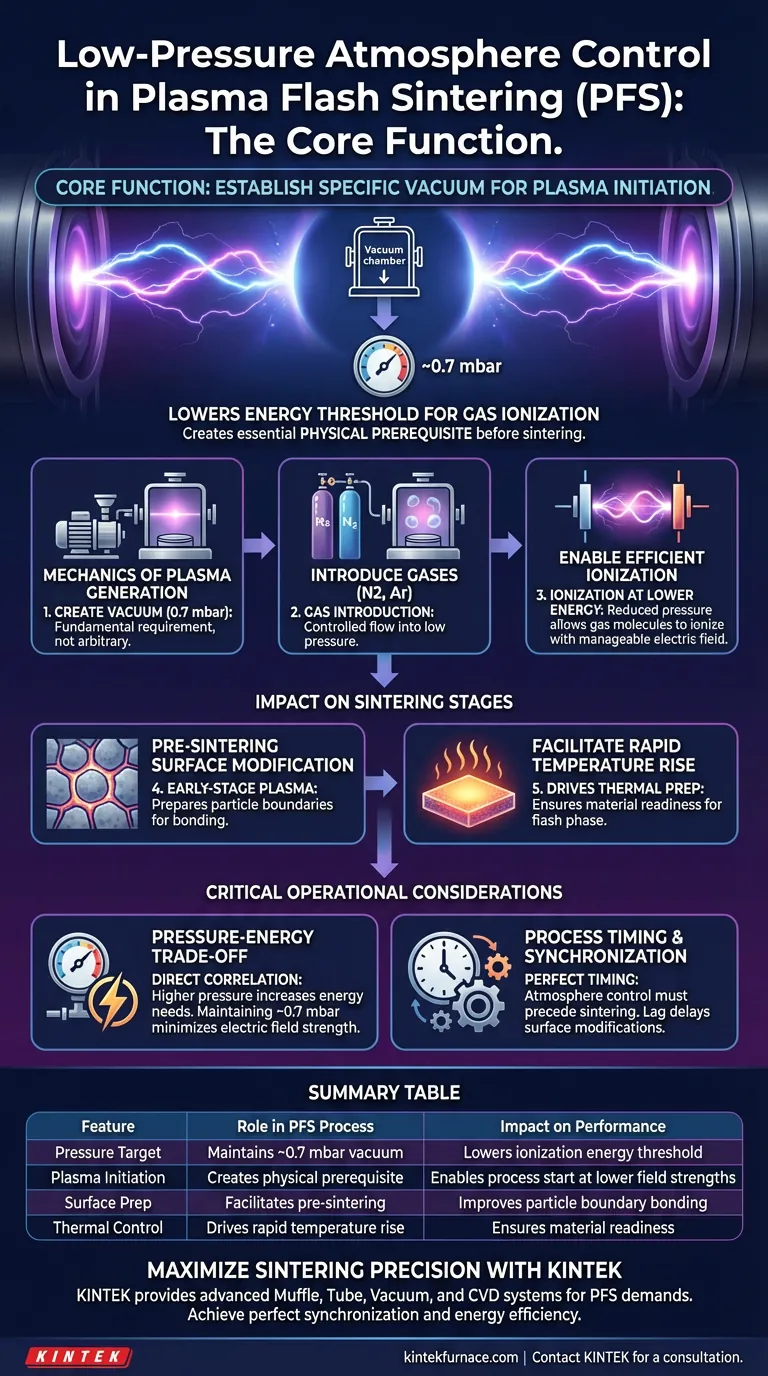

The core function of low-pressure atmosphere control equipment in the Plasma Flash Sintering (PFS) process is to establish the specific vacuum environment required to initiate plasma. By reducing chamber pressure to approximately 0.7 mbar, this equipment lowers the energy threshold needed to ionize process gases. This creates the essential physical conditions for plasma generation before the actual sintering phase begins.

Core Takeaway: This equipment does not merely remove air; it creates a "physical prerequisite" for the process. By maintaining a low-pressure environment, it allows gases to ionize at manageable electric field strengths, enabling crucial surface modifications and rapid heating prior to formal flash sintering.

The Mechanics of Plasma Generation

Creating the Physical Prerequisite

The primary objective of the control equipment is to achieve and maintain a specific low-pressure state, typically around 0.7 mbar.

This vacuum level is not arbitrary; it is the fundamental requirement for the process to function. Without this specific atmospheric condition, the subsequent physical reactions necessary for PFS cannot be initiated.

Enabling Efficient Ionization

Once the low-pressure environment is established, gases such as nitrogen or argon are introduced.

The reduced pressure plays a critical role in thermodynamics: it allows these gas molecules to ionize at significantly lower electric field strengths.

If the pressure were higher, the energy required to turn these gases into plasma would be prohibitive or technically unfeasible for the system.

The Impact on Sintering Stages

Pre-Sintering Surface Modification

The plasma generated by this low-pressure control is active before the formal flash sintering event takes place.

This early-stage plasma is responsible for modifying the surface of the material. It prepares the particle boundaries for the bonding that will occur later in the process.

Facilitating Rapid Temperature Rise

Beyond surface effects, the ionized gas environment drives rapid temperature elevation.

This ensures the material is thermally prepared for the intense energy release that characterizes the final flash sintering stage.

Critical Operational Considerations

The Pressure-Energy Trade-off

There is a direct correlation between the quality of the vacuum and the electrical energy required.

If the equipment fails to maintain the target low pressure (e.g., rising above 0.7 mbar), the electric field strength required to trigger ionization increases. This can lead to system strain or a failure to generate plasma altogether.

Process Timing and Synchronization

The atmosphere control must be perfectly synchronized with the sintering schedule.

Because the plasma must be generated before formal sintering, any lag in reaching the target pressure will delay the necessary surface modifications. This can result in uneven heating or incomplete sintering during the flash phase.

Making the Right Choice for Your Goal

To optimize your Plasma Flash Sintering results, consider how your atmosphere control supports your specific objectives:

- If your primary focus is Energy Efficiency: Ensure your equipment can reliably sustain 0.7 mbar to minimize the electric field strength required for ionization.

- If your primary focus is Material Quality: Verify that the equipment stabilizes the atmosphere early enough to allow for complete surface modification before the flash event.

Precise atmosphere control is the gatekeeper that transforms standard gas inputs into the active plasma required for high-performance sintering.

Summary Table:

| Feature | Role in PFS Process | Impact on Performance |

|---|---|---|

| Pressure Target | Maintains ~0.7 mbar vacuum | Lowers ionization energy threshold |

| Plasma Initiation | Creates physical prerequisite for gas ionization | Enables process start at lower field strengths |

| Surface Prep | Facilitates pre-sintering modifications | Improves particle boundary bonding |

| Thermal Control | Drives rapid and uniform temperature rise | Ensures material readiness for flash phase |

Maximize Your Sintering Precision with KINTEK

Precise atmospheric control is the difference between a failed cycle and a high-performance material. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Muffle, Tube, Vacuum, and CVD systems designed to meet the rigorous demands of Plasma Flash Sintering. Whether you need a standard solution or a customizable high-temp furnace for unique research needs, our technology ensures your lab achieves perfect synchronization and energy efficiency.

Ready to elevate your thermal processing? Contact KINTEK today for a customized consultation!

Visual Guide

References

- Eva Gil‐González, Luis A. Pérez‐Maqueda. Plasma‐flash sintering: Metastable phase stabilization and evidence of ionized species. DOI: 10.1111/jace.20105

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What factors should be considered when choosing a controlled atmosphere furnace? Ensure Optimal Performance for Your Materials

- What is the function of a high-pressure Argon atmosphere? Master Complex Alloy Purity with Precision Melting

- What is the role of a chemical reactor with thermogravimetric measurement in nitriding? Master AISI 1085 Kinetics

- What is the pressure range of an atmosphere box furnace under vacuum conditions? Find the Right Vacuum Level for Your Lab

- What are the risk mitigation strategies for atmosphere furnace operation? Ensure Safe and Efficient Lab Processes

- Why is the temperature control of a high-precision resistance furnace essential for B4C/Al composites? Gain Control

- What methods are used to implement inert atmospheres? Master Purge, Evacuation, and Sealing Techniques

- How does the experimental box type atmosphere furnace contribute to energy conservation and environmental protection? Discover Sustainable Lab Solutions