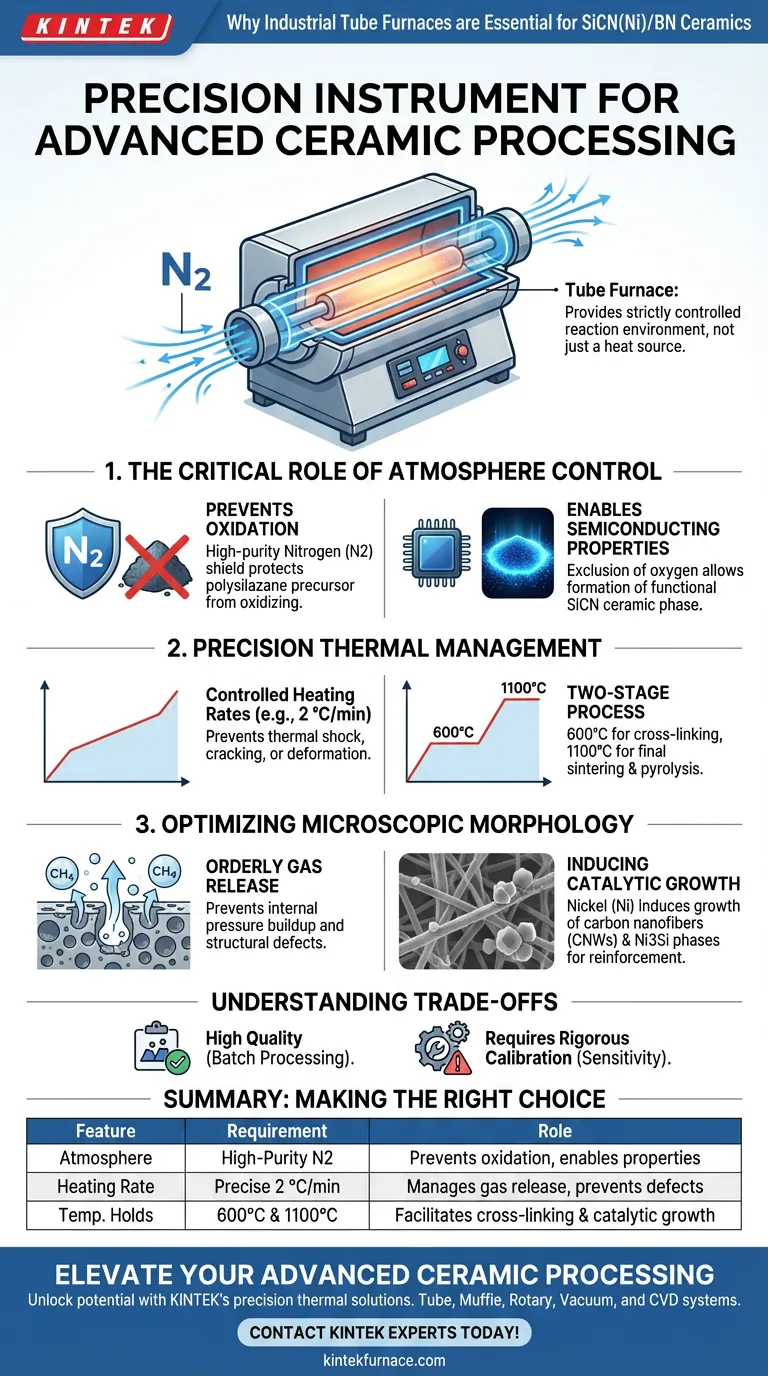

An industrial tube furnace is essential for processing SiCN(Ni)/BN ceramics because it provides a strictly controlled reaction environment that standard kilns cannot match. Specifically, it enables the precise regulation of heating rates and maintains a high-purity nitrogen atmosphere to prevent oxidation. This control is mandatory to successfully convert polysilazane precursors into a functional semiconducting SiCN ceramic phase.

The tube furnace serves as a precision instrument rather than a simple heat source. It facilitates a complex, two-stage pyrolysis process that allows for the orderly release of gases and the catalytic growth of carbon nanofibers, ensuring the final material achieves its optimal microscopic morphology.

The Critical Role of Atmosphere Control

Preventing Material Oxidation

The primary function of the tube furnace in this context is to maintain a high-purity nitrogen (N2) protective atmosphere.

Without this shielding gas, the polysilazane precursor would oxidize during pyrolysis rather than converting into the desired ceramic phase.

Enabling Semiconducting Properties

The exclusion of oxygen is critical for the chemical transformation of the precursor.

By ensuring the reaction occurs in an inert environment, the furnace allows the formation of the SiCN ceramic phase, which is responsible for the material's specific semiconducting properties.

Precision Thermal Management

Controlled Heating Rates

Successful conversion requires a slow, steady rise in temperature, specifically at rates such as 2 °C per minute.

The industrial tube furnace allows for this granular control, preventing thermal shock or rapid reactions that could crack or deform the ceramic body.

Executing a Two-Stage Process

The conversion of SiCN(Ni)/BN ceramics is not a linear heating event; it requires a programmable two-stage heating process.

The furnace effectively manages a hold at 600 °C for steady cross-linking, followed by a ramp to 1100 °C for final sintering and pyrolysis.

Optimizing Microscopic Morphology

Managing Gas Release

During pyrolysis, small molecule gases like methane (CH4) are generated within the material.

The precise temperature control program of the tube furnace ensures these gases are released in an orderly fashion, preventing internal pressure buildup that could lead to structural defects.

Inducing Catalytic Growth

The specific thermal environment allows the nickel (Ni) component to act as a catalyst during the heating cycle.

Under these strictly maintained conditions, nickel induces the in-situ growth of carbon nanofibers (CNWs) and Ni3Si crystalline phases, which are vital for reinforcing the ceramic's structure.

Understanding the Trade-offs

Batch Processing Limitations

While tube furnaces offer superior environmental control, they are typically batch-processing units with limited volume.

This ensures high quality for specialized materials like SiCN(Ni)/BN but may restrict throughput compared to continuous belt furnaces used for lower-grade ceramics.

Calibration Sensitivity

The strict requirements for heating rates (e.g., 2 °C/min) and atmosphere purity mean the equipment requires rigorous calibration.

Inaccurate sensors or leaks in the tube seals can lead to immediate oxidation or incomplete pyrolysis, rendering the batch unusable.

Making the Right Choice for Your Goal

To ensure the successful fabrication of SiCN(Ni)/BN ceramics, align your equipment settings with your specific material objectives:

- If your primary focus is Phase Purity: Ensure the furnace is certified for high-vacuum or high-purity positive pressure operations to maintain the integrity of the nitrogen atmosphere.

- If your primary focus is Structural Integrity: Prioritize a furnace with advanced programmable controllers to strictly enforce the 2 °C/min heating rate and the multi-stage temperature holds.

Ultimately, the industrial tube furnace is not just a heater, but the enabling tool that defines the chemical and structural reality of advanced ceramic composites.

Summary Table:

| Feature | Requirement | Role in Ceramic Processing |

|---|---|---|

| Atmosphere | High-Purity Nitrogen (N2) | Prevents oxidation and enables semiconducting properties |

| Heating Rate | Precise 2 °C/min | Manages gas release (CH4) and prevents structural defects |

| Temperature Holds | 600°C & 1100°C Stages | Facilitates cross-linking and catalytic growth of carbon nanofibers |

| System Type | Controlled Tube Furnace | Ensures high-purity environment vs. standard kilns |

Elevate Your Advanced Ceramic Processing

Unlock the full potential of your SiCN(Ni)/BN ceramics with KINTEK’s precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems tailored to your specific research or production needs. Whether you require strict atmosphere control or programmable multi-stage heating, our customizable furnaces ensure your materials achieve optimal microscopic morphology and purity.

Ready to optimize your heat treatment? Contact KINTEK Experts Today to discuss your unique laboratory or industrial requirements!

Visual Guide

References

- Yanchun Tong, Shigang Wu. Enhanced electromagnetic wave absorption properties of SiCN(Ni)/BN ceramics by <i>in situ</i> generated Ni and Ni<sub>3</sub>Si. DOI: 10.1039/d3ra07877a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why Use Nitrogen in Lab Tube Furnaces for LFP Relithiation? Ensure Superior Battery Material Restoration

- Why is heat treatment in a tube furnace or muffle furnace required after synthesizing magnesium hydroxide nano-precursors via electrochemical methods? Unlock the Full Potential of Your MgO Nanomaterials

- How do Quartz Tube Furnaces support controlled atmosphere experiments? Master Precise Material Synthesis

- What benefits do high temperature tube furnaces offer? Achieve Precise, Uniform Heat for Advanced Materials

- What is the primary function of a Drop Tube Furnace? Master Single-Particle Solid Fuel Ignition Analysis

- Why is a quartz tube fixed-bed reactor ideal for VOC/Hydrogen combustion? Unlock High-Temp Precision & Stability

- What factors should be considered when selecting a horizontal electric furnace? Ensure Precision and Efficiency for Your Lab

- What are the temperature capabilities of tube furnaces? Find the Perfect Heat for Your Process