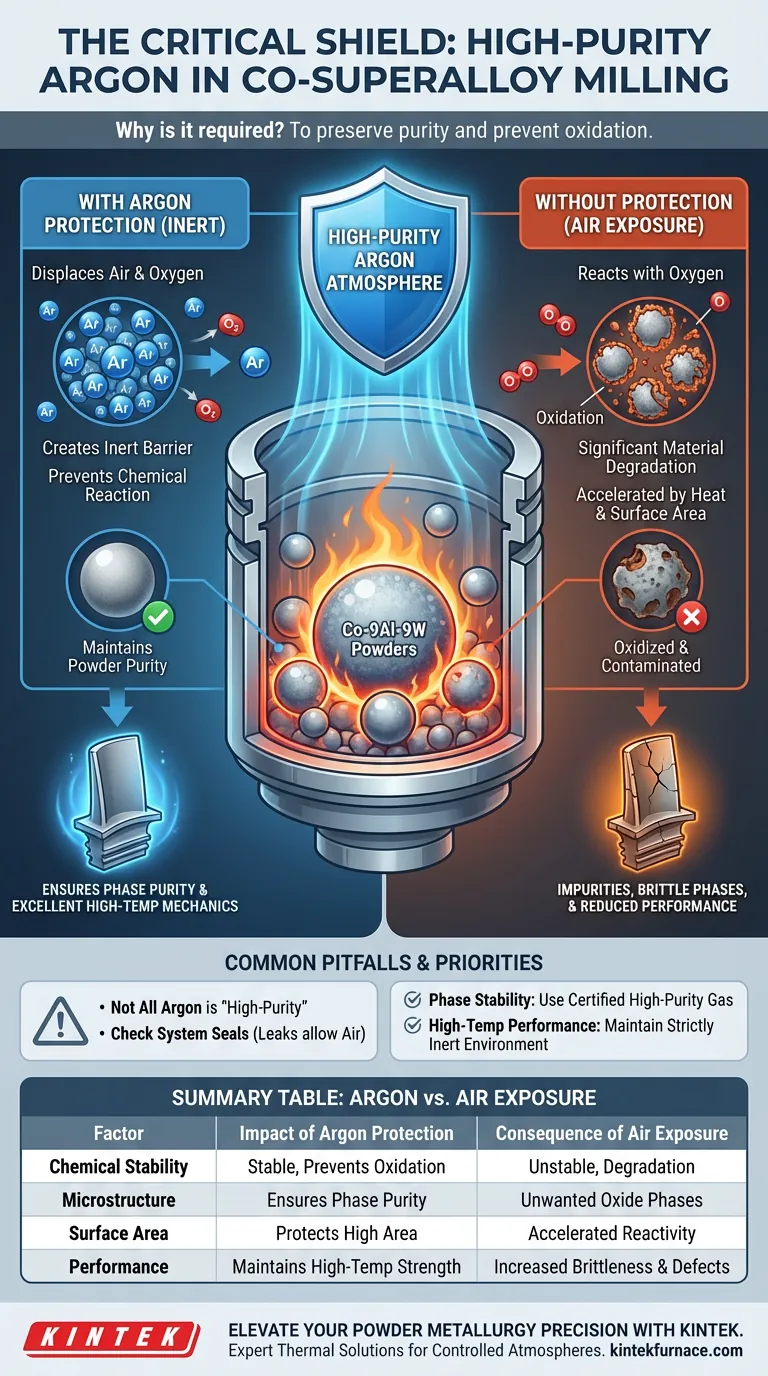

High-purity argon acts as a critical protective shield. During the mechanical milling of cobalt-based superalloy powders (specifically Co-9Al-9W), this inert atmosphere prevents the raw material from chemically reacting with oxygen in the air. Without this protection, the powders would suffer significant oxidation, effectively ruining the material's properties before consolidation even begins.

Core Insight: The primary function of the argon atmosphere is to preserve powder purity during the high-energy milling process. This protection is strictly required to ensure the final sintered components achieve the correct phase purity and maintain excellent mechanical properties at high operating temperatures.

The Mechanics of Contamination

Preventing Chemical Reactions

Cobalt-based superalloy powders are chemically active. If exposed to standard air during milling, they will readily react with oxygen.

The argon atmosphere displaces the air, creating an inert environment. This isolation effectively blocks the oxidation pathway that would otherwise degrade the powder.

The Role of Milling Duration

Mechanical milling is often a long-term process. The longer the material is processed, the higher the probability of exposure to environmental contaminants.

High-purity argon maintains a consistent, non-reactive barrier throughout the entire duration of the milling cycle, neutralizing the risk associated with extended processing times.

Counteracting Surface Area and Heat

While the primary reference focuses on the chemical reaction, it is important to understand the physical state of the powder.

Milling creates high specific surface areas and generates heat through impact. These two factors—heat and increased surface exposure—significantly accelerate chemical reactivity, making the protective argon atmosphere indispensable.

Impact on Final Component Quality

Ensuring Phase Purity

The ultimate goal of milling these powders is to prepare them for sintering into solid components.

If the powder oxidizes during milling, it introduces impurities that alter the microstructure. Using argon ensures that the phase purity of the final component is dictated by the alloy design, not by accidental contamination.

Preserving High-Temperature Mechanics

Cobalt-based superalloys are valued for their performance under extreme heat.

Oxidation acts as a defect. By preventing oxygen uptake during milling, the argon atmosphere ensures that the final parts retain the excellent mechanical properties required for high-temperature applications.

Common Pitfalls to Avoid

The "High-Purity" Requirement

Using standard industrial argon is often insufficient for superalloys. The gas must be "high purity" to ensure that trace amounts of moisture or oxygen within the gas itself do not cause contamination.

System Integrity Risks

Because milling involves vibration and long durations, the mechanical seals of the milling jar are potential failure points. Even with high-purity argon inside, a poor seal can allow air ingress, rendering the protective atmosphere useless.

Making the Right Choice for Your Goal

To ensure the success of your powder metallurgy process, consider the following priorities:

- If your primary focus is Phase Stability: Ensure your argon source is certified high-purity to prevent the formation of oxide phases that disrupt the alloy's microstructure.

- If your primary focus is High-Temperature Performance: Maintain a strictly inert environment to avoid brittleness and ensure the final component can withstand thermal stress.

Control the atmosphere at the milling stage to guarantee the integrity of your final component.

Summary Table:

| Factor | Impact of Argon Protection | Consequence of Air Exposure |

|---|---|---|

| Chemical Stability | Prevents oxidation of Co-9Al-9W | Significant material degradation |

| Microstructure | Ensures phase purity after sintering | Formation of unwanted oxide phases |

| Surface Area | Protects high specific surface areas | Accelerated chemical reactivity |

| Performance | Maintains high-temperature strength | Increased brittleness and defects |

Elevate Your Powder Metallurgy Precision with KINTEK

Don't let oxidation compromise your alloy's performance. At KINTEK, we understand that high-performance materials like cobalt-based superalloys demand absolute environmental control. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, and Vacuum systems specifically designed to maintain the high-purity atmospheres your research requires.

Whether you need standard lab high-temp furnaces or fully customizable systems for unique milling and sintering needs, our engineering team is ready to support your success.

Contact us today to find your ideal thermal solution

Visual Guide

References

- Mónica Campos, J. M. Torralba. Enhancement of γ/γ’ Microstructured Cobalt Superalloys Produced from Atomized Powder by Creating a Harmonic Structure. DOI: 10.3390/met14010070

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What types of furnaces are specially designed for processing in inert atmospheres? Explore Sealed Systems for Oxidation-Free Results

- Why is an inert atmosphere important in heat treatment processes? Prevent Oxidation and Ensure Material Integrity

- What is the function of a controlled atmosphere in Violet Phosphorus research? Achieve High-Purity Material Restoration

- How does a high-temperature atmosphere sintering furnace ensure Eu2+ formation? Optimize Your Phosphor Synthesis

- What is a reducing atmosphere? Master Material Protection and Control

- What is a retort furnace and what are its key features? Discover Precision Heating for Superior Material Processing

- What role do atmosphere furnaces play in metal processing? Prevent Oxidation and Enhance Surface Properties

- What are the key benefits of precise temperature control in a controlled atmosphere furnace? Unlock Superior Quality and Efficiency