The achievable vacuum in an atmosphere box furnace varies significantly based on its design, ranging from a rough vacuum for basic gas purging to a high vacuum for sensitive material processing. A typical unit can achieve a negative gauge pressure of approximately -0.1 MPa for initial air removal, while specialized models can reach absolute pressures as low as 1 Pa or even 10⁻³ hPa (0.1 Pa) for high-purity applications.

The critical distinction is not just if an atmosphere furnace can create a vacuum, but the quality of that vacuum. The pressure level you can achieve directly dictates the types of processes you can run, separating simple inert gas purging from true high-purity material treatments.

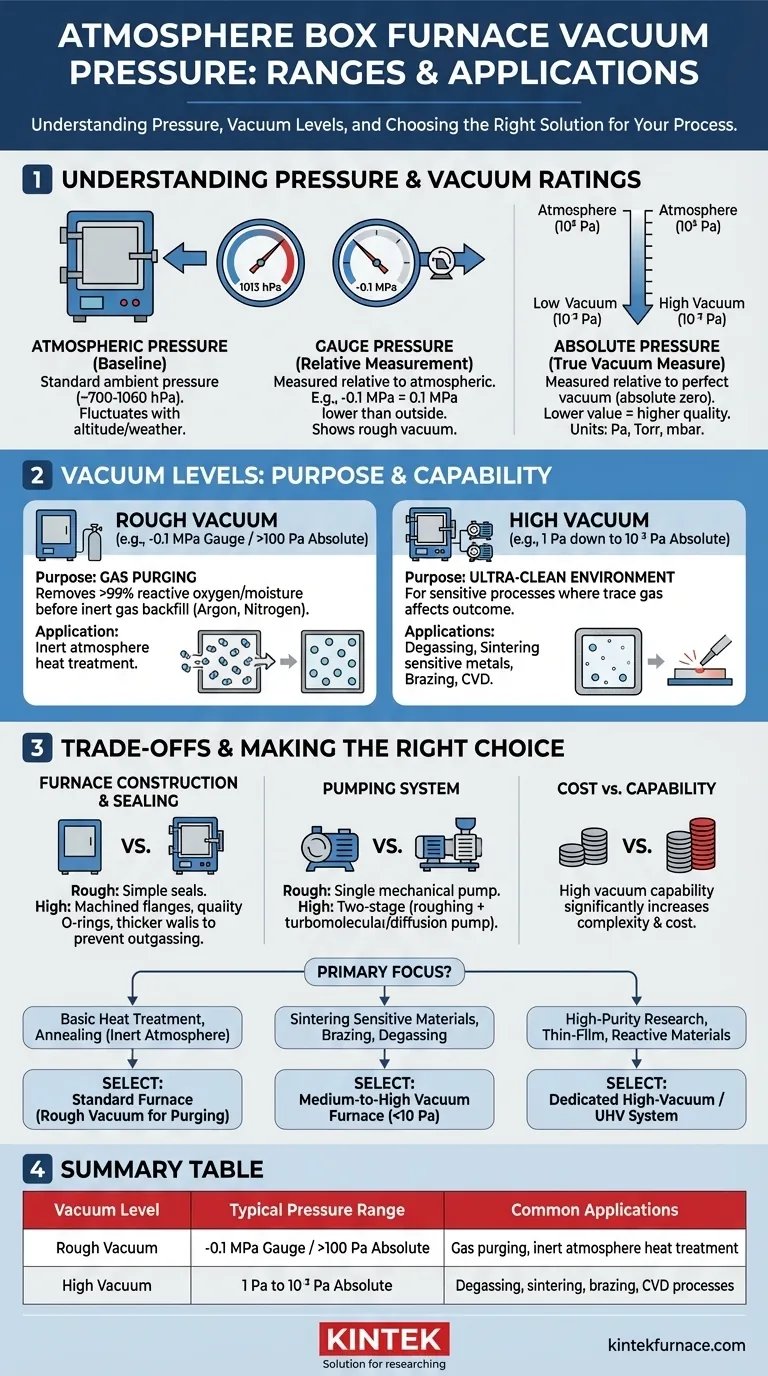

Understanding Furnace Pressure Ratings

To interpret manufacturer specifications, you must first understand how pressure and vacuum are measured. The terminology can be a source of significant confusion.

The Baseline: Atmospheric Pressure

A standard atmosphere box furnace, when not under vacuum or positive pressure, simply operates at the ambient atmospheric pressure. This typically fluctuates between 700 hPa and 1060 hPa depending on altitude and weather.

Gauge Pressure: A Relative Measurement

Many specifications list vacuum capability as a negative gauge pressure, such as -0.1 MPa.

This value is relative to the atmospheric pressure outside the furnace. A reading of -0.1 MPa indicates that the internal pressure is 0.1 MPa lower than the outside air, representing an almost complete removal of the atmosphere inside the chamber. It signifies a rough vacuum.

Absolute Pressure: The True Measure of Vacuum

For scientific and process control, absolute pressure is the definitive measurement. It is measured relative to a perfect vacuum (absolute zero pressure).

Common units for absolute pressure include Pascals (Pa), Torr, or millibar (mbar), which is equivalent to a hectopascal (hPa). A lower absolute pressure value means a higher quality vacuum. For example, 1 Pa is a much better vacuum than 100 Pa.

Vacuum Levels and Their Purpose

The level of vacuum you need is dictated entirely by your process goal. A furnace's vacuum capability is determined by its construction, seals, and pumping system.

Rough Vacuum (Approx. -0.1 MPa Gauge / >100 Pa Absolute)

This is the most common vacuum capability in a standard atmosphere furnace. Its primary purpose is not to conduct a process under vacuum, but to purge the chamber.

By evacuating the air, you remove over 99% of the reactive oxygen and moisture. You can then backfill the chamber with a high-purity inert gas, like argon or nitrogen, to create a controlled, non-oxidizing atmosphere for heat treatment.

High Vacuum (1 Pa down to 10⁻³ Pa)

Achieving a high vacuum requires a more robustly built furnace with superior seals and a more advanced pumping system. This level of vacuum is necessary for processes where even trace amounts of gas can affect the outcome.

Applications include degassing (removing trapped gases from a material), sintering highly sensitive powdered metals, brazing, and certain types of Chemical Vapor Deposition (CVD). Operating at this pressure ensures an ultra-clean environment.

Understanding the Trade-offs

Choosing a furnace based on its vacuum capability involves significant trade-offs in complexity and cost. Understanding these is key to avoiding over- or under-specifying your equipment.

Furnace Construction and Sealing

A furnace designed only for rough vacuum purging may use simple door gaskets. A high-vacuum furnace requires machined flange surfaces with high-quality O-rings and leak-tight ports for all connections. The chamber walls must also be thicker and made of materials that do not release gas under vacuum (a phenomenon called outgassing).

The Pumping System

A rough vacuum can be achieved with a single, relatively inexpensive mechanical pump (a rotary vane pump). High vacuum requires a two-stage system: a mechanical "roughing" pump that first creates the rough vacuum, followed by a high-vacuum pump (like a turbomolecular or diffusion pump) to reach the lower pressures.

Cost vs. Capability

The difference in cost is substantial. A furnace capable of reaching and holding a high vacuum can be several times more expensive than a standard atmosphere furnace that only offers a rough vacuum feature for purging. The additional cost comes from the advanced pumps, superior chamber engineering, and more complex control systems.

Making the Right Choice for Your Goal

Select your furnace based on the most demanding process you intend to run.

- If your primary focus is basic heat treatment, annealing, or hardening in an inert atmosphere: A standard furnace with a rough vacuum capability for purging is efficient and cost-effective.

- If your primary focus is sintering sensitive materials, brazing, or degassing parts: You require a furnace specified to achieve and hold a medium-to-high vacuum (e.g., below 10 Pa).

- If your primary focus is high-purity research, thin-film deposition, or working with extremely reactive materials: A dedicated high-vacuum or ultra-high vacuum (UHV) system is necessary, as even a high-end atmosphere furnace may not provide sufficient purity.

Ultimately, matching the furnace's vacuum performance to your specific material and process requirements is the key to achieving reliable and repeatable results.

Summary Table:

| Vacuum Level | Typical Pressure Range | Common Applications |

|---|---|---|

| Rough Vacuum | -0.1 MPa Gauge / >100 Pa Absolute | Gas purging, inert atmosphere heat treatment |

| High Vacuum | 1 Pa to 10⁻³ Pa Absolute | Degassing, sintering, brazing, CVD processes |

Need a high-temperature furnace tailored to your vacuum requirements? KINTEK specializes in advanced solutions for diverse laboratories, offering Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we provide deep customization to meet your unique experimental needs—ensuring precise vacuum control and reliable performance. Contact us today to discuss how we can enhance your lab's capabilities!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What is an atmosphere protection muffle furnace? Unlock Precise Heat Treatment in Controlled Environments

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation