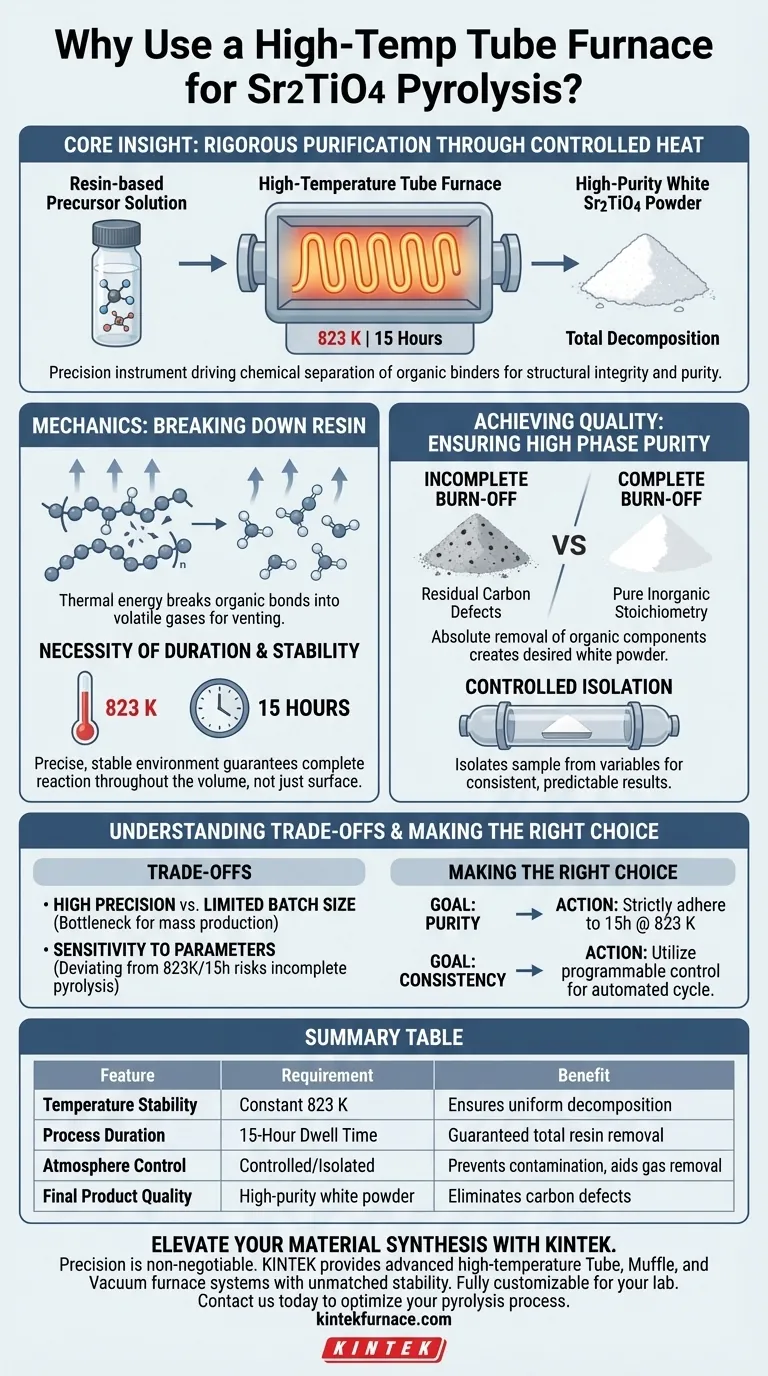

The primary function of a high-temperature tube furnace in this context is rigorous purification through controlled heat. It is utilized to subject resin-based precursor solutions to a specific thermal cycle—823 K for 15 hours—to achieve total decomposition of organic materials. This process is the deciding factor in transforming a raw mixture into high-purity, white Sr2TiO4 initial powders.

Core Insight: The tube furnace is not merely a heating element; it is a precision instrument used to drive the chemical separation of organic binders from inorganic ceramics. By maintaining a stable temperature over a long duration, it ensures the complete "burn-off" of resin components, which is essential for the structural integrity and purity of the final ceramic material.

The Mechanics of Precursor Purification

Breaking Down Resin Structures

The synthesis of Sr2TiO4 often begins with a resin-based precursor solution. While the resin acts as a necessary vehicle to mix the strontium and titanium elements, it must be completely eliminated to form the final ceramic.

The high-temperature tube furnace provides the thermal energy required to break the chemical bonds of these organic polymers. This process, known as pyrolysis, degrades the organic material into volatile gases that can be vented away from the sample.

The Necessity of Duration and Stability

Achieving high purity is not instantaneous. The primary reference specifies a processing time of 15 hours at 823 K.

A standard oven may fluctuate, but a tube furnace offers a precisely controlled thermal environment. This stability ensures that the material remains at the target temperature for the entire duration, guaranteeing that the reaction reaches completion throughout the entire volume of the powder, not just the surface.

Achieving Material Quality

Ensuring High Phase Purity

The ultimate goal of using this specific equipment is to produce high-purity white Sr2TiO4 powders. If organic carbon remains in the sample, the powder would likely appear gray or black and contain structural defects.

The tube furnace ensures that the "burn-off" is absolute. By fully removing the organic components, the remaining material consists solely of the desired inorganic stoichiometry required for subsequent processing.

Controlled Environmental Isolation

While the primary focus is heat, the design of a tube furnace—a sealed cylindrical chamber—isolates the sample from uncontrolled external variables.

This enclosure allows for a consistent reaction environment. Whether the specific protocol requires oxidation to remove carbon or simple thermal decomposition, the tube furnace creates a standardized zone where the removal of organic components occurs predictably and effectively.

Understanding the Trade-offs

Batch Size Limitations

Tube furnaces are generally designed for high precision rather than high volume. The cylindrical cavity restricts the amount of precursor powder you can treat in a single run. This makes them ideal for research and high-value synthesis but potentially creating a bottleneck for mass production.

Sensitivity to Process Parameters

The success of the pyrolysis hinges on exact adherence to the thermal profile. Deviating from the 823 K setpoint or shortening the 15-hour duration poses a significant risk. Insufficient heat or time will lead to incomplete pyrolysis, resulting in residual carbon contamination that compromises the dielectric or structural properties of the Sr2TiO4.

Making the Right Choice for Your Goal

To ensure the successful synthesis of Sr2TiO4 powders, apply the following principles:

- If your primary focus is Purity: Strictly adhere to the 15-hour dwell time at 823 K to ensure the complete removal of all resin-based organic markers.

- If your primary focus is Consistency: utilize the tube furnace's programmable control to automate the heating ramp and soak times, eliminating human error from the thermal cycle.

By leveraging the precise thermal control of a tube furnace, you convert a complex organic-inorganic mixture into a pristine ceramic foundation.

Summary Table:

| Feature | Requirement for Sr2TiO4 Pyrolysis | Benefit of Tube Furnace |

|---|---|---|

| Temperature Stability | Constant 823 K | Ensures uniform decomposition across the sample |

| Process Duration | 15-Hour Dwell Time | Guaranteed total removal of organic resin binders |

| Atmosphere Control | Controlled/Isolated | Prevents contamination and aids volatile gas removal |

| Final Product Quality | High-purity white powder | Eliminates carbon defects for superior stoichiometry |

Elevate Your Material Synthesis with KINTEK

Precision is non-negotiable when your research depends on high-purity Sr2TiO4. KINTEK provides advanced high-temperature Tube, Muffle, and Vacuum furnace systems specifically engineered to handle rigorous thermal cycles with unmatched stability. Backed by expert R&D and manufacturing, our solutions are fully customizable to meet your unique laboratory needs.

Ready to optimize your pyrolysis process? Contact us today for a custom consultation and discover how KINTEK can enhance your ceramic synthesis results.

Visual Guide

References

- Jinxing Yu, Xiaoxiang Xu. Fluorine-expedited nitridation of layered perovskite Sr2TiO4 for visible-light-driven photocatalytic overall water splitting. DOI: 10.1038/s41467-024-55748-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a lab tube furnace? The Ultimate Guide to Precision High-Temp Processing

- How does a tube furnace convert energy to achieve heating? Master Precise Thermal Control for Your Lab

- What conditions do tube furnaces provide for Au-Seeded TiO2 nanowires? Master Precision Thermal Synthesis

- How does high-temperature tube furnace programmed control influence porous carbon? Expert Pore Geometry Insights

- What is the core function of a multi-zone tube furnace in 2D superlattice synthesis? Optimize Your CVD Process

- What is a tubular furnace and what are its primary uses? Essential for High-Temperature Precision and Uniformity

- What are the space-saving benefits of a tube furnace? Maximize Lab Efficiency with Compact Design

- Why is a high-vacuum tube furnace required for sintering aluminum composites? Achieve Superior Purity and Density