At its core, precise temperature control in a controlled atmosphere furnace is the mechanism that guarantees repeatable and predictable material properties. This precision ensures that complex heat treatment processes like annealing, brazing, or sintering achieve their exact metallurgical targets, resulting in higher quality parts, reduced waste, and greater operational efficiency. Without it, the benefits of a controlled atmosphere are fundamentally compromised.

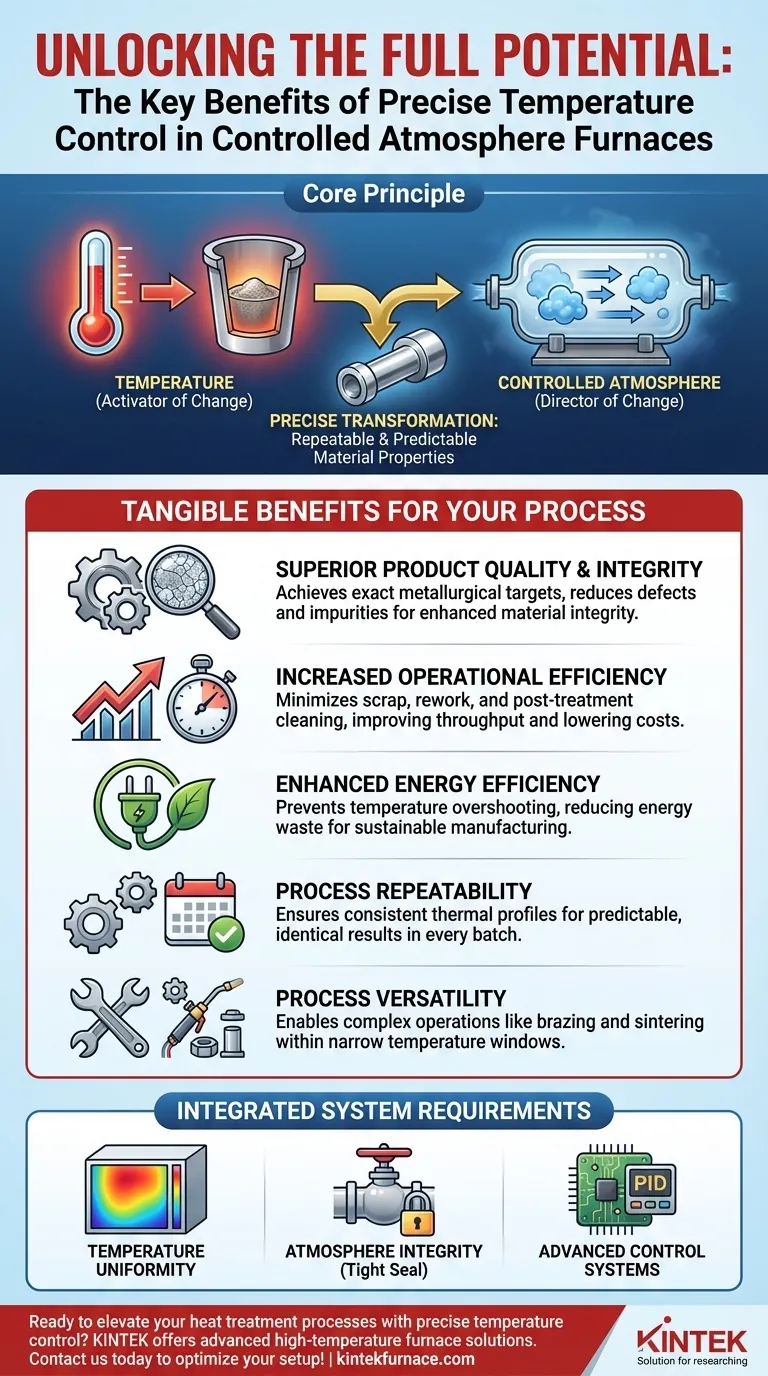

The central takeaway is this: Temperature is the activator of change within a material, while the controlled atmosphere is the director of that change. Precise temperature control ensures the activation happens at the exact rate and to the exact degree required, allowing the atmosphere to perform its function without causing defects or inconsistencies.

The Core Principle: Temperature as the Catalyst for Transformation

A controlled atmosphere furnace is a system where two variables—temperature and atmosphere—work in tandem. While the atmosphere prevents unwanted reactions like oxidation, the temperature drives the desired physical and chemical changes within the material.

Achieving Target Microstructures

Nearly all heat treatment is designed to alter a material's microstructure, which in turn defines its mechanical properties like hardness, ductility, and strength.

These transformations happen at specific temperature thresholds. Too low, and the change is incomplete; too high, and you risk undesirable grain growth or even melting. Precise control ensures you hit and hold the exact temperature needed for the desired outcome.

Ensuring Process Repeatability

For industrial applications, consistency is paramount. A part produced today must be identical to a part produced next month.

Precise temperature control eliminates a major source of process variation. It guarantees that every batch is subjected to the exact same thermal profile, leading to highly predictable and repeatable results.

Enabling Complex Thermal Processes

Processes like brazing and sintering depend on extremely narrow temperature windows. In brazing, the temperature must be high enough to melt the filler metal but low enough not to damage the parent materials.

Only a furnace with precise control can reliably operate within these tight specifications, expanding the range of high-value processes a facility can perform.

How Precision Control Translates to Tangible Benefits

Understanding the core principle reveals how precise temperature control creates direct value in manufacturing and laboratory settings.

Superior Product Quality and Integrity

By hitting exact temperature targets, you prevent common defects. This includes avoiding oxidation, preventing unwanted chemical reactions with the atmosphere, and ensuring the final part meets all mechanical specifications.

This directly translates to improved product quality, fewer impurities, and enhanced material integrity.

Increased Operational Efficiency

When parts are processed correctly the first time, the need for costly and time-consuming secondary operations is dramatically reduced.

There is less scrap, less rework, and no need for post-treatment cleaning to remove oxides. This improves production throughput and lowers overall operating costs.

Enhanced Energy Efficiency

Modern control systems, paired with precise temperature regulation, prevent temperature overshooting. The furnace uses only the energy required to reach and maintain the setpoint.

This contributes to energy efficiency and a more sustainable, cost-effective manufacturing process by minimizing waste.

Understanding the Trade-offs and System Requirements

Precise temperature control is not a standalone feature; it is part of an integrated system. Its effectiveness depends entirely on the quality of the surrounding components.

The Critical Role of Uniformity

A precise temperature reading at a single point is meaningless if there are hot and cold spots elsewhere in the furnace. Temperature uniformity across the entire working volume is essential.

This is achieved through intelligent furnace design, including durable heating elements and systems for uniform atmosphere flow, which ensures consistent gas distribution and heat transfer.

The Necessity of Atmosphere Integrity

Even with perfect temperature control, the process will fail if the protective atmosphere is contaminated. A tight seal is non-negotiable to prevent external air from infiltrating the chamber.

Any leak undermines the entire purpose of the controlled atmosphere, re-introducing oxygen and other contaminants that cause oxidation and other defects.

The Demands on Control Systems

Achieving this level of precision requires advanced control systems. High-quality thermocouples provide accurate feedback, while sophisticated PID controllers (Proportional-Integral-Derivative) manage the heating elements to hold the temperature steady without over- or undershooting the target.

Making the Right Choice for Your Goal

When evaluating a controlled atmosphere furnace, your primary goal will determine where to focus your attention.

- If your primary focus is consistent quality and repeatability: Prioritize systems with documented high temperature uniformity and advanced PID controllers to ensure every part sees the exact same thermal profile.

- If your primary focus is operational efficiency: Look for furnaces with robust seals and efficient insulation, as precise temperature control minimizes energy waste and reduces the need for costly post-processing.

- If your primary focus is process versatility: Confirm the furnace's temperature range and control precision are sufficient to handle the most demanding processes you plan to run, such as multi-stage brazing or sintering advanced ceramics.

Ultimately, mastering temperature is the key to unlocking the full potential of controlled atmosphere heat treatment.

Summary Table:

| Benefit | Description |

|---|---|

| Superior Product Quality | Achieves exact metallurgical targets, reducing defects and impurities for enhanced material integrity. |

| Increased Operational Efficiency | Minimizes scrap and rework, improving production throughput and lowering costs. |

| Enhanced Energy Efficiency | Prevents temperature overshooting, reducing energy waste and supporting sustainable manufacturing. |

| Process Repeatability | Ensures consistent thermal profiles for predictable results in every batch. |

| Versatility in Processes | Enables complex operations like brazing and sintering within narrow temperature windows. |

Ready to elevate your heat treatment processes with precise temperature control? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, delivering superior quality, efficiency, and repeatability. Contact us today to discuss how we can optimize your laboratory or manufacturing setup!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results