The primary function of a vacuum oven at 120 °C is to create a controlled environment that forcibly removes stubborn residual solvents and moisture through negative pressure. While heat provides the energy for evaporation, the vacuum lowers the boiling point of liquids, allowing for the complete extraction of impurities trapped deep within the electrode's porous structure without damaging the material.

Core Takeaway: Heat alone is insufficient for high-performance electrodes; the vacuum environment is the critical variable that ensures the total removal of microscopic impurities. This process secures the mechanical bond of the coating and prevents chemical contaminants from causing battery failure during operation.

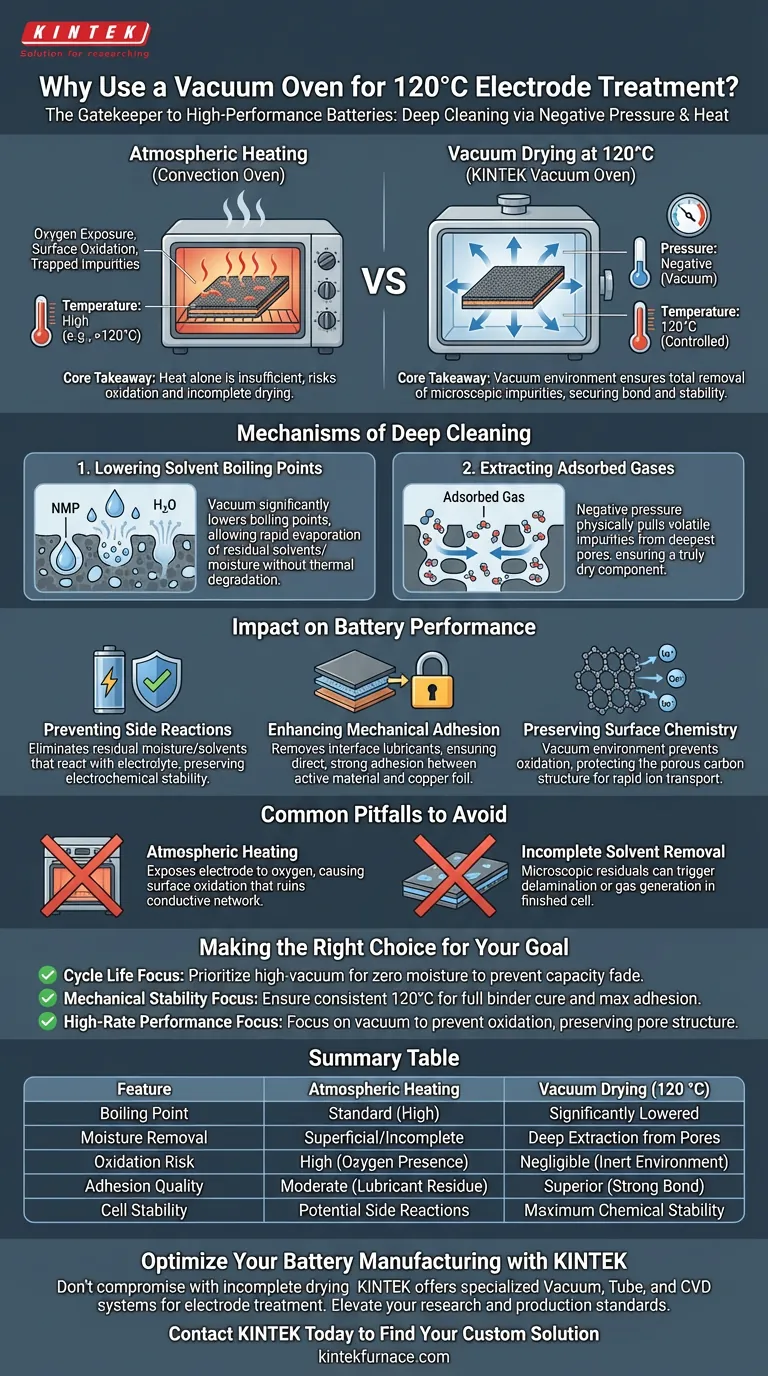

The Mechanisms of Deep Cleaning

Lowering Solvent Boiling Points

The 120 °C temperature target is effective because the vacuum environment significantly lowers the boiling point of residual liquids.

This allows solvents like N-Methyl-2-pyrrolidone (NMP) or moisture from aqueous binders (CMC/SBR) to evaporate rapidly.

Without negative pressure, these liquids might require higher temperatures to remove, which could thermally degrade the electrode components.

Extracting Adsorbed Gases

Electrodes are highly porous materials with complex internal structures.

Simple air drying often leaves trace solvents and gases "adsorbed" (stuck) to the internal walls of these pores.

The negative pressure of the vacuum physically pulls these volatile impurities out from the deepest parts of the active material, ensuring a truly dry component.

Impact on Battery Performance

Preventing Electrochemical Side Reactions

The presence of residual moisture or solvents is chemically dangerous inside a sealed battery cell.

During charge-discharge cycles, these residuals react with the electrolyte, leading to side reactions that consume active lithium and degrade capacity.

Vacuum drying eliminates these reactants, preserving the electrochemical stability of the cell over its lifespan.

Enhancing Mechanical Adhesion

A reliable battery requires the active material to stay firmly attached to the current collector (the copper foil).

Residual solvents at the interface act as a lubricant or barrier, weakening this bond.

By thoroughly removing these traces, the vacuum process ensures direct, strong adhesion between the active material layer and the foil.

Preserving Surface Chemistry

Carbon materials used in electrodes are sensitive to surface changes.

Heating carbon in the presence of air can lead to accidental oxidation, which alters the pore structure and reduces electrochemical activity.

The vacuum environment deprives the chamber of oxygen, protecting the highly developed pore structure of the carbon from oxidative damage.

Common Pitfalls to Avoid

The Risk of Atmospheric Heating

Attempting to achieve this level of dryness using a standard convection oven is a critical error.

Heating without a vacuum exposes the electrode to oxygen, likely causing surface oxidation that ruins the conductive network of the carbon.

Incomplete Solvent Removal

Relying solely on time and temperature often leaves trace amounts of NMP or water deep in the microstructure.

Even microscopic amounts of these residuals can trigger delamination or gas generation inside the finished cell.

Vacuum drying is not merely a faster drying method; it is a quality assurance step that heat alone cannot replicate.

Making the Right Choice for Your Goal

To optimize your electrode manufacturing process, consider your specific performance targets:

- If your primary focus is Cycle Life: Prioritize high-vacuum levels to eliminate every trace of moisture, as this prevents the electrolyte degradation that kills long-term capacity.

- If your primary focus is Mechanical Stability: Ensure the 120 °C temperature is maintained consistently to fully cure the binder system and maximize adhesion to the copper foil.

- If your primary focus is High-Rate Performance: Focus on the vacuum's ability to prevent oxidation, preserving the pristine pore structure required for rapid ion transport.

The vacuum oven is the gatekeeper between a coated foil and a functional, high-performance battery component.

Summary Table:

| Feature | Atmospheric Heating (Convection) | Vacuum Drying (120 °C) |

|---|---|---|

| Boiling Point | Standard (High) | Significantly Lowered |

| Moisture Removal | Superficial/Incomplete | Deep Extraction from Pores |

| Oxidation Risk | High (Oxygen Presence) | Negligible (Inert Environment) |

| Adhesion Quality | Moderate (Lubricant Residue) | Superior (Strong Bond) |

| Cell Stability | Potential Side Reactions | Maximum Chemical Stability |

Optimize Your Battery Manufacturing with KINTEK

Don't compromise your battery's cycle life with incomplete drying processes. Backed by expert R&D and precision manufacturing, KINTEK offers specialized Vacuum, Tube, and CVD systems designed to meet the rigorous demands of electrode treatment.

Whether you need to eliminate residual NMP or prevent carbon oxidation, our customizable high-temperature lab furnaces provide the controlled environment necessary for superior mechanical adhesion and electrochemical stability.

Ready to elevate your research and production standards?

Contact KINTEK Today to Find Your Custom Solution

Visual Guide

References

- Sungwon Hwang. SiOx/C Composite Anode for Lithium-Ion Battery with Improved Performance Using Graphene Quantum Dots and Carbon Nanoparticles. DOI: 10.3390/molecules29112578

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of using semi-coke powder in vacuum reduction for zinc extraction? Boost Diffusion Rates

- Why is Vacuum Consumable Arc Remelting (VAR) required for Ni-W-Co-Ta? Achieve Ultra-Pure Alloy Structural Integrity

- What role does carbonization in a high-temperature furnace play for 2D COF membranes? Enhance Stability & Conductivity

- Why is a long-duration thermal treatment in a UHV furnace necessary for gallium intercalation? Achieve Material Purity

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is the primary use of a vacuum graphitizing furnace? Transforming Carbon into High-Performance Graphite

- What physical conditions do laboratory thermal cycling systems provide for hydride reorientation in zirconium alloys?

- What maintenance tasks are required for drop-bottom quench furnaces? Ensure Peak Performance and Safety