment methods.

Making the Right Choice for Your Goal

The specific way you utilize these furnaces depends on whether you are in the early screening phase or the final processing phase.

- If your primary focus is Material Screening: Prioritize comparative testing in both air and nitrogen to differentiate between thermal stability and oxidation resistance.

- If your primary focus is Performance Optimization: Focus on precise vacuum annealing to eliminate residual stress and refine the grain structure for maximum toughness.

Ultimately, these furnaces provide the definitive data needed to transform a theoretical metamaterial into a reliable, high-performance component.

Summary Table:

| Feature | Vacuum/Atmosphere Annealing Benefit |

|---|---|

| Temperature Range | 1000°C to 1200°C (Simulates gas turbine environments) |

| Atmosphere Control | Nitrogen (Inert/Thermal stability) vs. Air (Oxidative stress) |

| Structural Integrity | Eliminates internal residual stresses and prevents cracking |

| Microstructure | Optimizes grain structure for enhanced plasticity and toughness |

| Material Purity | Vacuum prevents unwanted chemical reactions and contamination |

Elevate Your Metamaterial Performance with KINTEK

Precision annealing is the bridge between lab-scale synthesis and industrial-grade reliability. At KINTEK, we understand the extreme demands of high-performance machinery. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific research or production requirements.

Whether you are screening for oxidation resistance or optimizing crystal structures for maximum toughness, our high-temperature lab furnaces provide the precise control you need to transform theoretical materials into reliable components.

Ready to optimize your thermal processing? Contact us today to find the perfect furnace solution for your lab!

Visual Guide

References

- Next Generation of Thermal Barrier Coatings with High Temperature Metal‐Silicide Metamaterials. DOI: 10.1002/adom.202501827

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is argon gas used for 800HT alloy experiments? Protect Material Integrity with Inert Atmosphere Control

- What is the atmosphere of a heat treatment furnace? Master the Key to Superior Metal Properties

- Why Use a Reducing Atmosphere Furnace for Na4Fe3(PO4)2(P2O7)? Ensure Fe2+ Stability and Battery Performance

- What is the role of a benchtop drying oven in the preparation of Cu/TiO2/ZSM-5 catalysts? Ensure Optimal Dispersion

- What problems arise when ordinary metal materials are heated in an air furnace? Avoid Oxidation and Embrittlement

- How is the protective atmosphere box furnace applied in metal heat treatment? Enhance Metal Properties with Controlled Atmospheres

- What role does an atmosphere box furnace play in material synthesis and preparation? Unlock Precision in Advanced Material Creation

- Why is an Ar/H2 reducing atmosphere required for Si/Al2O3/RGO calcination? Protect Battery Material Integrity