To properly maintain a drop-bottom quench furnace, a systematic approach is required that addresses its four critical systems. This involves regularly cleaning and inspecting the heating elements, monitoring and managing the quenching medium, lubricating all moving parts of the drop mechanism, and consistently checking and calibrating the temperature control systems to ensure process accuracy.

Effective furnace maintenance is not merely about preventing breakdowns. It is about guaranteeing the metallurgical integrity of every part you process by ensuring absolute consistency in your heating, quenching, and mechanical operations.

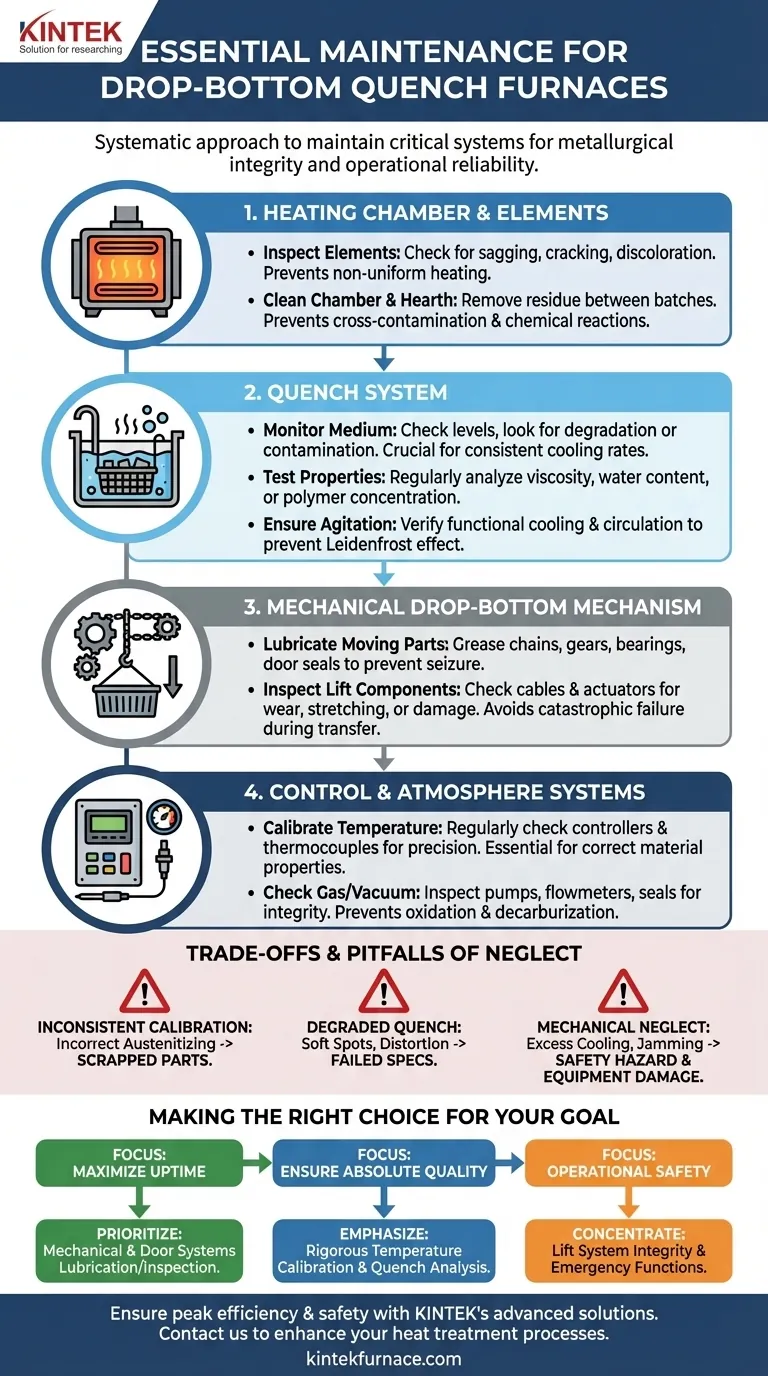

Deconstructing the Maintenance Workflow

A drop-bottom quench furnace integrates thermal, chemical, and mechanical systems. A successful maintenance program treats each system with equal importance, as a failure in one will compromise the entire process.

The Heating Chamber and Elements

The core of the heat treatment process occurs in the heating chamber. Its reliability is paramount.

Inspect heating elements regularly for any signs of physical damage, such as sagging, cracking, or discoloration. Damaged elements lead to non-uniform heating and eventual failure.

Clean the chamber and hearth after use or between batches processing different alloys. This prevents cross-contamination and ensures no residual materials cause stress or unwanted chemical reactions in future cycles.

The Quench System

The rapid cooling phase defines the final properties of the material. The condition of the quench medium is not optional—it's a critical process variable.

Monitor the quenching medium (oil, water, or polymer) for proper levels and signs of degradation or contamination. Contaminants drastically alter cooling rates, leading to inconsistent hardness and potential cracking.

Test the medium's properties according to a set schedule. For oil, this includes viscosity and water content. For polymers, it involves checking the concentration.

Ensure agitation and cooling systems are functional. Proper circulation of the quench medium is essential for uniform cooling and preventing localized vapor barriers (the Leidenfrost effect) that inhibit heat transfer.

The Mechanical Drop-Bottom Mechanism

This system is responsible for the rapid, safe transfer of the workload from the heating chamber to the quench tank. Its failure is a significant safety and operational risk.

Lubricate all moving parts as specified by the manufacturer. This includes chains, gears, bearings, and door seals. Proper lubrication prevents seizure and ensures a smooth, rapid drop.

Inspect lift and transfer components. Check chains, cables, and actuators for wear, stretching, or damage. A failure during transfer can be catastrophic, resulting in lost product and significant equipment damage.

The Control and Atmosphere Systems

These systems are the brain of the furnace, dictating the precision of the entire operation.

Calibrate temperature control systems and thermocouples regularly. Inaccurate temperature readings are a primary cause of rejected parts and incorrect material properties.

Check all gas and vacuum systems if your furnace operates with a controlled atmosphere. Inspect pumps, flowmeters, and seals to ensure atmospheric integrity, which is vital for preventing oxidation and decarburization.

Understanding the Trade-offs and Pitfalls

Ignoring seemingly small maintenance tasks can lead to significant and costly consequences. Understanding these risks is key to justifying a rigorous maintenance schedule.

The Pitfall of Inconsistent Calibration

Deviations in temperature controllers or thermocouples directly translate to incorrect metallurgical outcomes. A furnace set to 1550°F that is actually running at 1520°F may fail to properly austenitize the steel, resulting in an entire batch of scrapped parts.

The Risk of a Degraded Quench

A quench oil contaminated with water or sludge will not provide the rapid, uniform cooling required. This can lead to soft spots, distortion, and a failure to meet hardness specifications, rendering high-value components useless.

The Danger of Mechanical Neglect

A poorly lubricated or worn drop mechanism can hesitate or fail entirely. This can cause the load to cool excessively in transit, ruining the heat treatment, or worse, cause the load to jam or drop uncontrollably, creating a severe safety hazard.

Making the Right Choice for Your Goal

Your maintenance schedule should be tailored to your primary operational drivers. Use this as a guide to focus your efforts.

- If your primary focus is maximizing uptime: Prioritize preventative lubrication and inspection of the mechanical drop mechanism and door systems, as these are common points of physical failure.

- If your primary focus is ensuring absolute product quality: Emphasize rigorous temperature calibration and frequent analysis of your quenching medium to guarantee process repeatability.

- If your primary focus is operational safety: Concentrate on the structural integrity of the lift system, emergency stop functions, and ensuring the drop path is always clear and secure.

Ultimately, consistent maintenance transforms your furnace from a potential liability into a reliable and precise manufacturing asset.

Summary Table:

| System | Key Maintenance Tasks |

|---|---|

| Heating | Inspect elements for damage, clean chamber to prevent contamination |

| Quench | Monitor medium levels, test properties, ensure agitation systems work |

| Mechanical | Lubricate moving parts, inspect lift components for wear |

| Control | Calibrate temperature systems, check gas/vacuum systems for integrity |

Ensure your furnace operates at peak efficiency and safety with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your heat treatment processes and deliver reliable, tailored furnace solutions for your lab!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation