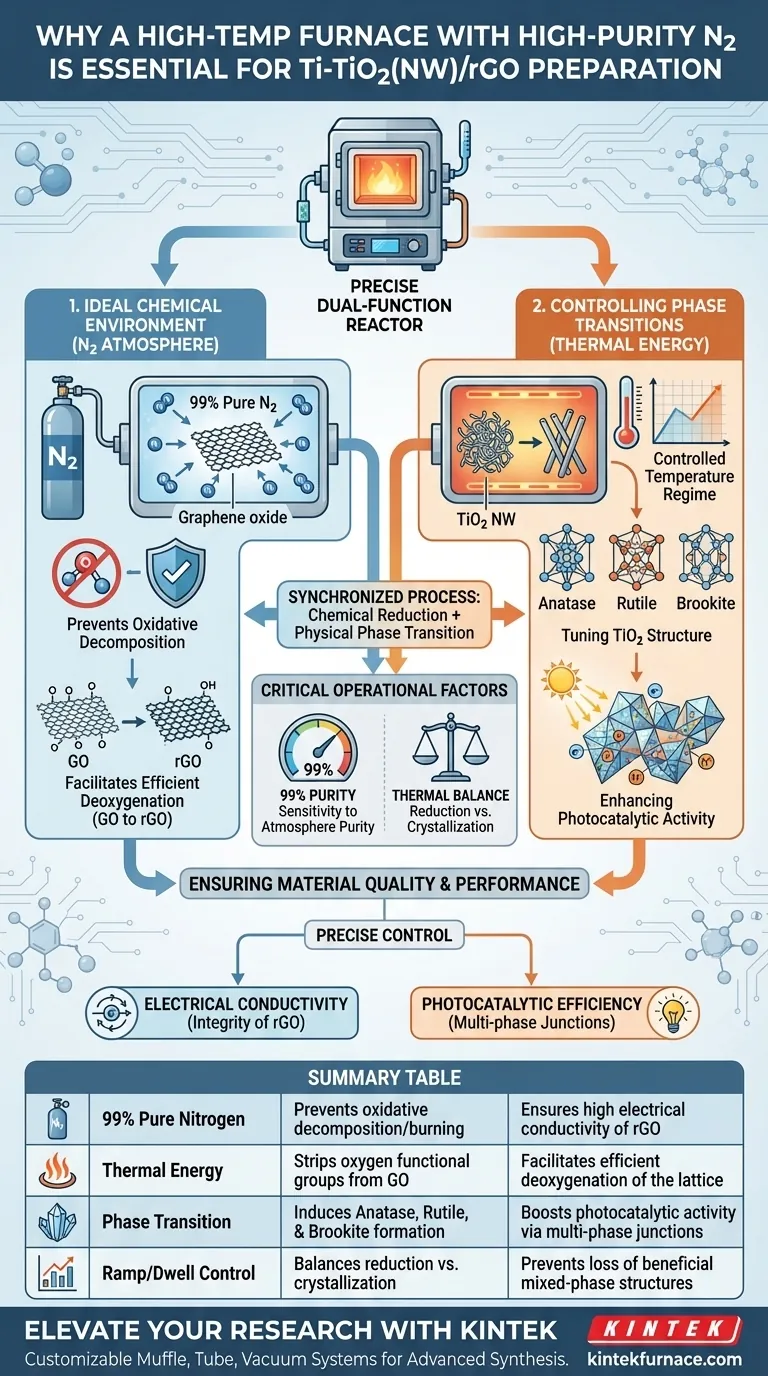

A laboratory high-temperature furnace with high-purity nitrogen control is essential because it serves as a precise dual-function reactor necessary for synthesizing high-performance Ti-TiO2(NW)/rGO. It simultaneously creates the inert environment required to chemically reduce graphene oxide without burning it and provides the thermal energy needed to engineer the specific crystalline structure of the titanium dioxide.

The core function of this equipment is to synchronize chemical reduction with physical phase transition. A 99% pure nitrogen atmosphere prevents oxidative decomposition during the heating process, while the controlled temperature regime creates a critical mix of anatase, rutile, and brookite phases to enhance photocatalytic activity.

Creating the Ideal Chemical Environment

To successfully prepare reduced graphene oxide (rGO), you must subject graphene oxide (GO) to high heat. However, the presence of oxygen during this stage would be catastrophic to the material.

Preventing Oxidative Decomposition

If you attempted this thermal treatment in an uncontrolled atmosphere, the carbon lattice of the graphene oxide would react with ambient oxygen. Instead of reducing into a conductive material, the GO would undergo oxidative decomposition—essentially burning away.

Facilitating Efficient Deoxygenation

The high-purity nitrogen (99%) acts as a protective shield. By displacing oxygen, it creates a reducing atmosphere. This allows the thermal energy to strip oxygen functional groups from the GO sheets efficiently, converting them into stable rGO without compromising the carbon structure.

Controlling Crystalline Phase Transitions

While the atmosphere protects the graphene, the furnace's heat treatment drives critical changes in the titanium dioxide (TiO2) component of the composite.

Tuning the Titanium Dioxide Structure

The thermal energy provided by the furnace is not arbitrary; it dictates the final phase of the TiO2. The process is designed to induce a specific phase transition within the titanium dioxide nanowires (NW).

Enhancing Photocatalytic Activity

The ultimate goal of this heat treatment is to produce a "mixed phase" material containing anatase, rutile, and brookite. The coexistence of these three distinct phases creates multi-phase junctions. These junctions are vital because they facilitate better charge separation, significantly boosting the material's photocatalytic performance.

Understanding the Operational Trade-offs

While this setup is necessary for high-quality synthesis, it introduces specific sensitivities that must be managed.

Sensitivity to Atmosphere Purity

The requirement for 99% purity is strict. Even minor leaks or lower-grade nitrogen can introduce enough oxygen to degrade the rGO or inhibit the proper reduction process, leading to inconsistent electronic properties.

Balancing Thermal Requirements

There is a delicate balance between the temperature needed to reduce GO and the temperature required for the optimal TiO2 phase transition. If the temperature is too low, the GO remains insulating; if it is uncontrolled, you may lose the beneficial mixed-phase structure of the TiO2.

Ensuring Material Quality and Performance

The success of your Ti-TiO2(NW)/rGO preparation depends on how strictly you control these environmental variables.

- If your primary focus is Electrical Conductivity: Prioritize the integrity of the nitrogen purge to ensure maximum deoxygenation of the rGO without defects.

- If your primary focus is Photocatalytic Efficiency: Focus on the precision of the temperature ramp and dwell times to ensure the formation of the anatase-rutile-brookite multi-phase junctions.

Ultimately, the furnace is not just a heating element, but a tuning instrument that defines the chemical stability and physical reactivity of your final composite.

Summary Table:

| Feature | Role in Ti-TiO2(NW)/rGO Preparation | Impact on Material Quality |

|---|---|---|

| 99% Pure Nitrogen | Prevents oxidative decomposition/burning | Ensures high electrical conductivity of rGO |

| Thermal Energy | Strips oxygen functional groups from GO | Facilitates efficient deoxygenation of the lattice |

| Phase Transition | Induces Anatase, Rutile, & Brookite formation | Boosts photocatalytic activity via multi-phase junctions |

| Ramp/Dwell Control | Balances reduction vs. crystallization | Prevents loss of beneficial mixed-phase structures |

Elevate Your Material Research with KINTEK

Precise control over atmosphere and temperature is the difference between a failed experiment and a breakthrough in Ti-TiO2(NW)/rGO synthesis. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of advanced chemical reduction and phase transition tuning.

Backed by expert R&D and manufacturing, our lab high-temperature furnaces are fully customizable to meet your specific gas purity and thermal regime needs. Ensure the integrity of your graphene composites and photocatalytic materials with our reliable technology.

Ready to optimize your synthesis? Contact KINTEK today for a custom furnace solution.

Visual Guide

References

- Mina-Ionela Morariu, Cornelia Bandas. Heterostructure Based of Ti-TiO2(NW)/rGO Hybrid Materials for Electrochemical Applications. DOI: 10.3390/inorganics13020031

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a high-purity argon atmosphere required during the mechanical milling of cobalt-based superalloy powders?

- What are the key benefits of precise temperature control in a controlled atmosphere furnace? Unlock Superior Quality and Efficiency

- Why are inert gases like nitrogen and argon used in furnaces? Prevent Oxidation and Ensure Material Purity

- What are the main components of a box-type atmosphere furnace? Essential Parts for Precise Thermal Processing

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What is the core function of low-pressure atmosphere control in PFS? Unlock Efficient Plasma Generation

- Why is a reducing atmosphere essential for phosphor synthesis? Unlock High-Efficiency Blue Light Activation

- What are the characteristics of atmosphere furnaces? Unlock Precise Heat Treatment for Superior Materials