In modern dentistry, the porcelain furnace is the cornerstone of restorative work. It is indispensable because it is the only equipment capable of transforming raw dental ceramics into strong, durable, and highly aesthetic restorations like crowns, bridges, and veneers. The furnace's precise, electronically-controlled heating process is essential for achieving the lifelike appearance and mechanical strength that both clinicians and patients demand.

A porcelain furnace's value lies not merely in its ability to generate heat, but in its programmable control over temperature, time, and atmosphere. This precision is what unlocks the full potential of advanced dental materials, ensuring final restorations are both flawlessly beautiful and functionally robust.

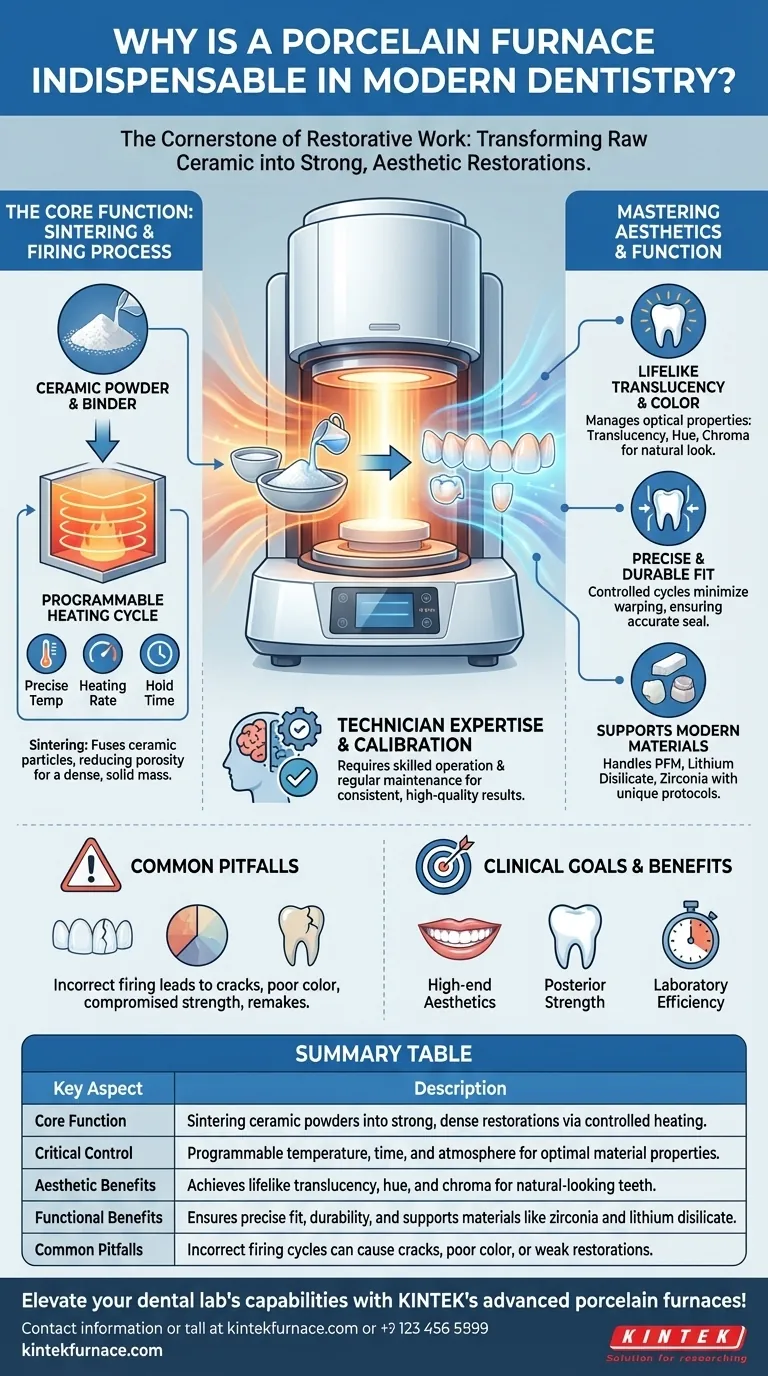

The Core Function: From Ceramic Powder to Precise Prosthesis

A porcelain furnace is fundamentally a specialized, high-temperature oven designed specifically for processing dental ceramics. Its role is to execute a controlled process known as sintering.

The Sintering and Firing Process

Sintering is the process of applying heat to fuse ceramic particles together, reducing porosity and creating a dense, solid mass. This is what gives a dental restoration its final strength and stability.

Modern furnaces manage this through programmable firing cycles. Technicians can set specific temperatures, heating rates, and hold times tailored to the exact material being used.

Why This Control is Critical

Without this precise control, dental ceramics would not reach their optimal state. Improper firing can result in a restoration that is weak, porous, opaque, or dimensionally inaccurate, rendering it clinically useless.

The furnace guarantees that the material matures correctly, achieving the physical and optical properties intended by the manufacturer.

Mastering Aesthetics and Function Through Technology

The furnace is where the art and science of dental restorations converge. Its sophisticated control directly translates into superior clinical outcomes for the patient.

Achieving Lifelike Translucency and Color

A key goal of modern dentistry is to create restorations that are indistinguishable from natural teeth. This requires managing subtle optical properties like translucency, hue, and chroma.

The furnace's ability to follow complex firing schedules allows technicians to develop these specific characteristics within the ceramic, mimicking the natural layers of enamel and dentin.

Ensuring a Precise and Durable Fit

A successful restoration must fit perfectly to prevent gaps that can lead to decay or discomfort. The furnace's controlled heating and cooling cycles minimize the risk of warping or shrinkage.

This precision ensures the final crown, veneer, or bridge seats accurately onto the prepared tooth, creating a durable, long-lasting seal.

Supporting a Wide Range of Modern Materials

Today's dental labs work with a diverse palette of materials. A modern porcelain furnace is versatile enough to handle them all.

This includes traditional porcelain-fused-to-metal (PFM) as well as advanced all-ceramics like lithium disilicate and zirconia, each of which requires a unique firing protocol to achieve its ideal properties.

Common Pitfalls and Operational Realities

While indispensable, the porcelain furnace is a complex piece of equipment where operator skill and technical limitations directly impact the final product. Understanding these factors is crucial for any dental laboratory.

The Impact of an Incorrect Firing Cycle

The most significant pitfall is using an incorrect program. This can lead to a host of problems, including cracks, poor color matching, a chalky or overly glassy surface, and compromised strength.

A single failed firing cycle results in a complete remake, wasting valuable materials, technician time, and delaying patient care.

The Need for Technical Expertise

Operating a furnace is not an automated task. It requires a skilled technician who understands the specific properties of each ceramic material and can select or create the appropriate firing program.

This knowledge is essential to troubleshoot issues and consistently produce high-quality results.

Maintenance and Calibration

For a furnace to remain accurate, it requires regular maintenance and calibration. Temperature drift or a malfunctioning vacuum pump can subtly or catastrophically ruin restorations, making routine checks a necessity for quality control.

Applying This to Your Clinical Goals

The value of a porcelain furnace is directly tied to the clinical and business objectives of the dental practice or laboratory.

- If your primary focus is high-end aesthetic restorations: A furnace with highly customizable programs is non-negotiable for controlling the subtle optical effects in materials like veneers and anterior all-ceramic crowns.

- If your primary focus is strength for posterior restorations: The furnace is essential for ensuring that zirconia and PFM restorations are fully sintered to achieve maximum fracture resistance and longevity.

- If your primary focus is laboratory efficiency: Understanding your furnace's capacity and optimizing firing cycles for different materials is the key to managing workflow, minimizing remakes, and ensuring predictable turnaround times.

Ultimately, the porcelain furnace empowers dental professionals to deliver on the fundamental promise of modern restorative dentistry: creating functional, durable, and beautiful tooth replacements.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Sintering ceramic powders into strong, dense restorations via controlled heating. |

| Critical Control | Programmable temperature, time, and atmosphere for optimal material properties. |

| Aesthetic Benefits | Achieves lifelike translucency, hue, and chroma for natural-looking teeth. |

| Functional Benefits | Ensures precise fit, durability, and supports materials like zirconia and lithium disilicate. |

| Common Pitfalls | Incorrect firing cycles can cause cracks, poor color, or weak restorations. |

Elevate your dental lab's capabilities with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met precisely, delivering durable and aesthetic restorations efficiently. Contact us today to discuss how our products can enhance your clinical outcomes and streamline your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations