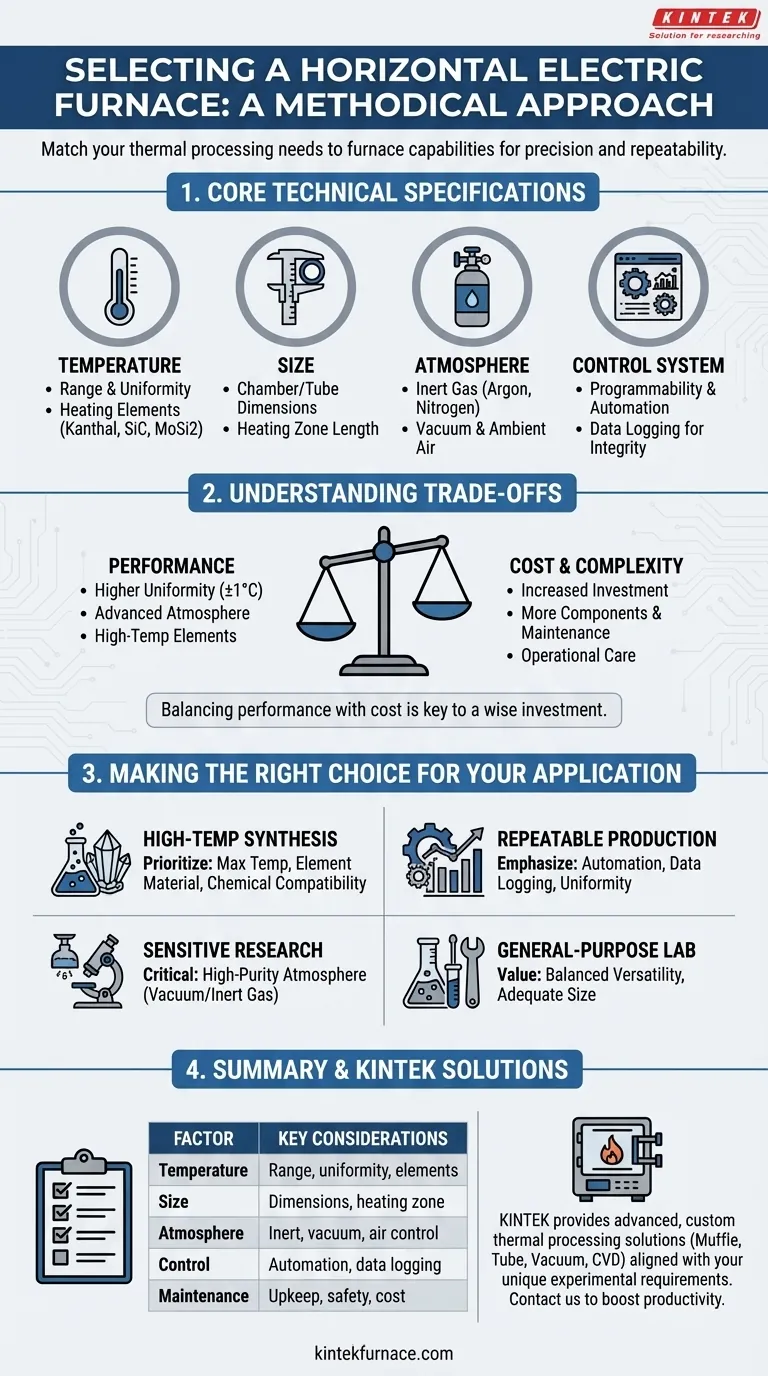

At its core, selecting a horizontal electric furnace requires a methodical evaluation of your specific thermal processing needs against the furnace's capabilities. The most critical factors to consider are the required temperature range and uniformity, the physical size of the chamber or tube, the necessity for atmosphere control (such as inert gas or vacuum), and the sophistication of the control system.

The goal is not simply to buy a furnace that gets "hot enough." The real objective is to invest in a system that guarantees the thermal precision, environmental control, and process repeatability required for your specific material or application.

Core Technical Specifications: Matching the Furnace to Your Process

The primary function of any furnace is to deliver controlled heat. Your first step is to precisely define the thermal and physical parameters your process demands.

Defining Your Thermal Profile

The most crucial specification is temperature. You must look beyond just the maximum rating.

Temperature range determines the operational limits, while temperature uniformity across the heated zone dictates the consistency of your results. A lack of uniformity can lead to inconsistent material properties or failed experiments.

Sizing for Throughput and Sample Integrity

The physical dimensions of the furnace must accommodate your workload.

Consider the chamber size or tube diameter needed for your samples. Just as important is the heating zone length, which must be long enough to fully contain your sample within the area of uniform temperature.

Controlling the Process Atmosphere

Many modern materials and processes are sensitive to oxygen at high temperatures.

Atmosphere control is a key feature of many horizontal furnaces. This can range from processing in ambient air to using inert gases (like argon or nitrogen) to prevent oxidation, or even creating a vacuum for highly sensitive applications.

The Control System: From Automation to Data Integrity

A furnace is only as good as its control system. This system is the brain of the operation, dictating the precision and repeatability of your thermal cycles.

Programmability and Automation

Modern controllers allow you to program complex thermal profiles with multiple steps, including temperature ramps (heating/cooling rates) and dwells (soaking at a specific temperature).

This automation is essential for ensuring every run is identical, reducing human error and freeing up operator time.

The Importance of Data Logging

For research, quality assurance, or process validation, knowing what happened during a cycle is non-negotiable.

Data logging features record the temperature profile over time, providing an invaluable record for troubleshooting, reporting, and certifying that a process was completed to specification.

Understanding the Trade-offs and Practical Realities

Selecting a furnace involves balancing performance with cost and complexity. Understanding the trade-offs is key to making a wise investment.

Temperature Uniformity vs. Cost

Achieving a highly uniform temperature zone (e.g., ±1°C) requires sophisticated design, multiple heating zones, and advanced controls, which significantly increases cost. You must determine the level of uniformity your process truly requires.

Atmosphere Control Complexity

Adding capabilities for inert gas or vacuum introduces more components like seals, gas flow controllers, and vacuum pumps. These add to the initial cost and create more potential points of failure and maintenance requirements over the furnace's life.

Heating Elements and Longevity

The material of the heating elements (e.g., Kanthal, Silicon Carbide, MoSi2) dictates the furnace's maximum temperature and lifespan. Higher-temperature elements are more expensive and may require more careful operation to maximize their service life.

Ongoing Maintenance and Safety

A furnace is not a "set and forget" appliance. It requires routine maintenance, including temperature sensor calibration, cleaning to prevent contamination, and eventual replacement of heating elements. Proper operator training on safety protocols for heat, high voltage, and compressed gases is also essential.

Making the Right Choice for Your Application

Ultimately, your choice should be guided by your primary application. Use your specific goal to prioritize the features that matter most.

- If your primary focus is high-temperature material synthesis: Prioritize the maximum temperature rating, heating element material, and the chemical compatibility of the tube material (e.g., alumina, quartz).

- If your primary focus is repeatable production: Emphasize the control system's automation capabilities, data logging, and proven temperature uniformity.

- If your primary focus is sensitive materials research: The most critical feature will be high-purity atmosphere control, whether through a vacuum-tight system or precise inert gas flow.

- If your primary focus is general-purpose lab work: A balanced furnace with a versatile temperature range and adequate chamber size, even with simpler controls, will offer the most value.

Choosing the right furnace is an investment in the accuracy and reliability of your future work.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Temperature | Range, uniformity, and heating elements (e.g., Kanthal, SiC) |

| Size | Chamber/tube dimensions and heating zone length |

| Atmosphere | Control for inert gas, vacuum, or ambient air |

| Control System | Programmability, automation, and data logging |

| Maintenance | Routine upkeep, safety protocols, and cost trade-offs |

Ready to enhance your lab's thermal processing with a custom horizontal electric furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental requirements, delivering superior temperature control, repeatability, and efficiency. Contact us today to discuss how we can support your specific application and boost your productivity!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide